Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

Product

Project Case

-

DOING® Group|100 TPD Continuous Tire Pyrolysis Plants Installed for Repeat Client in China

-

Customized 1 Ton/Day Continuous Plastic Pyrolysis System Delivered for Korean Client

-

DOING DY-15 Waste Tire Pyrolysis Machine Project Successfully Installed in Kenya

-

DOING 45,000 Tons/Year Waste Plastic Pyrolysis Project in Vietnam Successfully Commissioned

-

DOING Tire & Plastic Pyrolysis Distillation Plant Successfully Installed in Fiji

-

DOING 50TPD Continuous Oil Sludge Pyrolysis Production Line Successfully Installed in China

-

DOING Installed 15-Ton Tank Bottom Sludge Pyrolysis Equipment for Colombian Repeat Client

-

DOING 30TPD Mazut Oil Distillation Plant Successfully Installed in Kazakhstan

-

-

DOING Three 15-ton Batch Tire Pyrolysis Units in Myanmar On-site Installation Experience

How many kinds of pyrolysis plants are there? How to choose a suitable one?

2023-02-23 / Continuous Pyrolysis plant / Leave Message / Chat Online

Pyrolysis Plant is a popular machine for recycling municipal solid waste like waste tires and plastic. Up to now, there are mainly two kinds of pyrolysis plant on the market, batch type pyrolysis plant and fully automatic continuous pyrolysis plant.

Then how to choose the most suitable pyrolysis plant? Please go on reading the pyrolysis plant introduction to find the answers.

1. Batch type waste tire/plastic pyrolysis plant

Batch type waste tire/plastic pyrolysis plant has a simple structure, one machine with multiple functions, and can process waste plastics, waste rubber tires, oil sludge, coal tar oil, etc., the process time is one day one batch, the feeding method is the whole tire, and the operation is flexible and adaptable. And the reactor is in a cold-hot-cold alternating state.

The batch type waste tyres pyrolysis plant picture

The batch type waste tyres pyrolysis plant picture

The processing capacity of a single batch pyrolysis machine is from 100kg to 15 tons. This kind of batch pyrolysis plant is the hot and cost effective choice for the customers who just entered the pyrolysis industry and has lower requirements for the labor intensity.

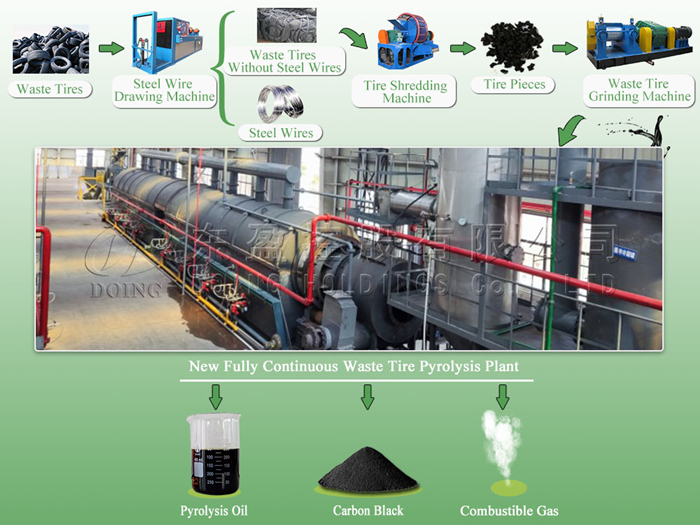

2. Fully automatic continuous waste tire/plastic pyrolysis plant

Compared with the batch type, the single production line processing capacity of the continuous type is large, and it can handle from 15-50tpd of rubber powder. While feeding and discharging at the same time, continuous operation saves labor costs and improves efficiency. The entire production is under sealed conditions operation, completely avoiding the danger of open feeding and slag discharge; using indirect heating to avoid direct contact between the reactor and the furnace, prolonging the life of the reactor; continuous operation relies on intelligent control, making the production operation accurate, stable and labor-saving.

The continuous pyrolysis plant picture

The continuous pyrolysis plant picture

The fully automatic continuous waste tire/plastic pyrolysis plant is suitable for customers who have big investment and high automatic control requirements.

Henan Doing specializes in manufacturing waste tire/plastic pyrolysis plant and related waste engine oil/pyrolysis oil to diesel distillation plant, etc. 12+ years of technical precipitation have enabled us to have strong research and development capabilities and equipment manufacturing capabilities. We have been providing various pyrolysis plants and related solutions. Welcome to contact us for enquiry and visit the factory for cooperation.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.