Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

Product

Project Case

-

DOING® Group|100 TPD Continuous Tire Pyrolysis Plants Installed for Repeat Client in China

-

Customized 1 Ton/Day Continuous Plastic Pyrolysis System Delivered for Korean Client

-

DOING DY-15 Waste Tire Pyrolysis Machine Project Successfully Installed in Kenya

-

DOING 45,000 Tons/Year Waste Plastic Pyrolysis Project in Vietnam Successfully Commissioned

-

DOING Tire & Plastic Pyrolysis Distillation Plant Successfully Installed in Fiji

-

DOING 50TPD Continuous Oil Sludge Pyrolysis Production Line Successfully Installed in China

-

DOING Installed 15-Ton Tank Bottom Sludge Pyrolysis Equipment for Colombian Repeat Client

-

DOING 30TPD Mazut Oil Distillation Plant Successfully Installed in Kazakhstan

-

-

DOING Three 15-ton Batch Tire Pyrolysis Units in Myanmar On-site Installation Experience

Can tires be turned into fuel? What machine can recycle waste tires into oil?

2023-03-21 / Continuous Pyrolysis plant / Leave Message / Chat Online

In a sealed environment, the polymer with unsaturated bonds in the main chain of the waste rubber content of waste tires can be broken by high temperature, and the waste tires can be turned into fuel oil(TDF-Tire Derived Fuel), carbon black, syn-gas and steel wire products by pyrolysis machine.

How does the pyrolysis machine recycle waste tires into oil? The specific working processing is as follows:

First, use an automatic feeder or manually feed waste tires into the reactor, and after the completion of the feeding, close the reactor door.

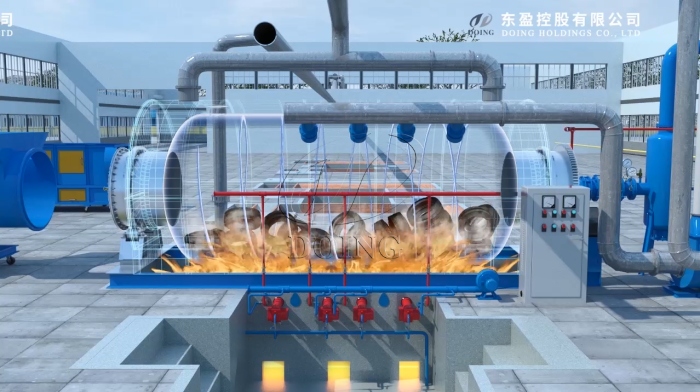

Waste pyrolysis plant reactor

Waste pyrolysis plant reactor

Turn on the burner to preheat the reactor. After preheating for a period of time, tail gas will be generated. Then turn on the tail gas spray gun to use the generated tail gas to heat the reactor, which can save more than half of the fuel.

After reaching a certain temperature, the oil gas in the tire will be cracked, and the cracked oil gas will be cooled into liquid fuel through the condensation system and collected in the oil tanks.

When the waste tire to oil pyrolysis process is over, turn off all the burners, turn on the cold air system to cool down the reactor. Then turn on the negative pressure system to pump out the remaining oil gas in the reactor, cool the remaining oil gas into liquid fuel through the cooling system, which not only improves the oil yield, but also ensures that it is safe and odorless when opening the furnace door.

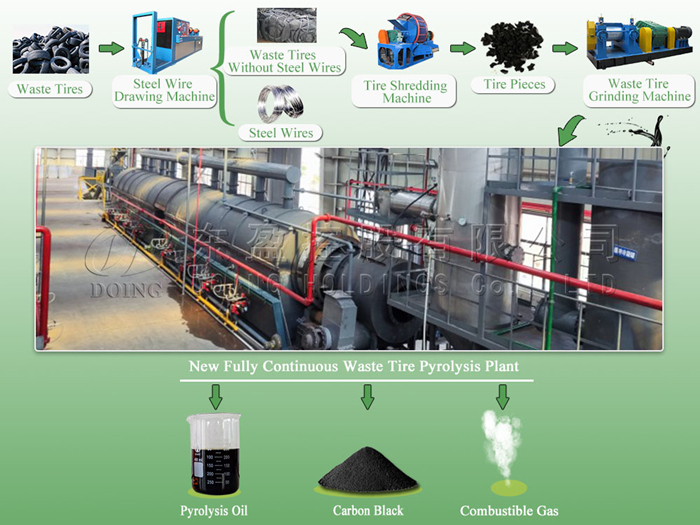

The process of continuous waste tyres pyrolysis plant

The process of continuous waste tyres pyrolysis plant

And then discharge and collect the carbon black through the carbon black elevator or air transport system, and draw out the steel wire in the reactor through a hoist or steel wire puller. But if you adopt the fully continuous pyrolysis machine, you need to pretreat the waste tires, draw the steel wire out and cut the waste tires into small blocks. And you don't need to stop the pyrolysis machine for discharging.

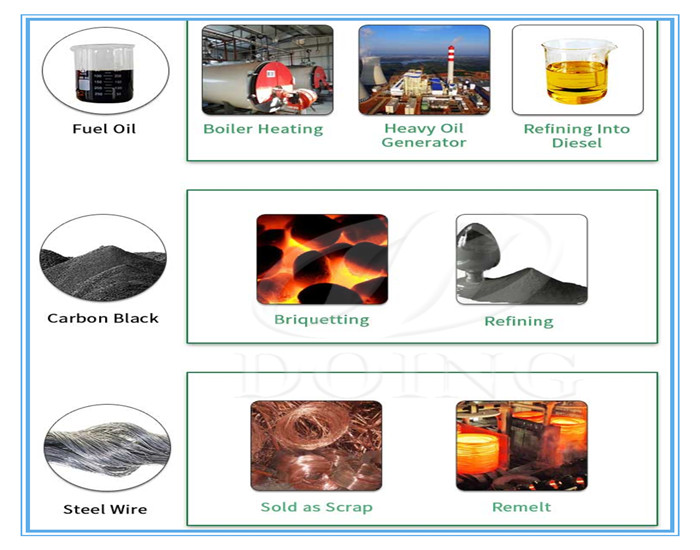

Turn waste tires into tire derived fuel is one of the main ways to dispose of waste tires. Relevant data show that the combustion calorific value of waste tires is about 7000-8000 kcal/kg, which is 25%-50% more than coal, 100%-200% more than wood, and almost as much as oil. In terms of price, it is cheaper than burning coal, while producing cleaner emissions. And thanks to the "high calorific value", waste tires have also become a very good alternative fuel for energy-intensive industries such as cement plants, power plants, and paper mills. And the tire oil can also be further refined into diesel by our waste/crude oil distillation plant.

The applications of pyrolysis product

The applications of pyrolysis product

The waste tires into fuel recycling industry is an industry with unlimited business opportunities. If you want to know more about tires recycled into fuel, please contact us in time for more details about the waste tire pyrolysis machine.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.