Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

Product

Project Case

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

-

50TPD fully continuous waste tyre pyrolysis plant installed in Russia

-

50TPD continuous waste rubber tire pyrolysis machine put into operation in India!

-

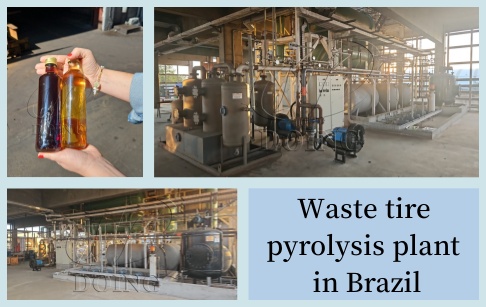

50 TPD fully continuous pyrolysis plant project installed in Brazil

What types of pyrolysis plant are there, and what are the characteristics of each?

2022-08-02 / Continuous Pyrolysis plant / Leave Message / Chat Online

There are three main types of pyrolysis plants in the whole market: batch pyrolysis plant, semi-continuous pyrolysis plant, and fully continuous pyrolysis plant. These three types of pyrolysis plants have different characteristics, please read on to choose the most suitable type of pyrolysis plant for you.

1.Batch pyrolysis plant

It means to pyrolyze the solid waste raw materials batch by batch. We have many models of batch pyrolysis plant, the daily capacity includes 1/5/10/12/15TPD, etc. If you want to test it before starting the big pyrolysis project, we also have 100/500kg and 1 ton small testing pyrolysis plant for you to choose, and we make container types of these small machines. It can save your installation cost. When you receive the machine, you only need to find a factory land to put the machine then start operating.

DOING batch type pyrolysis plant

DOING batch type pyrolysis plant

For batch pyrolysis plant, it is the most popular type purchased by most of our clients. We already exported batch pyrolysis plants to over 90 countries all over the world. The batch pyrolysis plant relies on competitive cost, high effect and easy to operate to get the reputation. The same batch pyrolysis plant can both recycle used tires and waste plastic, and you could also use it to recycle other solid wastes such as medical wastes, oil sludge wastes and so on.

2. Semi-continuous pyrolysis plant

It means you can keep feeding raw materials when you operate it. If your raw material is rubber powder or shred plastic or semi-liquid oil sludge, you could consider the semi-continuous pyrolysis plant. It has higher processing efficiency than batch pyrolysis plant.

This Semi-continuous type pyrolysis plant is also designed to meet some countries' requirements. For example, in India, many states don’t allow the batch pyrolysis plant.

Semi-continuous type pyrolysis plant

Semi-continuous type pyrolysis plant

3. Fully continuous pyrolysis plant

Fully continuous pyrolysis plant is a new trend all over the world, it can keep feeding and keep discharging, the whole process can keep two months working no stop. All systems obtain advanced technology, which can save lots of labor and get the highest effect. The PLC control system will help you control the whole factory in fully automatic condition.

Fully continuous type pyrolysis plant

Fully continuous type pyrolysis plant

The daily capacities include 15/20/30/40/50TPD, now it can both recycle tire rubber powder and shredded plastic. The machine cost of fully continuous pyrolysis plant is higher than batch type. But at the same time, it can also help you obtain more final products and higher profits. If you want to consider fully continuous pyrolysis plant, you’d better prepare more raw materials to ensure enough feeding when operating the machine. Now our fully continuous pyrolysis plants have been already exported to Italy, Kazakhstan, Thailand, Brazil, Russia, India and so on.

If you are interested in one of these three types of pyrolysis plants, please don’t hesitate to let us know. And our sales manager and engineer team can also customize you suitable pyrolysis plant solutions according to your situation!

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.