Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

Project Case

-

-

DOING Three 15-ton Batch Tire Pyrolysis Units in Myanmar On-site Installation Experience

-

India 50TPD Fully continuous rubber pyrolysis machine installed

-

DOING 15 TPD semi-continuous tire pyrolysis equipment installed in Indonesia

-

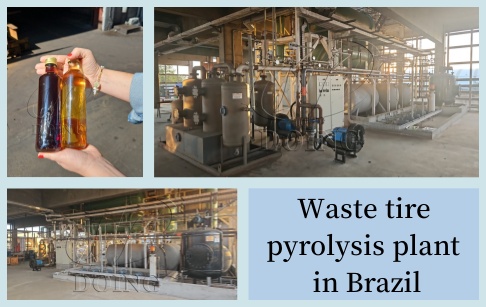

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

Product

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

Malaysia successfully installed two sets of DY-S-10 oil sludge pyrolysis machine manufactured by DOING

2025-11-06 / In Asia / Leave Message / Chat Online

In October 2025, Malaysia successfully installed two sets of DY-S-10 oil sludge pyrolysis machine manufactured by DOING. This is a video of the installation and operation.

Customer Journey and Installation Process

The Malaysian client first discovered DOING semi continuous oil sludge pyrolysis machine through an online case study. Impressed by the positive results from other installations, they contacted DOING for further inquiries. Following a site visit to DOING factory, the client was highly satisfied with the equipment quality and technological capabilities.

DOING business manager provided comprehensive support, assisting the client through all necessary approvals and paperwork. By June 2023, the two parties finalized the deal. DOING delivered two two sets of DY-S-10 oil sludge pyrolysis machine to Malaysia in December 2023.

Shipment of DOING semi-continuous oil sludge pyrolysis machine to Malaysia

Shipment of DOING semi-continuous oil sludge pyrolysis machine to Malaysia

Key Features of the Oil Sludge Pyrolysis Equipment

1.Two Sets of DY-S-10 Oil Sludge Pyrolysis Machine Reactors: The core of the system, designed to efficiently process large quantities of oil sludge into fuel oil, carbon black, and gas. The reactors operate at optimal temperatures to ensure maximum oil yield.

2.Conveyor Feeding System: Ensures smooth,consistent and rapid feeding of oil sludge into the pyrolysis reactors, improving operational efficiency.

3.Heavy Oil Burner: This burner enhances combustion efficiency, making the pyrolysis process more energy-efficient and reducing fuel consumption.

Malaysia oil sludge recycling pyrolysis machine project

Malaysia oil sludge recycling pyrolysis machine project

4.Vacuum Negative Pressure System: A critical safety feature that ensures the entire operation is safe, by maintaining a negative pressure environment, which minimizes the risk of leaks or explosions.

5.Carbon Black Lifter: Due to Malaysia’s strict environmental standards, this device helps to collect carbon black effectively, preventing leaks and contamination.

6.Environmental Systems: Includes a tail gas deodorization system and a desulfurization tower shared by both oil sludge pyrolysis machines, ensuring that exhaust emissions meet Malaysia’s environmental regulations.

7.Customized PLC System: The PLC system enhances automation and improves operational efficiency. It enables precise control of the entire pyrolysis process, ensuring optimal performance and minimizing downtime.

Malaysia oil sludge recycling pyrolysis machine project

Malaysia oil sludge recycling pyrolysis machine project

Installation and Operational Support

In early 2024, DOING dispatched a team of engineers to Malaysia for on-site technical guidance. Their mission was to ensure the correct installation of one of the oil sludge pyrolysis machines, with a focus on safety, efficiency, and performance. The first oil sludge pyrolysis unit operated smoothly and successfully. DOING provided the Malaysian customer team with detailed training on installation procedures, operating protocols, and maintenance procedures, equipping them with the knowledge and skills required for safe, efficient, and independent operation.

Following the installation and skills training provided by DOING engineers, the Malaysian customer's engineering team was able to complete the installation of the second oil sludge semi continuous pyrolysis machine, in conjunction with remote technical guidance from DOING engineers. This flexible support model allowed for efficient installation while ensuring that both machines were operating smoothly. By 2025, the system was fully operational, and the client provided valuable feedback, including a video showcasing the successful operation of both machines.

DOING provide service

DOING provide service

The successful installation of two sets of DY-S-10 oil sludge pyrolysis machine in Malaysia not only highlights the feasibility and efficiency of DOING pyrolysis machine in transforming waste into valuable resources but also underscores DOING commitment to providing comprehensive support to customers from equipment installation to final delivery. In the future, DOING looks forward to providing more advanced waste treatment solutions to Malaysia and other regions. Please feel free to contact DOING.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.