Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

Project Case

-

-

DOING Three 15-ton Batch Tire Pyrolysis Units in Myanmar On-site Installation Experience

-

India 50TPD Fully continuous rubber pyrolysis machine installed

-

DOING 15 TPD semi-continuous tire pyrolysis equipment installed in Indonesia

-

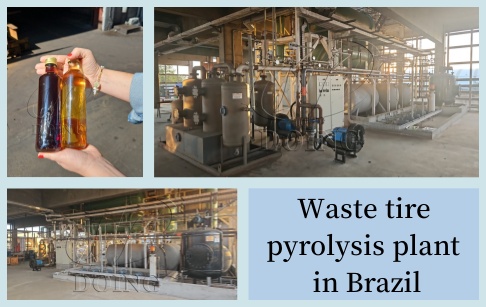

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

Product

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

India 50TPD Fully continuous rubber pyrolysis machine installed

2025-08-17 / In Asia / Leave Message / Chat Online

In the evolving landscape of waste management and renewable energy, DOING Company, a renowned manufacturer of pyrolysis machines, has once again demonstrated its prowess with the successful installation of a 50TPD fully continuous rubber pyrolysis machine in India in July, 2025.

India fully continuous rubber pyrolysis machine installed

India, with its abundant waste rubber resources, offers tremendous potential for recycling rubber tires into valuable products like fuel oil and carbon black. The client, a prominent Indian company specializing in reclaimed rubber, aimed to scale their business and explore innovative projects. After a detailed assessment and comparison with competitors, the client chose DOING’s continuous tire pyrolysis machine due to its impressive performance and competitive pricing. The customer visited the two operation sites on April 29, 2023, and witnessed the efficient operation of DOING's pyrolysis equipment under actual working conditions. Finally, the customer signed a contract with DOING on November 23, 2023.

India 50TPD Fully continuous rubber pyrolysis machine

The installed 50 t/d fully continuous rubber pyrolysis machine is designed for efficient and continuous operation and responds to the tire recycling policy promoted by the Indian government. Below are key details of the equipment configuration:

Pyrolysis Reactor: The core component where the pyrolysis process takes place, designed for continuous operation to ensure high - efficiency conversion of waste rubber into valuable products.

Condensation System: Converts the pyrolysis vapours into liquid oil, with advanced condensation technology maximising oil yield.

Safety Water Seal System: A crucial safety feature that prevents backfire and ensures smooth gas flow, guaranteeing the safe operation of the entire system.

Oil Storage and Transportation System: Stores the produced oil and facilitates its transportation, ensuring convenient and safe handling of the end product.

Slag Discharge System: Efficiently discharges the residual slag from the pyrolysis process, maintaining the system's cleanliness and enabling continuous operation.

Tail Gas Treatment System: Treats the exhaust gases to meet environmental standards, ensuring the project's eco - friendly operation.

Smoke Treatment System: Further processes the emissions to reduce pollutants, enhancing the environmental performance of the project.

Heavy Oil Burner: Utilises heavy oil as fuel to provide the necessary heat for the pyrolysis process, ensuring stable and efficient operation.

India 50TPD Fully continuous rubber pyrolysis machine equipment configuration

The successful installation of this 50TPD fully continuous rubber pyrolysis project in India further solidifies DOING's position as a leading provider of pyrolysis technology and equipment in the worldwide market.

DOING fully continuous pyrolysis machine manufacturer

Looking ahead, DOING Company remains committed to delivering high - quality products and services. Our sales team, production centre, logistics department, and after - sales service team will continue to work in close coordination. We are dedicated to meeting the diverse needs of our clients, ensuring timely delivery of equipment, and providing comprehensive support throughout the waset to energy pyrolysis project lifecycle.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.