Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

Project Case

-

-

DOING Three 15-ton Batch Tire Pyrolysis Units in Myanmar On-site Installation Experience

-

India 50TPD Fully continuous rubber pyrolysis machine installed

-

DOING 15 TPD semi-continuous tire pyrolysis equipment installed in Indonesia

-

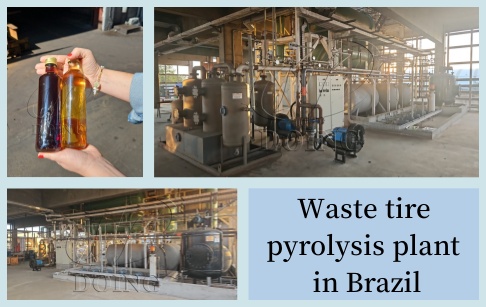

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

Product

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

DOING 15 TPD semi-continuous tire pyrolysis equipment installed in Indonesia

2025-07-10 / In Asia / Leave Message / Chat Online

On May 22, 2025, DY-S-15 tire pyrolysis equipment customized by a Singaporean customer was installed and debugged according to the standard process at the Indonesian project site. The following is a video of the installation and commissioning of the semi-continuous tire pyrolysis equipment in Indonesia:

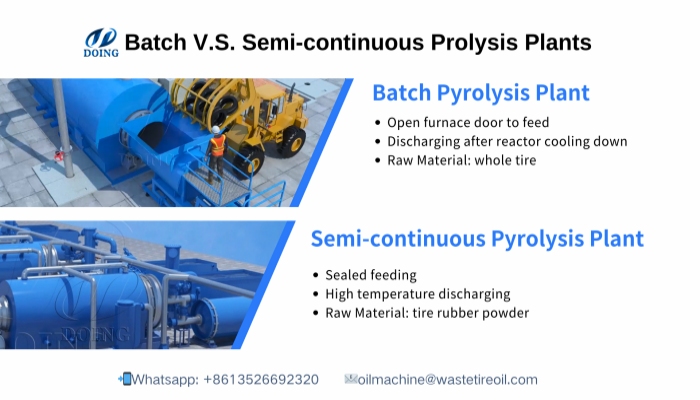

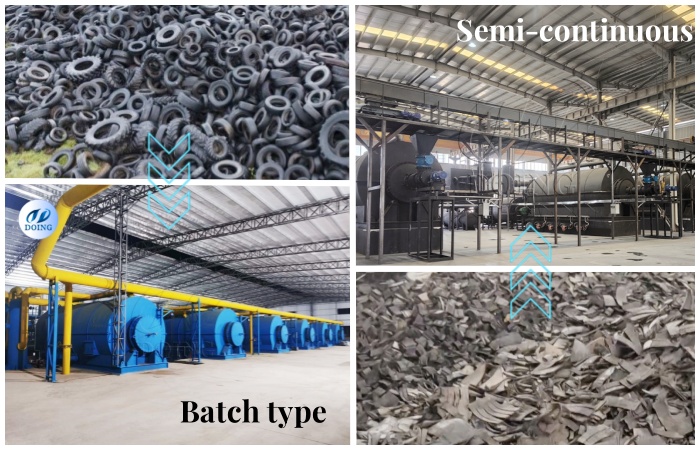

DOING provides comprehensive support to this Singaporean customer, from scheme design to delivery and loading to initial installation of the equipment to the commissioning stage. This Singaporean customer wants high-efficiently pyrolysis equipment, and our business manager recommended the semi-continuous tire pyrolysis equipment and fully-continuous tire pyrolysis equipment for him, which significantly improve production efficiency compared with batch type tire pyrolysis plant. Compared with the fully continuous pyrolysis equipment, the semi-continuous equipment is more affordable. The customer finally chose the semi-continuous pyrolysis tire equipment based on his processing capacity and budget.

Batch and semi-continuous pyrolysis equipment difference

Batch and semi-continuous pyrolysis equipment difference

The feeding link of the semi-continuous tire pyrolysis equipment has requirements for the material size. DOING also specially provides customers with tire crushing rubber powder equipment. Before pyrolysis, the waste tires are crushed and ground into rubber powder of about 16-20 meshes to facilitate subsequent pyrolysis reactions.

Differences in raw materials between batch and semi-continuous pyrolysis equipment

Differences in raw materials between batch and semi-continuous pyrolysis equipment

After the semi-continuous tire pyrolysis equipment arrived in Indonesia, DOING arranged a team of professional engineers to go to the Indonesian site to guide the correct installation, assist in debugging the equipment, and train customer operators to use the tire pyrolysis equipment correctly. Even after the trial run, DOING is still committed to providing timely maintenance and technical support to solve any problems that may arise.

DOING provide perfect service for customers

DOING provide perfect service for customers

Relying on its independent research and development strength, DOING has designed skid-mounted, batch, semi-continuous and fully automatic continuous series of pyrolysis equipment, which have been sold to more than 90 countries and regions at home and abroad. These pyrolysis equipment are widely used in waste tires, plastics, aluminum plastics, oily sludge, oily diatomaceous earth, coal tar residue, oil-based rock cuttings, domestic waste, construction waste, medical waste, and other solid waste and hazardous waste fields. The equipment performance and service are well received by users. Welcome to consult related equipment.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.