Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

News

-

DOING News

-

Industry News

Product

Project Case

-

India 50TPD Fully continuous rubber pyrolysis machine installed

-

DOING 15 TPD semi-continuous tire pyrolysis equipment installed in Indonesia

-

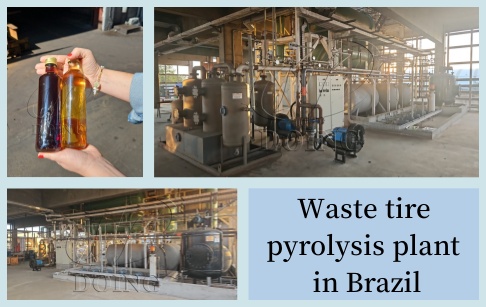

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

Is Tire Pyrolysis Environmentally Friendly?

2025-07-22 / Industry News / Leave Message / Chat Online

Tire pyrolysis, a process that breaks down waste tires into fuel, oil, and other byproducts through high-temperature heating in the absence of oxygen, has garnered significant attention as a solution for waste tire management. However, the question of whether tire pyrolysis is environmentally friendly remains a topic of debate.

Tire pyrolysis products

Actually, Tire Pyrolysis Process has both potential environmental benefits and risks, making its "environmental friendliness" context-dependent.

Potential Environmental Benefits

Waste Reduction: Tire pyrolysis effectively addresses the issue of waste tire disposal. Traditional landfilling of waste tires occupies land resources, poses fire risks, and creates breeding grounds for pests. Pyrolysis can convert waste tires into useful products, reducing their environmental impact.

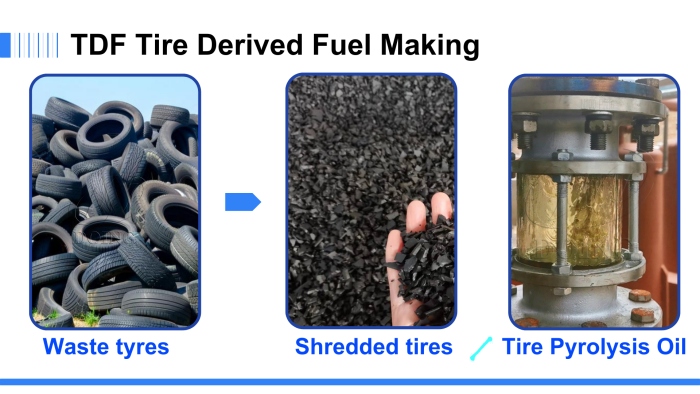

Resource Recovery: Tires are primarily composed of non-renewable petroleum-based materials. Through pyrolysis, waste tires can be transformed into valuable resources such as pyrolysis oil, carbon black, and steel wires. Pyrolysis oil can be further refined into diesel, carbon black can be used in tire manufacturing and other industries, and steel wires can be recycled in metallurgy and other sectors, achieving resource recycling.

Applications of tire pyrolysis products

Lower Greenhouse Gas Emissions Compared to Incineration: Unlike incineration, which releases large amounts of carbon dioxide and other pollutants, pyrolysis produces fewer direct emissions when properly controlled. This helps mitigate climate change.

Waste tire recycling methods

Environmental Risks

Pollutant Emissions: If not properly managed, the pyrolysis process can release toxic gases such as sulfur compounds and dioxins, as well as volatile organic compounds (VOCs), which can harm air quality and human health. The liquid byproducts of pyrolysis may contain heavy metals and carcinogens, posing risks of soil and water contamination if mishandled.

Energy Use: Tire pyrolysis requires significant energy input. In unregulated facilities often reliant on fossil fuels, the energy consumption of the pyrolysis process can increase carbon footprints, offsetting its environmental benefits.

Regulatory Compliance: In poorly regulated environments, operators may neglect emission controls to cut costs, leading to severe local pollution.

Environmentally Friendly Tire Pyrolysis Plant Solution Provided by Henan DOING Company

When tire pyrolysis process is conducted with advanced technologies and strict environmental management measures, its environmental benefits can be maximized while risks minimized.

As a professional manufacturer of pyrolysis machines, DOING Company is committed to developing environmentally friendly and efficient tire pyrolysis technologies. Our tire pyrolysis machine features the following advantages:

High Efficiency and Energy Savings:

The gas recovery system equipped with DOING Brand tire pyrolysis machine mainly recycles the non-condensable combustible gas (mainly composed of hydrogen, carbon monoxide, carbon dioxide and hydrocarbons) generated during the tyre pyrolysis process, and uses it for heating the pyrolysis furnace or as fuel for other industrial heating after purification.

The recovered gas replaces traditional fuels (such as diesel and heavy oil) to reduce carbon emissions and energy consumption. And the recovered gas can fully meet the heating needs of the tire pyrolysis process and reduce operating costs.

DOING waste tire pyrolysis machine exhaust gas recovery

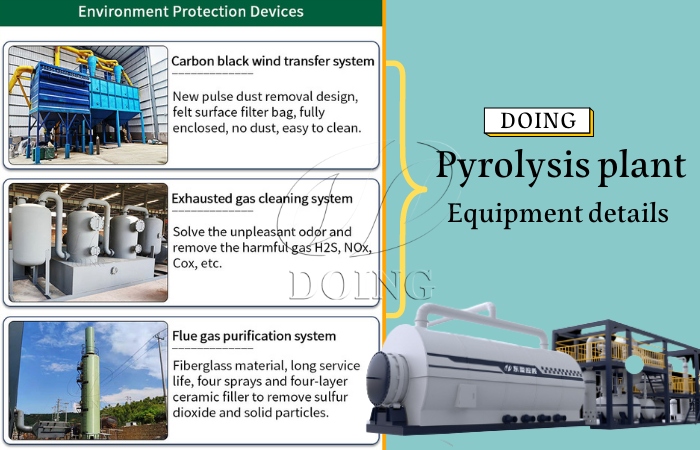

Low Pollutant Emissions: Equipped with highly efficient gas treatment devices, such as desulfurization, denitrification, and dust removal equipment, our tire pyrolysis machines can effectively remove harmful substances from exhaust gases, ensuring emissions meet environmental standards.

DOING tire pyrolysis machine environment protection devices

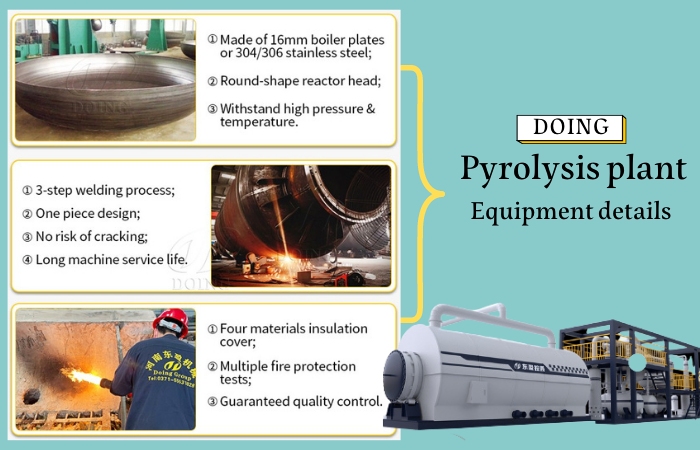

Safe and Stable Operation: Our tire pyrolysis machine is designed with multiple safety protection measures, such as the selection of high-quality equipment to manufacture steel, weld detection, explosion-proof valve/safety valve/negative pressure system and other configurations to ensure that the pyrolysis equipment delivered by DOING Company operates stably during the tire pyrolysis process and minimize the risk of accidents.

DOING waste tire pyrolysis machine details

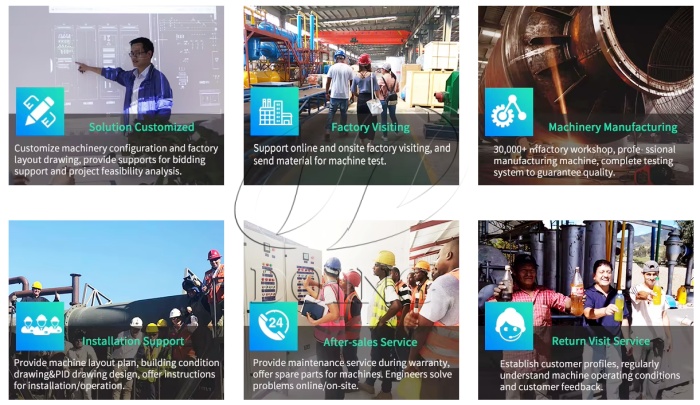

Comprehensive After-Sales Service: We provide one-stop after-sales support, including equipment installation, commissioning, training, and maintenance, to ensure stable operation of tire pyrolysis machines and help customers achieve efficient and eco-friendly waste tire processing.

DOING tire pyrolysis machine manufacturer

In conclusion, tire pyrolysis can be environmentally friendly when conducted with advanced technologies, strict environmental management, and effective regulatory oversight. To learn how DOING Company’s pyrolysis machines can help you achieve efficient and eco - friendly waste tire processing with high efficiency, low pollutant emissions, and comprehensive after - sales service, contact us for more details.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.