Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

News

-

DOING News

-

Industry News

Product

Project Case

-

India 50TPD Fully continuous rubber pyrolysis machine installed

-

DOING 15 TPD semi-continuous tire pyrolysis equipment installed in Indonesia

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

What is the difference between pyrolysis and combustion for waste treatment?

2025-07-31 / Industry News / Leave Message / Chat Online

Waste management is an essential aspect of protecting our environment. Two of the most common methods for treating waste are pyrolysis and combustion. While both are both thermal processes used for waste treatment, but they differ significantly in terms of conditions, products, and environmental impact. This article explains the differences between pyrolysis and combustion for waste treatment and how DOING pyrolysis equipment can be an effective solution for managing waste.

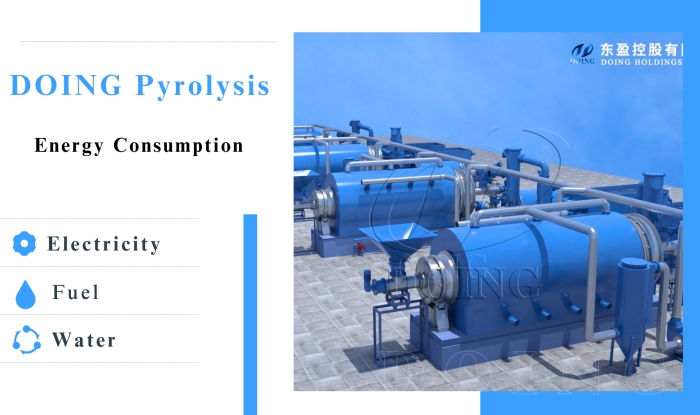

1. Definition & Process Conditions

Pyrolysis: Occurs in an oxygen-free or low-oxygen atmosphere (≤5% oxygen) at 300–800°C. The process uses thermal decomposition—breaking down organic waste into smaller molecules without oxidation, relying on controlled heating rather than burning. DOING pyrolysis equipment are engineered with airtight reactors to maintain strict oxygen control, ensuring efficient decomposition of waste.

DOING waste recycling pyrolysis equipment process

DOING waste recycling pyrolysis equipment process

Combustion: Operates in an oxygen-rich environment (using air) to fuel rapid oxidation. It requires high temperatures (800–1,200°C) to burn waste completely, with the reaction releasing heat as its primary energy output.

2.Products

| Parameter | Pyrolysis | Combustion |

| Liquids | Pyrolysis oil(a fuel substitute, e.g., for boilers or generators) | None (water vapor if moisture present) |

| Solids | Char/Biochar/carbonblack(used in rubber, construction, or as a soil amendment) | Ash (inorganic non-combustible residues) |

| Gases | Syngas(used to power the pyrolysis process itself) | CO₂, H₂O, NOx, SOx (if present in waste) |

| Energy Output | Liquid & gaseous fuels | Direct heat/steam/electricity |

3. Applications

Pyrolysis: Used for energy recovery and chemical recycling. It is ideal for organic waste with high energy or material value. DOING each waste pyrolysis equipment can handle scalable equipment (500kg–50 TPD) per day, multiple production lines can also be used to cater to small startups and large plants, making them versatile for diverse waste streams. This method generates high returns, but has high requirements for raw materials.

DOING waste recycling pyrolysis equipment

DOING waste recycling pyrolysis equipment

Combustion: Primarily used for waste volume reduction, energy recovery (incineration for electricity). It is often used for non-recyclable, high-volume waste where material recovery is impractical. This method has no requirements for raw materials and is only for waste treatment, generating no returns.

4. Environmental Impact

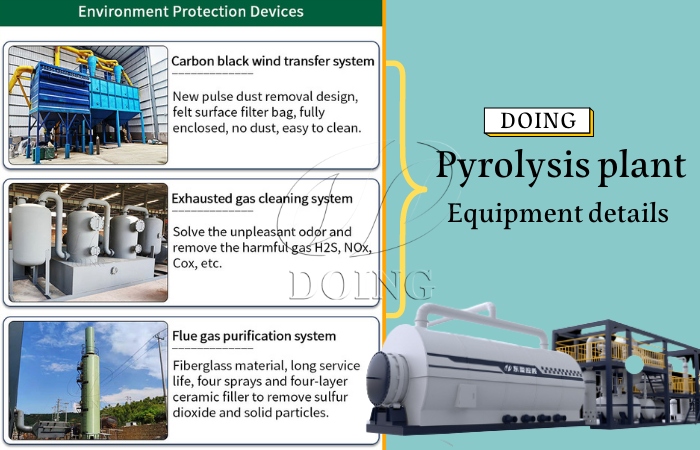

Pyrolysis: Produces fewer air pollutants (NOx, SOx, dioxins) due to oxygen-free conditions, minimizing the formation of toxic compounds like dioxins (common in incomplete combustion). DOING pyrolysis equipment includes a multi-stage purification device (exhaust gas purification device, flue gas purification device), which can remove 99% of pollutants and meet the emission standards of various countries. The reuse of synthesis gas also reduces dependence on fossil fuels, thereby reducing the carbon footprint.

DOING waste pyrolysis equipment environmental system

DOING waste pyrolysis equipment environmental system

Combustion: Emits significant greenhouse gases (CO₂) and potential pollutants (e.g., sulfur oxides, nitrogen oxides, dioxins) if not strictly controlled. It requires expensive scrubbing systems to meet emissions standards, increasing operational costs.

5. Economics Impact

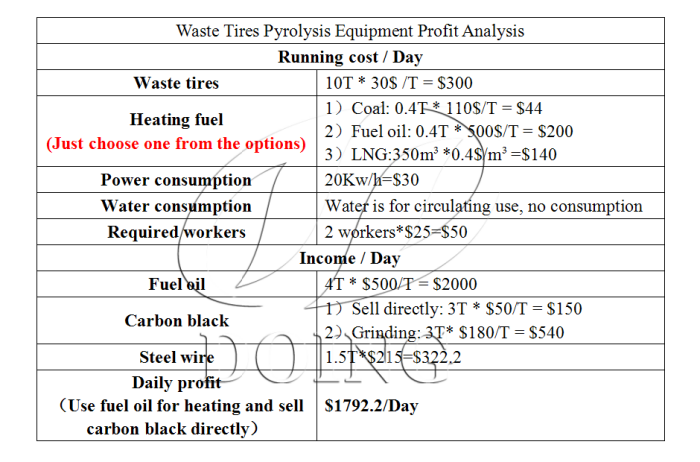

Pyrolysis: Creates tangible, marketable products (oil, carbon black) with stable demand. This is a profit analysis table prepared by Dongying after market research for your reference:

DOING waste pyrolysis profits analysis

DOING waste pyrolysis profits analysis

Combustion: Profits primarily from energy sales (heat/electricity), but revenue is limited by fluctuating energy prices. High operational costs (fuel for combustion, emissions control) often reduce margins.

In conclusion, pyrolysis is a more eco-friendly, energy-efficient, and economically beneficial option for waste treatment compared to combustion. Henan Doing Environmental Protection Technology Co., Ltd, which is a comprehensive environmental pyrolysis equipment manufacturer integrating technological design, research and development, equipment production, sales and after-sales service in one. Would you like a more detailed breakdown? Just feel free to contact us for more information.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.