Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

News

-

DOING News

-

Industry News

Product

Project Case

-

DOING® Group|100 TPD Continuous Tire Pyrolysis Plants Installed for Repeat Client in China

-

Customized 1 Ton/Day Continuous Plastic Pyrolysis System Delivered for Korean Client

-

DOING DY-15 Waste Tire Pyrolysis Machine Project Successfully Installed in Kenya

-

DOING 45,000 Tons/Year Waste Plastic Pyrolysis Project in Vietnam Successfully Commissioned

-

DOING Tire & Plastic Pyrolysis Distillation Plant Successfully Installed in Fiji

-

DOING 50TPD Continuous Oil Sludge Pyrolysis Production Line Successfully Installed in China

-

DOING Installed 15-Ton Tank Bottom Sludge Pyrolysis Equipment for Colombian Repeat Client

-

DOING 30TPD Mazut Oil Distillation Plant Successfully Installed in Kazakhstan

-

-

DOING Three 15-ton Batch Tire Pyrolysis Units in Myanmar On-site Installation Experience

Polish customers ordered 2 sets of 50TPD automatic rubber powder pyrolysis machine

2025-09-09 / DOING News / Leave Message / Chat Online

In August 2025, a Polish renewable-energy company signed a contract with DOING for 2 sets of 50 TPD automatic rubber powder pyrolysis machine. This transaction was completed only four months after the first online consultation, demonstrating the Polish customer's trust in DOING mature and continuous pyrolysis technology and professional services.

This Polish customer, long committed to sustainable development, was now looking to expand into a new business: rubber recycling. They viewed pyrolysis as a way to convert waste rubber powder into valuable fuel oil that could be sold at a profit.

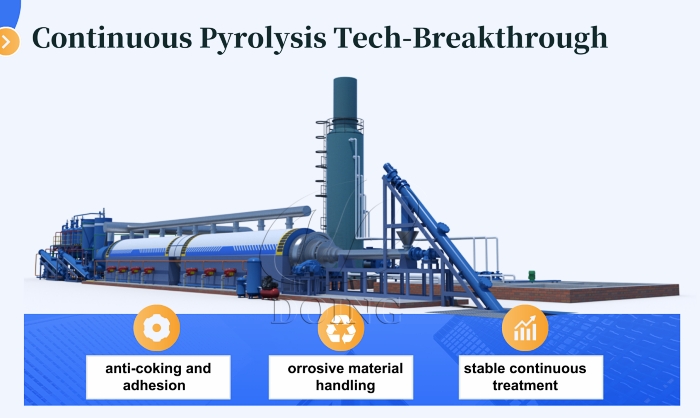

DOING automatic rubber powder pyrolysis machine

DOING automatic rubber powder pyrolysis machine

However, they faced two key challenges:

1. Machine Reliability: Their previous second-hand automatic pyrolysis machine couldn’t maintain stable operation, leading to production halts and financial losses. Thus, they demanded 100% automatic running capability (24/7 operation without frequent downtime).

2. Supplier Expertise: They needed a supplier with proven technical maturity (to avoid operational risks) and professional communication (to address their specific process needs for rubber powder).

DOING automatic rubber powder pyrolysis machine cases

DOING automatic rubber powder pyrolysis machine cases

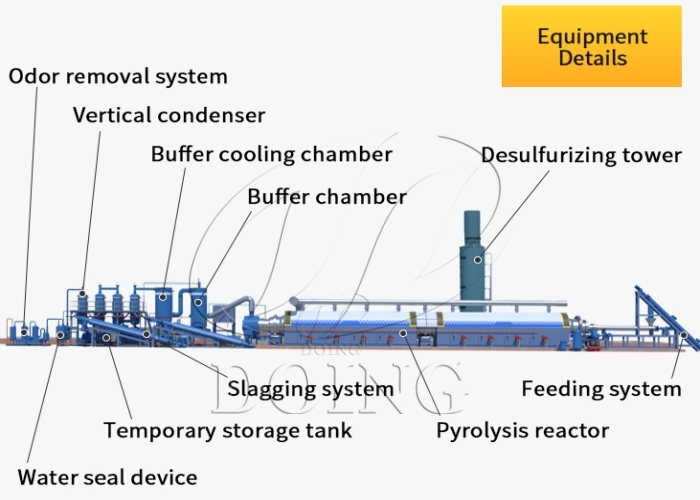

In April 2025, they found DOING via our official website and sent an inquiry, hoping to find a reliable solution. The DOING team responded quickly to customer inquiries, and the entire collaboration process was efficient and transparent. Our sales manager deeply understood the customer's needs and shared DOING over 14 years of experience in automatic pyrolysis machine. We highlighted the core advantages of our 50 TPD automatic rubber powder pyrolysis machine: the entire production line operates continuously, unconstrained by storage silo space, and requires no frequent shutdowns, machine restarts, cooling, or reheating. It can operate uninterrupted for approximately 30-40 days. We also provided case studies from customers in China, the United States, Russia, India, Brazil, Egypt, and Ukraine, demonstrating the machine's reliability.

DOING automatic rubber powder pyrolysis machine details

DOING automatic rubber powder pyrolysis machine details

In August 2025, a Polish customer visited the DOING factory and was impressed by our 40,000-square-meter facility equipped with standardized production lines to ensure consistent machine quality. They expressed satisfaction with DOING technical strength, scale, and service attitude, and immediately placed an order for 2 sets of 50TPD automatic rubber powder pyrolysis machine.

This order not only expands DOING presence in the global rubber powder recycling market but also helps the Polish customer achieve their dual goals of environmental protection and profit. If you're interested in profitably recycling rubber powder, please don't hesitate to contact us.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.