News

News

With the rapid development of the industrial sector, the amount of used oil generated has been increasing year by year. Used oil, if not properly treated, can cause severe environmental pollution. However, through advanced refining technologies, used oil can be transformed into valuable diesel. This not only achieves resource recycling but also reduces environmental burdens. Below, we introduce the chemicals commonly used in the process of refining used oil into diesel and the associated technologies.

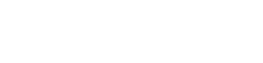

DOING Traditional type and new type used oil refining plant

Traditional acid-base washing technology mainly uses acidic liquid and alkaline liquid as key chemicals.

Acidic liquid: Acidic liquid plays a vital role in the oil refining process. It can neutralize the alkali in the waste oil and react with impurities such as organic acids and resins to generate precipitates, which can be removed by sedimentation separation.

Alkaline liquid: After the acidic liquid treatment, the residual acid is neutralized with alkaline liquid to remove the acidic substances in the oil.

Used oil traditional acid-base washing technology

New solid catalyst distillation technology represents a significant advancement in the field of used oil refining. Compared with the use of acid-base related chemicals to refine waste oil into diesel, solid catalysts are more suitable for investors who are not easy to purchase chemical solutions and have higher requirements for automation.

Types of Solid Catalysts: The solid catalysts used by different merchants may be different. When designing the used oil to diesel refining process, the engineering team of Henan DOING took into account the durability, purification efficiency, refining effect and cost-effectiveness of the solid catalyst, and finally determined the combination ratio of catalyst A and catalyst B. Each ton of catalyst can be used for almost half a year without frequent replacement.

Principles of Solid Catalysts: Solid catalysts function by adsorbing impurities in the used oil onto their surfaces. Under specific temperature and pressure conditions, the catalysts activate the adsorbed impurities and induce chemical reactions. For example, impurities such as polycyclic aromatic hydrocarbons and nitrogen-containing compounds in the oil undergo cracking and hydrogenation reactions on the catalyst surface, breaking down into lighter hydrocarbons and other substances. These substances are then separated and collected through subsequent distillation processes. This achieves the refining of used oil into diesel.

Used oil new solid catalyst distillation technology

When planning to establish a used oil refining plant, selecting the appropriate technology is critical. Traditional acid-alkali washing technology is relatively mature and widely applied, and the investment cost is relatively small. However, the overall oil and acid-base solution neutralization reaction time using this technology is relatively long, and the labor investment cost is high. New solid catalyst distillation technology, while offering higher refining efficiency and better product quality, requires significant investment in equipment and catalyst costs. Generally speaking, it is more cost-effective for used oil to diesel recycling and refining projects with a daily processing capacity of more than 5 tons. Additionally, catalyst regeneration and replacement must be considered. Therefore, enterprises should choose the right technology based on their actual circumstances, such as used oil quality, production scale, and environmental requirements, and ensure strict environmental compliance to achieve sustainable development.

DOING different types of used oil refining to diesel plant

In summary, refining used oil into diesel involves the use of various chemicals, with traditional acid-alkali washing and new solid catalyst distillation being two common technologies. By reasonably selecting and applying these technologies, used oil can be effectively transformed into high-quality diesel, creating economic benefits while protecting the environment.

DOING used oil to diesel refinery plant manufacturer

DOING company specializes in manufacturing used oil to diesel refining plants. With years of technical expertise and practical experience, we can provide customers with high-quality equipment and comprehensive technical solutions. If you'd like a sample flow diagram, equipment list or more information, please feel free to contact us.

Contact DOING experts and learrn how we can service your needs.