Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

News

-

DOING News

-

Industry News

Product

Project Case

-

DOING® Group|100 TPD Continuous Tire Pyrolysis Plants Installed for Repeat Client in China

-

Customized 1 Ton/Day Continuous Plastic Pyrolysis System Delivered for Korean Client

-

DOING DY-15 Waste Tire Pyrolysis Machine Project Successfully Installed in Kenya

-

DOING 45,000 Tons/Year Waste Plastic Pyrolysis Project in Vietnam Successfully Commissioned

-

DOING Tire & Plastic Pyrolysis Distillation Plant Successfully Installed in Fiji

-

DOING 50TPD Continuous Oil Sludge Pyrolysis Production Line Successfully Installed in China

-

DOING Installed 15-Ton Tank Bottom Sludge Pyrolysis Equipment for Colombian Repeat Client

-

DOING 30TPD Mazut Oil Distillation Plant Successfully Installed in Kazakhstan

-

-

DOING Three 15-ton Batch Tire Pyrolysis Units in Myanmar On-site Installation Experience

How to Improve Pyrolysis Processing Efficiency: The Shift from Batch to Continuous Systems

2025-11-13 / Industry News / Leave Message / Chat Online

For businesses in waste-to-fuel recycling, pyrolysis processing efficiency directly impacts profits and operational sustainability. A fundamental strategy to dramatically improve pyrolysis processing efficiency is the shift from traditional batch reactors to semi-continuous and fully continuous pyrolysis systems. This shift addresses key bottlenecks of traditional batch setups and unlocks consistent, high-volume production—with DOING waste pyrolysis systems leading the way in reliable continuous operation.

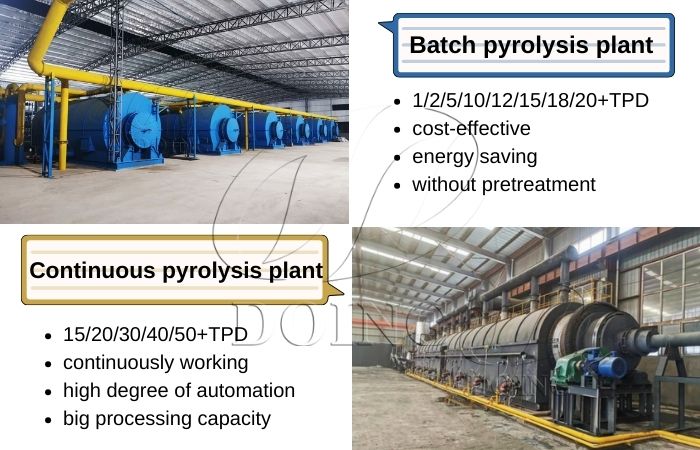

DOING batch continuous pyrolysis system

DOING batch continuous pyrolysis system

Limitations of Batch Pyrolysis System

Batch pyrolysis systems are commonly used in many industries due to their simplicity and lower initial investment cost. However, batch pyrolysis systems have several limitations that hinder their overall efficiency:

1.Low Efficiency: Batch pyrolysis systems process materials in discrete cycles, meaning the machine must stop, cool down, and be reloaded between each batch. This results in significant downtime, reducing pyrolysis system efficiency.

2.High Labor Cost: Batch pyrolysis systems generally require more manual intervention, resulting in higher labor costs and potentially increasing the probability of human error.

DOING batch pyrolysis system details

DOING batch pyrolysis system details

3.Higher Energy Consumption: Compared to traditional waste treatment methods such as landfill and incineration, batch pyrolysis system consumes less energy and emits less carbon. However, compared to continuous operation, the batch operation of pyrolysis systems, such as repeated heating and cooling cycles, consumes relatively more energy.

4.Limited Capacity: Batch pyrolysis systems typically have limited processing capacity, about 5-15 ton per set. It restricts the scalability of waste treatment project, especially when companies seek big or industrial scale pyrolysis systems to increase output.

Efficiency Improvement Solution---Fully Continuous Pyrolysis Systems

Given these limitations, businesses are increasingly looking for ways to shift to pyrolysis systems that can offer higher efficiency and consistency. And continuous pyrolysis systems is an effective solution to improve pyrolysis processing efficiency.DOING continuous pyrolysis systems solve these issues by enabling non-stop feeding, pyrolysis reaction, and product discharge. Their core advantages include:

1.Stable High Output: DOING continuous pyrolysis systems can operate 24/7 without interruption and features intelligent control over the feed rate, heating temperature, and pyrolysis time of the pyrolysis material, improving processing speed and output. This makes it an ideal choice for large-scale waste-to-fuel operations.

2.Improved Energy Efficiency: By maintaining consistent temperatures, continuous pyrolysis systems use energy more effectively, leading to cost savings over time.

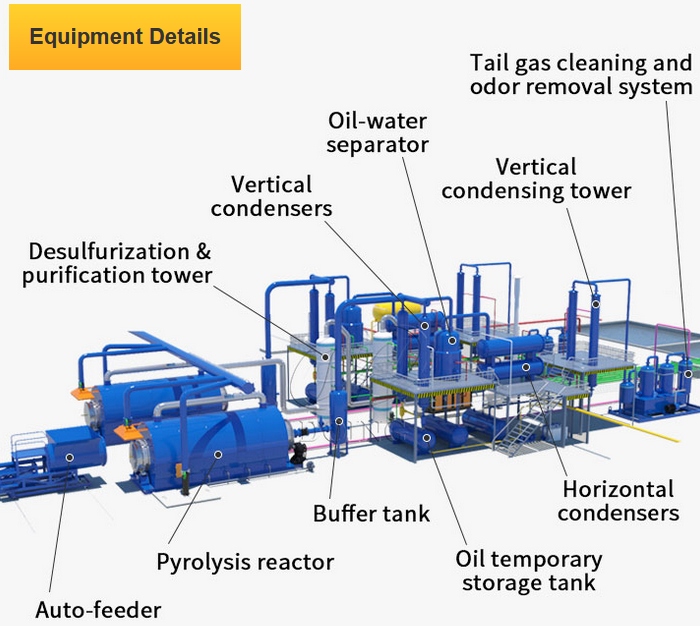

DOING continuous pyrolysis system details

DOING continuous pyrolysis system details

3.Reduced Downtime: DOING continuous pyrolysis systems automate material feeding and discharging, operate around the clock with minimal maintenance interruptions, and can achieve continuous operation from several days to several weeks, (about 45 days---a technicial highlight of DOING continuous pyrolysis technology), thereby improving reliability and efficiency.

4.More Consistent Product Quality: With stable operating conditions, DOING continuous pyrolysis systems produce more uniform output of fuel oil and RCB (recovered carbon black), ensuring a higher quality of fuel.

5.Better Heat Recovery: DOING continuous pyrolysis systems can recover heat from the exhaust products and use it to preheat incoming feedstock, further improving energy efficiency.

Middle Efficiency Improvement Solution---Semi-Continuous Pyrolysis Systems

For some businesses who wants to improve pyrolysis efficiency but don't have enough investment budget for fully continuous pyrolysis systems, semi-continuous pyrolysis systems offer a middle ground. DOING semi-continuous pyrolysis systems combine continuous feeding with batch solid discharge, but unlike batch low-temperature slag discharge, semi-continuous pyrolysis system can directly discharge slag at high temperatures, significantly improving processing efficiency, especially suitable for small and medium-sized enterprises.

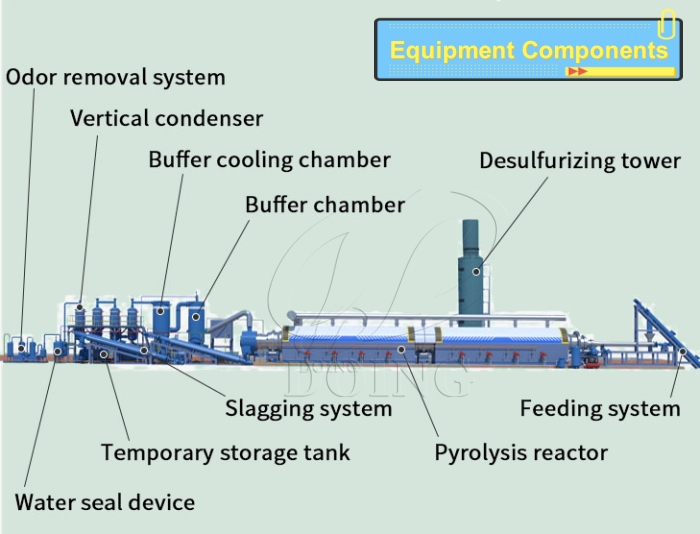

DOING semi continuous pyrolysis systems

DOING semi continuous pyrolysis systems

In summary, shifting from batch to semi-continuous or fully continuous pyrolysis systems, minimizing downtime, saving energy, and boosting automation, is a practical way to improve pyrolysis processing efficiency. DOING pyrolysis system match different business scales, delivering steady performance and cost savings—helping turn waste into reliable profits.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.