Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

News

-

DOING News

-

Industry News

Product

Project Case

-

DOING® Group|100 TPD Continuous Tire Pyrolysis Plants Installed for Repeat Client in China

-

Customized 1 Ton/Day Continuous Plastic Pyrolysis System Delivered for Korean Client

-

DOING DY-15 Waste Tire Pyrolysis Machine Project Successfully Installed in Kenya

-

DOING 45,000 Tons/Year Waste Plastic Pyrolysis Project in Vietnam Successfully Commissioned

-

DOING Tire & Plastic Pyrolysis Distillation Plant Successfully Installed in Fiji

-

DOING 50TPD Continuous Oil Sludge Pyrolysis Production Line Successfully Installed in China

-

DOING Installed 15-Ton Tank Bottom Sludge Pyrolysis Equipment for Colombian Repeat Client

-

DOING 30TPD Mazut Oil Distillation Plant Successfully Installed in Kazakhstan

-

-

DOING Three 15-ton Batch Tire Pyrolysis Units in Myanmar On-site Installation Experience

Which new technologies are helping improve waste pyrolysis oil systems?

2025-12-09 / Industry News / Leave Message / Chat Online

To address the increasingly severe challenges of waste disposal and tap into its resource potential, pyrolysis technology for organic waste such as waste plastics and waste tires is receiving widespread attention. However, traditional waste pyrolysis oil systems and their produced primary pyrolysis oil often face bottlenecks such as unstable oil quality and limited application value.

To fully understand how waste pyrolysis oil systems are being improved, we can examine these advancements in two key areas: improvements to the pyrolysis system itself and the crucial refining of the pyrolysis oil product.

Part 1: Enhancements to the Pyrolysis System Itself

The efficiency, stability, and initial quality of the pyrolysis oil are fundamentally determined by the upstream processing.

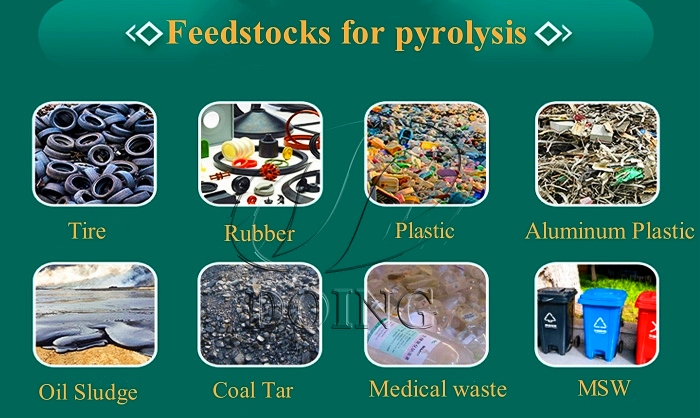

Advanced Pre-Treatment and Feedstock Preparation: The quality and consistency of raw materials have a significant impact on the efficiency and yield of pyrolysis processes. Complex waste often contains high moisture content and various mixed waste materials, which can lead to unstable pyrolysis reactions, reduced oil yield, and increased by-product content. Employing advanced sorting, crushing, and drying technologies to remove contaminants, reduce waste size, and remove moisture from waste materials prepares them for uniform heating.

DOING pyrolysis system pre-treatment devices

Process Control and Reactor Design Innovations: The reactor is the heart of the pyrolysis process, and ongoing design and control improvements are key to maximizing efficiency.

DOING's pyrolysis technology innovation is mainly reflected in three aspects:

1. More sophisticated selection of equipment materials and advanced equipment design and manufacturing techniques result in better heat transfer and insulation performance of the pyrolysis equipment, more efficient raw material pyrolysis processes, more stable operation, energy savings, and a longer lifespan.

Feedstocks of pyrolysis system

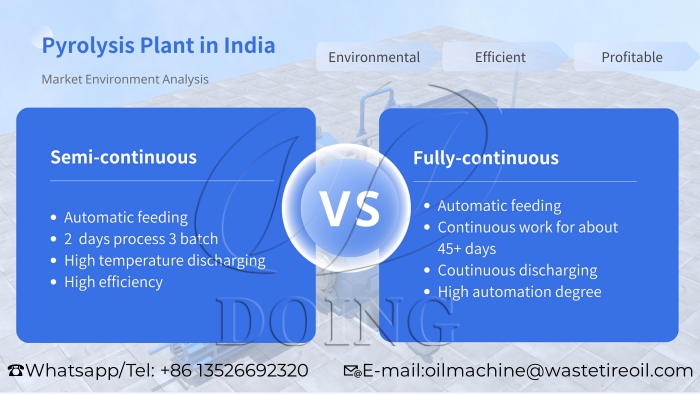

2. Upgrades in equipment technology from batch to semi-continuous and fully continuous pyrolysis systems, diversifying equipment operation modes and processing scale options, and increasing automation levels.

DOING semi-continuous and fully continuouspyrolysis oil production system

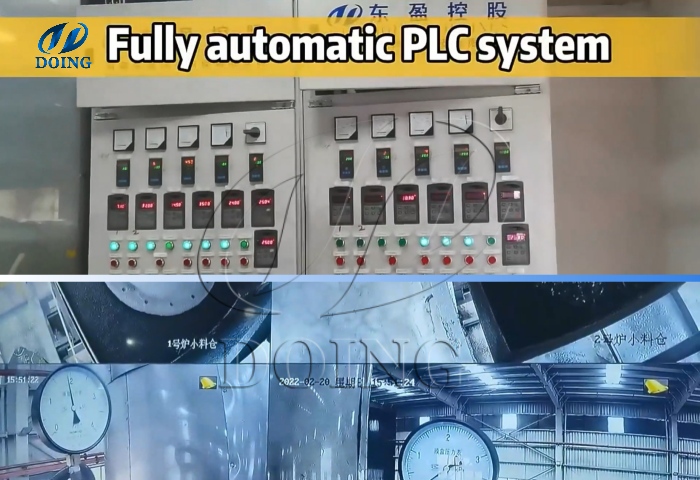

3. Intelligent operation control and monitoring of the pyrolysis system.

DOING pyrolysis system PLC system

The evolution from traditional stoves to continuous, advanced reactor configurations ensures superior heat and mass transfer, leading to more complete and controlled decomposition. Real-time monitoring and automated PLC control systems maintain optimal temperatures and pressures, minimizing undesirable by-products and maximizing oil generation.

Catalysis and decoking: For certain raw materials, particularly certain types of plastics, standard pyrolysis may produce pyrolysis oil containing high concentrations of paraffin, which can lead to solidification problems. Furthermore, the management of coke and other residues within the reactor is crucial. Therefore, catalysts can be introduced during pyrolysis to aid in the decomposition of harmful long-chain hydrocarbons and reduce the formation of heavy compounds. For specialized applications, such as the processing of certain plastics, DOING's pyrolysis systems also integrate highly efficient coke removal systems, ensuring smoother operation and longer equipment life by preventing coking and maintaining efficient heat transfer.

Part 2: Role of Pyrolysis Oil Refining – Turning Waste Oil into Valuable Pyrolysis Diesel

Raw pyrolysis oil, even after initial treatment, typically contains a complex mixture of hydrocarbons and potential impurities. Its properties may not meet the stringent standards required for widespread commercial applications as fuel or chemical feedstock. This limits its direct marketability and economic potential.

The Solution: Pyrolysis Oil Refining System

Brief Process Overview:

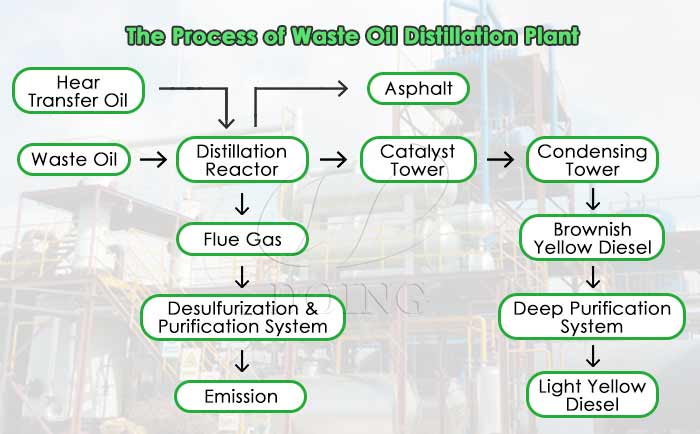

Distillation Fractions: The pyrolysis oil refining system employs advanced distillation technology. The raw pyrolysis oil is heated under controlled conditions to vaporize, and then condensed within a specific temperature range. This process separates the oil into different fractions.

Impurity Removal: Through processes such as dehydration, deacidification, solid catalysis, and decolorization, water, organic acids, precipitates, and other contaminants in the pyrolysis oil can be effectively removed.

Superior Performance: Pyrolysis diesel oil exhibits superior combustion characteristics, lower sulfur content, and more stable viscosity and chemical properties compared to pyrolysis oil.

The process of DOING pyrolysis oil refining system

Key Uses of Refined Pyrolysis Oil (Pyrolysis Diesel):

Transportation Fuel: Pyrolysis diesel can be used in large machinery, ships, and other non-standard diesel engines, providing a sustainable alternative to petroleum-based diesel.

Industrial Heating: It can be used as fuel for industrial boilers and furnaces, reducing reliance on fossil fuels in production processes.

Power Generation: Refined pyrolysis diesel can be used in generators to achieve stable power generation.

Furthermore, pyrolysis oil, after refining, yields another byproduct—asphalt. It can be utilized in road building and paving projects, roofing applications, or as fuel for heavy industrial furnaces and kilns.

Applications of DOING pyrolysis oil refining system products

How Refining Equipment Enhances the Pyrolysis System:

The integration of refining capabilities significantly elevates the overall value and performance of the waste pyrolysis oil system by:

Enhancing Product Value: The most significant contribution lies in the substantial increase in the market value of the final product. By converting low-value pyrolysis oil into higher-value pyrolysis diesel, the profitability of the entire waste-to-fuel process is significantly improved.

Expanding Markets: Pyrolysis diesel fuel has a broader market compared to crude pyrolysis oil, which has inconsistent quality and limited applications.

Improving System Feasibility and Sustainability: By opening up market pathways for pyrolysis oil, pyrolysis oil refining makes the entire waste management and renewable fuel production cycle more economically sustainable and environmentally beneficial.

DOING pyrolysis oil production system manufacturer

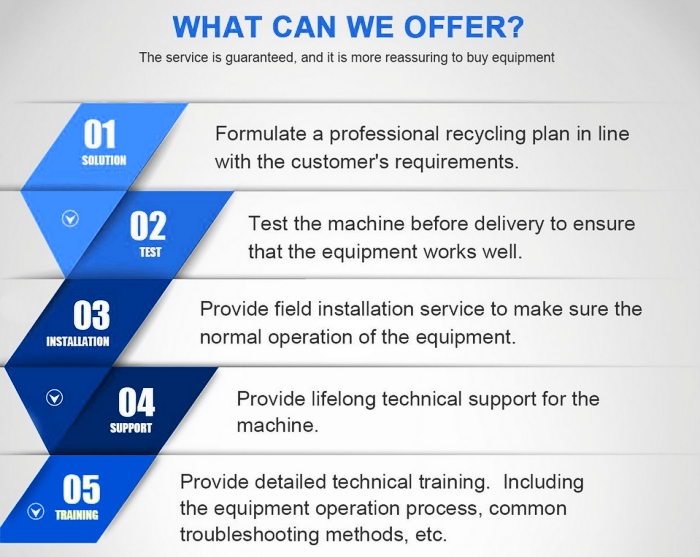

If you are considering improving your waste pyrolysis oil system, or if you are interested in pyrolysis systems or pyrolysis oil refining systems, please contact DOING. We will provide you with the most suitable customized solution based on your specific needs.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.