Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

News

-

DOING News

-

Industry News

Product

Project Case

-

DOING® Group|100 TPD Continuous Tire Pyrolysis Plants Installed for Repeat Client in China

-

Customized 1 Ton/Day Continuous Plastic Pyrolysis System Delivered for Korean Client

-

DOING DY-15 Waste Tire Pyrolysis Machine Project Successfully Installed in Kenya

-

DOING 45,000 Tons/Year Waste Plastic Pyrolysis Project in Vietnam Successfully Commissioned

-

DOING Tire & Plastic Pyrolysis Distillation Plant Successfully Installed in Fiji

-

DOING 50TPD Continuous Oil Sludge Pyrolysis Production Line Successfully Installed in China

-

DOING Installed 15-Ton Tank Bottom Sludge Pyrolysis Equipment for Colombian Repeat Client

-

DOING 30TPD Mazut Oil Distillation Plant Successfully Installed in Kazakhstan

-

-

DOING Three 15-ton Batch Tire Pyrolysis Units in Myanmar On-site Installation Experience

What are the recycling uses of old tires?

2025-11-21 / Industry News / Leave Message / Chat Online

Every year, millions of old tires are discarded globally, posing risks to landfills, exacerbating pollution, and wasting resources. However, these "old" tires hold enormous potential for recycling reuse. Composed primarily of rubber, steel, and synthetic fibers, old tires can be reused in various ways, turning environmental burdens into economic opportunities.

Recycling uses of old tires

Traditional Recycling Uses of Old Tires

1) Crushing into Rubber Particles and Powder:

This is one of the most common recycling methods. After the steel wires are removed from old tires, they are crushed and ground into rubber particles or powder of different sizes. These materials are widely used in:

Rubber Mats: Old tire rubber is made into mats for landscaping, soil and water conservation, and ground safety. These products offer advantages such as shock absorption, weather resistance, and durability. In urban parks, stadiums, and playgrounds, rubber mats made from old tires serve as infill for synthetic running tracks and artificial turf, and as ground safety mats, effectively preventing injuries and offering low maintenance costs.

Road Construction: Crushed or granulated tire rubber is widely used as an additive in asphalt and concrete mixtures. This material, known as rubberized asphalt, improves road durability, reduces cracking, and enhances noise reduction, making it ideal for highways and runways.

Manufacturing: Recycled tires are blended with new materials to produce seals, paving stones, hoses, and even shoe soles, conserving natural rubber resources. Steel wire extracted from tires is melted down to make reinforcing bars and automotive parts, while textile fibers are used to reinforce composite materials.

Fuel: Pre-treated used tires can be used as auxiliary fuel in recycling boilers such as cement kilns and power plants to generate heat.

2) Whole Tire Utilization:

Port Fenders and Crash Barriers: Whole tires are secured to the sides of docks or roads, utilizing their excellent elasticity and wear resistance for cushioning and protection.

Artificial Reefs: These are placed in specific sea areas to provide habitats for marine life.

Civil Engineering: Used as lightweight fill material or as part of drainage layers.

The above methods effectively recycle some old tires, but their processing capacity is limited, the added value of the products is low, and emissions may occur. Next, we will introduce the pyrolysis technology for old tires, a method that enables near-complete value-added utilization of tire components and is increasingly favored by the old tire recycling industry.

Recycling uses of old tires

Recycling Uses of Old Tire Pyrolysis

Tire pyrolysis is a process in which used tires are chemically decomposed by heating them at high temperatures in an oxygen-free environment. During this process, the organic components in the used tires are broken down into valuable products such as gases (syngas), liquids (pyrolysis oil), and solids (carbon black), while the steel wires in the metal bead can be recycled, thus achieving the resource utilization of used tires.

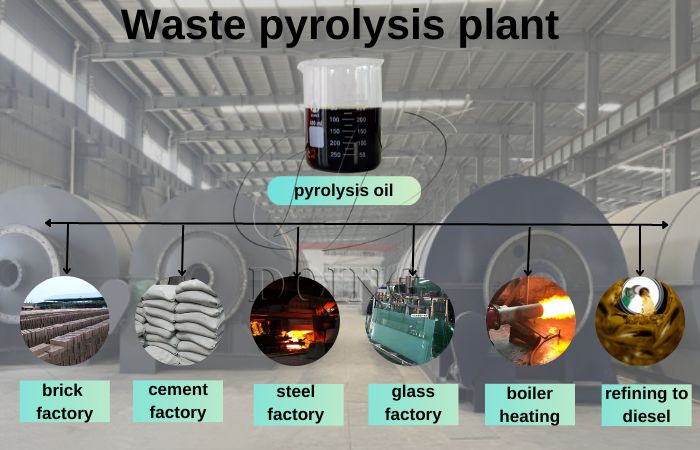

1) Pyrolysis Oil

It has a high calorific value, typically between 40-45 MJ/kg, close to that of heavy oil. The market price is $350-500/ton.

Energy Fuel: It can be used directly as fuel in recycling boilers, steel mills, and power plants, replacing diesel or heavy oil and providing stable heat energy.

Refining and Processing: After further refining, pyrolysis oil can be converted into diesel fuel, a substitute for fuel oil in ships and large machinery.

Applications of old tires pyrolysis oil

2) Carbon Black

Pyrolysis carbon black, also known as recycled carbon black (rCB), is generally cheaper than virgin carbon black, but its applications are becoming increasingly widespread. The market price is between $150-400 per ton. After further processing (such as granulation and purification), the price can increase significantly.

Rubber industry: Carbon black is the most important reinforcing agent in rubber products, significantly improving the tensile strength, abrasion resistance, tear strength, and service life of rubber. It is widely used in the manufacture of new tires, hoses, belts, seals, shock absorbers, etc.

Pigment: As an excellent black pigment, carbon black is widely used in the ink, coating, plastics, and dye industries, giving products a deep black color and good hiding power.

Old tires pyrolysis carbon black usages

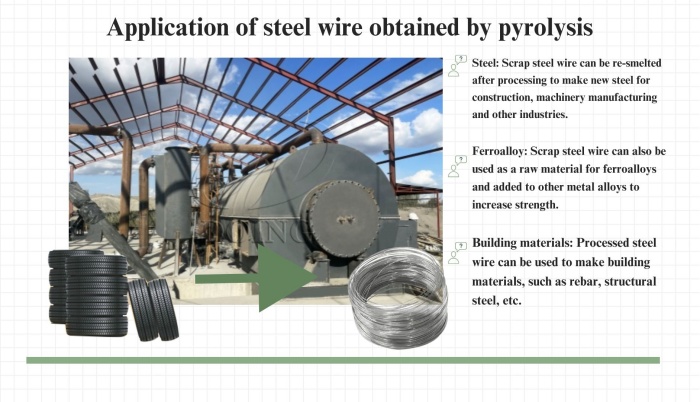

3) Steel Wires

Steel wire is the metal skeleton in tires and has high recycling value. The price mainly fluctuates with the scrap steel market price. The reference range is approximately between $250-400 per ton.

Iron and Steel Smelting: Recycled steel wire is a valuable steel resource that can be directly used in steel mills to produce high-quality steel products, achieving recycling.

Scrap Steel Recycling: Steel wire, as a high-quality scrap steel, has a stable value in the metal recycling market.

Applications of steel wire obtained by pyrolysis

4) Syngas

Non-condensable gases produced during pyrolysis, such as methane (CH₄) and carbon monoxide (CO), contain abundant energy. DOING Company's pyrolysis machines can effectively collect and recycle these gases as a self-sufficient energy source for the pyrolysis reactor. This not only significantly reduces equipment operating energy consumption and improves energy efficiency but also reduces secondary pollution emissions, making the entire pyrolysis process more environmentally friendly.

DOING pyrolysis plant syngas recycling system

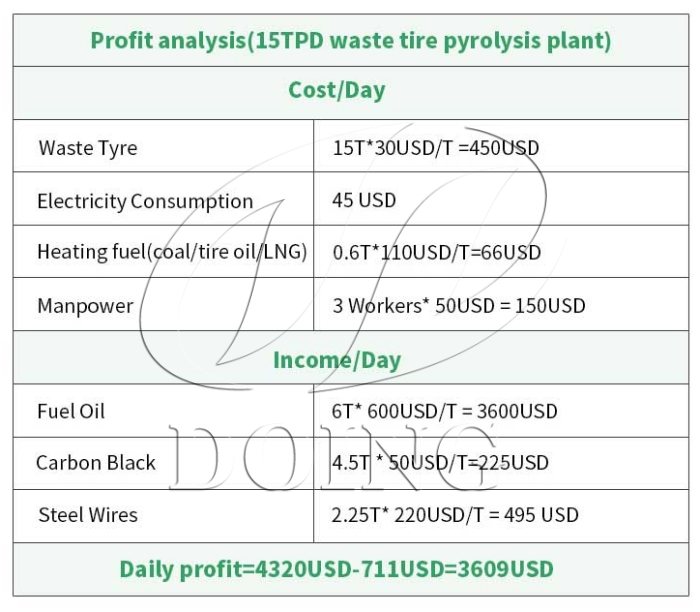

Compared to traditional old tire recycling uses, tire pyrolysis technology exhibits significant advantages:

More Thorough Processing: Traditional crushing only changes the physical state of the rubber itself, while pyrolysis transforms it at the molecular level, converting waste tires almost 100% into three major recycling raw materials: fuel oil, carbon black, and steel wire, with virtually no residual waste.

High Product Value: Pyrolysis not produces low-value-added rubber granules, but fuel oil that can be used directly as energy, carbon black for recycling use, and steel that can be recycled. These products have high market demand and higher value, with applications directly targeting core recycling sectors such as energy, chemicals, and metallurgy.

Profit analysis of old tires pyrolysis plant

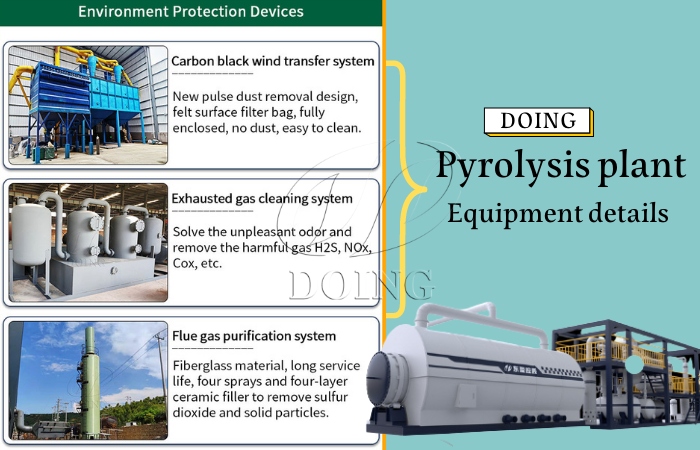

Significant Environmental Benefits: The pyrolysis process takes place in a closed system, effectively preventing the escape of harmful gases. Furthermore, the pyrolysis machine is equipped with a complete set of environmental protection devices, ensuring the whole pyrolysis process environmentally.

DOING old tires pyrolysis plant environment protection devices

Unrestricted by Tire Type: Pyrolysis technology can efficiently process tires of any shape, even those that are heavily contaminated and difficult to sort, offering a wide range of raw material adaptability.

Tire feedstoks of pyrolysis plant

DOING old tires pyrolysis plant manufacturer

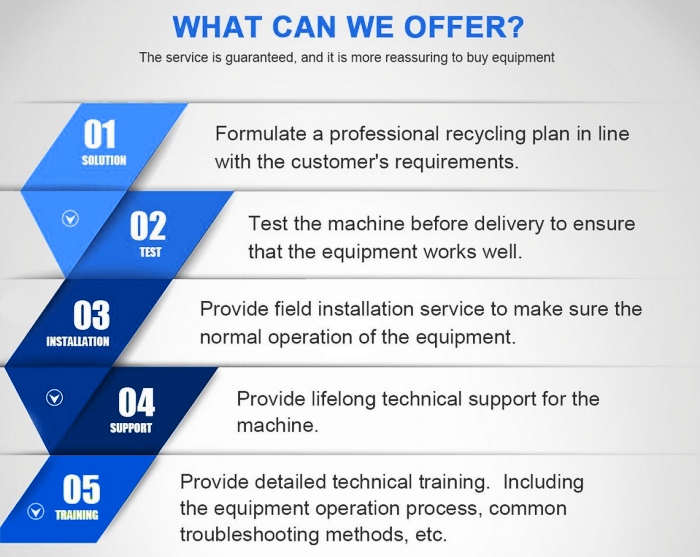

If you are looking for a reliable, efficient, and highly profitable waste tire processing solution, DOING's tire pyrolysis machines are the ideal choice. We provide a full range of services from project consultation, process design, equipment manufacturing to installation and maintenance, dedicated to helping every client successfully launch their pyrolysis business.

Contact us today to learn more about our waste tire pyrolysis technology.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.