Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

Product

Project Case

-

DOING® Group|100 TPD Continuous Tire Pyrolysis Plants Installed for Repeat Client in China

-

Customized 1 Ton/Day Continuous Plastic Pyrolysis System Delivered for Korean Client

-

DOING DY-15 Waste Tire Pyrolysis Machine Project Successfully Installed in Kenya

-

DOING 45,000 Tons/Year Waste Plastic Pyrolysis Project in Vietnam Successfully Commissioned

-

DOING Tire & Plastic Pyrolysis Distillation Plant Successfully Installed in Fiji

-

DOING 50TPD Continuous Oil Sludge Pyrolysis Production Line Successfully Installed in China

-

DOING Installed 15-Ton Tank Bottom Sludge Pyrolysis Equipment for Colombian Repeat Client

-

DOING 30TPD Mazut Oil Distillation Plant Successfully Installed in Kazakhstan

-

-

DOING Three 15-ton Batch Tire Pyrolysis Units in Myanmar On-site Installation Experience

Why we developed the continuous waste tire recycling equipment?

2021-08-26 / Continuous Pyrolysis plant / Leave Message / Chat Online

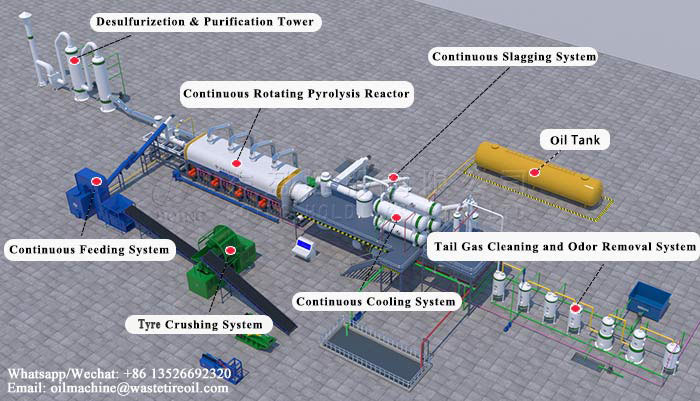

According to the survey, the number of waste tires worldwide is as high as 1.5 billion each year. Facing a huge amount of waste tires, we have developed the continuous waste tire recycling equipment based on the batch waste tire pyrolysis plant. Compared with the previous batch equipment, the continuous waste tire recycling equipment has the following advantages:

Continuous waste tire pyrolysis plant

Continuous waste tire pyrolysis plant

1. Continuous working

Continuous waste tire recycling equipment can keep working 24 hours per day. It adopts automatic sealed feeding and discharging system, which can work simultaneously with high efficiency and high capacity.Therefore, you don't have to wait for cooling before discharging. Meanwhile, you can save the time and fuel for preheating the reactor.

2. PLC automatic control

Continuous waste tire recycling equipment can be controlled by PLC or computer intelligence, which saves manpower and material resources, and makes the whole pyrolysis process more convenient and fast.

3.Unique sealing, internal operation

Continuous waste tire recycling equipment uses an internal rotating drive system that does not require the use of sealing materials, so there is no need to stop frequently to replace the sealing materials in order to achieve true full continuous operation.

4. High oil output rate

Continuous waste tire recycling equipment is multi-reactor continuous operation, the feed is fully cracked. And the connection is installed with a cooling device to ensure safety, The heating source does not directly contact the pyrolysis reactor, which can make the heating uniform and extend the service life of the reactor.

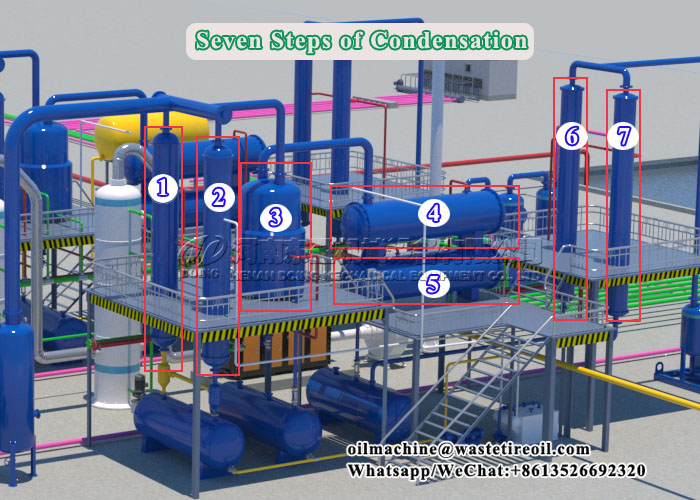

Cooling system

Cooling system

5. Environmental friendly

The non-condensable combustible gas can be used as fuel for heating the reactor after being treated by the exhaust gas purification system. The flue gas generated during the heating of the reactor enters the desulfurization tower and treated to meet the national environmental protection emission standards. The whole process is well sealed to prevent pollution.

If you would like more information about continuous waste tire recycling equipment, please feel free to contact us. Doing company has been engaged in waste tire pyrolysis for about more than 10 years, we are ready to provide valuable information and advice to help you implement the project.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.