Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

Product

Project Case

-

DOING® Group|100 TPD Continuous Tire Pyrolysis Plants Installed for Repeat Client in China

-

Customized 1 Ton/Day Continuous Plastic Pyrolysis System Delivered for Korean Client

-

DOING DY-15 Waste Tire Pyrolysis Machine Project Successfully Installed in Kenya

-

DOING 45,000 Tons/Year Waste Plastic Pyrolysis Project in Vietnam Successfully Commissioned

-

DOING Tire & Plastic Pyrolysis Distillation Plant Successfully Installed in Fiji

-

DOING 50TPD Continuous Oil Sludge Pyrolysis Production Line Successfully Installed in China

-

DOING Installed 15-Ton Tank Bottom Sludge Pyrolysis Equipment for Colombian Repeat Client

-

DOING 30TPD Mazut Oil Distillation Plant Successfully Installed in Kazakhstan

-

-

DOING Three 15-ton Batch Tire Pyrolysis Units in Myanmar On-site Installation Experience

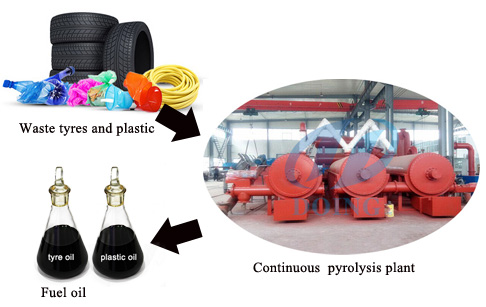

What is difference of batch waste tire pyrolysis plant and continuous waste tire pyrolysis plant

2016-10-29 / Continuous Pyrolysis plant / Leave Message / Chat Online

Batch pyrolysis plant and continuous pyrolysis plant

Both machine have the same working theory but different working process.

Batch waste tire pyrolysis plant:

Batch waste tire pyrolysis plant

People need to put raw material into reactor, then close feeding door.

After Burning the fuel material (coal, wood, natural gas or oil) in the furnace. Reactor will be slowly heated.the reactor need to heat 2 hours, then the raw material start to pyrolysis.

After finishing one turn pyrolysis process, the carbon blank start to discharge.

After cooling the reactor, then people can start the next batch.

Continuous waste tire pyrolysis plant

1.Only need two person operate

2.Can keep feeding at least 20t waste tire in one time pyrolysis process

3.Waste tire Pyrolysis and carbon black discharge occur at the same time

4.Multiple reactors design for fully pyrolysis to get high oil rate

5.PLC computer control system ensure the safty

6.Indirect heating to prolong the usage life of the reactor

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.