Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

News

-

DOING News

-

Industry News

Product

Project Case

-

DOING® Group|100 TPD Continuous Tire Pyrolysis Plants Installed for Repeat Client in China

-

Customized 1 Ton/Day Continuous Plastic Pyrolysis System Delivered for Korean Client

-

DOING DY-15 Waste Tire Pyrolysis Machine Project Successfully Installed in Kenya

-

DOING 45,000 Tons/Year Waste Plastic Pyrolysis Project in Vietnam Successfully Commissioned

-

DOING Tire & Plastic Pyrolysis Distillation Plant Successfully Installed in Fiji

-

DOING 50TPD Continuous Oil Sludge Pyrolysis Production Line Successfully Installed in China

-

DOING Installed 15-Ton Tank Bottom Sludge Pyrolysis Equipment for Colombian Repeat Client

-

DOING 30TPD Mazut Oil Distillation Plant Successfully Installed in Kazakhstan

-

-

DOING Three 15-ton Batch Tire Pyrolysis Units in Myanmar On-site Installation Experience

Opportunities and Development Prospects of Waste Tire Recycling Pyrolysis Business in Sweden

2025-10-09 / Industry News / Leave Message / Chat Online

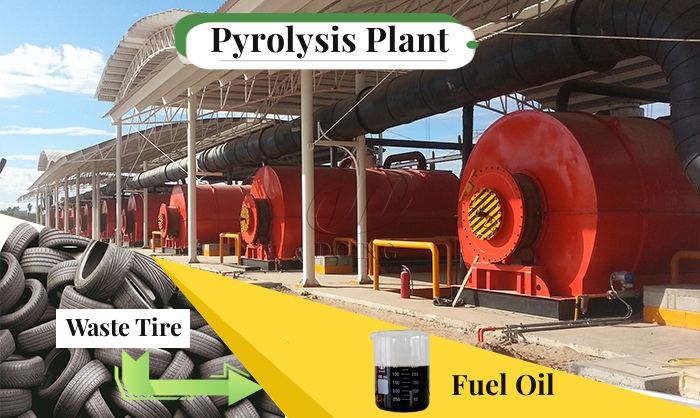

According to the latest news, a large-scale waste tire pyrolysis plant being constructed by an environmental recycling company in Uddevalla, Sweden. This waste rubber tire recycling facility will have the capacity to process 34.5 kilotonnes of end-of-life tires (ELTs) annually. The plant features five advanced tire pyrolysis plant reactors, a critical component in the recycling process, which allows for the extraction of valuable materials such as carbon black, oil, and steel from tires.

Multiple tire recycling pyrolysis reactor lines

Multiple tire recycling pyrolysis reactor lines

The successful implementation of such waste to energy pyrolysis technology showcases the potential for similar projects in Sweden. As businesses in the country look to align with sustainability goals and reduce waste, investing in pyrolysis technology can lead to both environmental benefits and economic opportunities.

Market Demand and Customer Groups

The tire pyrolysis industry's market demand primarily stems from the resource utilization of scrap tires, with a diverse customer base encompassing the following sectors:

①Market Demand

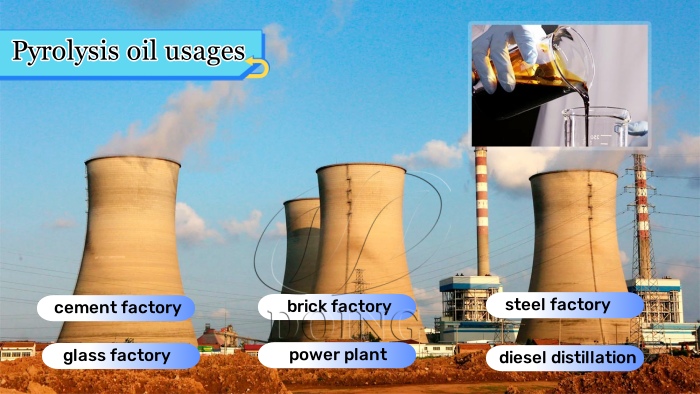

Industrial Fuel: Tire pyrolysis oil TPO/tire derived fuel TDF can be used as fuel in industrial boilers, heavy oil power plants, and other applications. Demand in this sector will reach 36.01% in 2024, and demand for high-calorific-value fuels continues to grow as environmental policies drive growth.

Waste tyre pyrolysis oil sales chanels

Waste tyre pyrolysis oil sales chanelsRubber Recycling: Rubber from scrap tires can be ground into recycled rubber for use in rubber products, alleviating pressure on natural rubber imports.

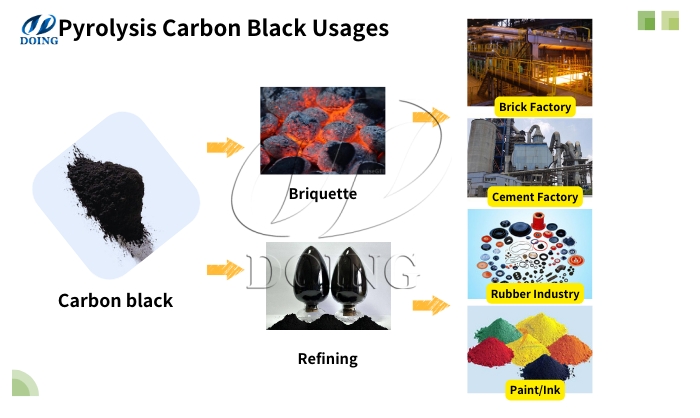

Material Recovery: Carbon black, steel wire, and other materials produced by pyrolysis can be directly used in rubber product production or metalworking, reducing raw material costs.

Waste tyre pyrolysis recovered carbon black usages

Waste tyre pyrolysis recovered carbon black usages

②Customer Groups

Industrial Enterprises: These include power plants, glass manufacturers, and steel smelters, with demand concentrated in the industrial fuel and material recycling sectors.

Rubber Manufacturers: Companies that require recycled rubber to produce tires, rubber tracks, and other products.

Environmental Protection Agencies: Over 3.2 million tonnes of scrap tyres are produced in Sweden every year, only a small proportion of which is recycled. The government is promoting the development of recycling systems through subsidies and tax incentives. With policy support, many environmental protection agencies can initiate tire recycling and pyrolysis projects.

Waste tire recycling for fuel oil

Waste tire recycling for fuel oil

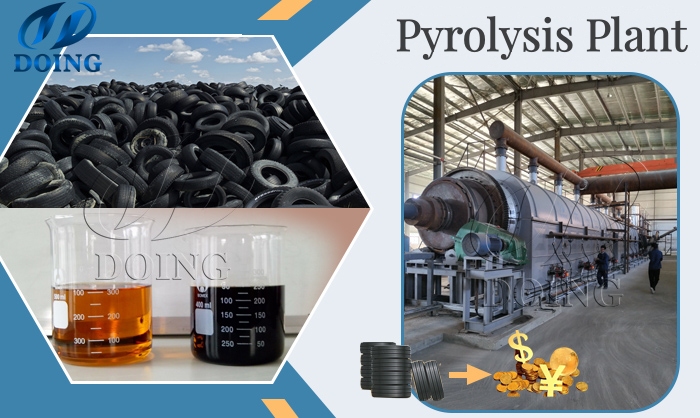

Economic Incentives and Support

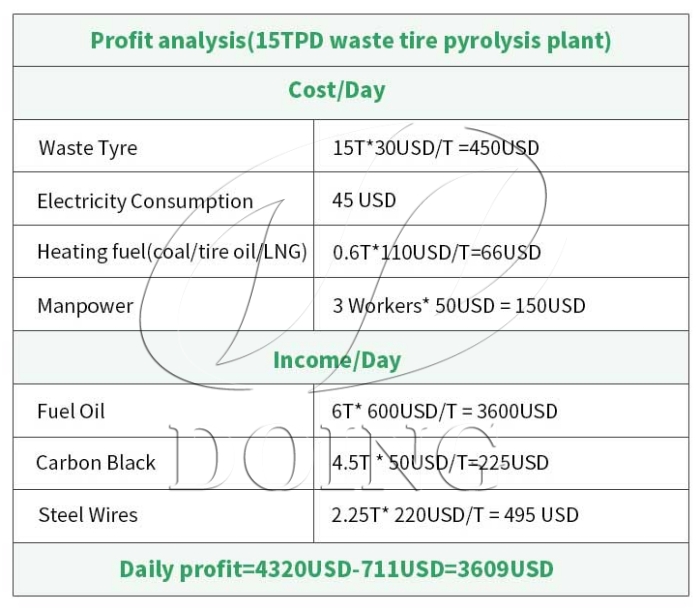

After recycling and pyrolysis of waste rubber tires, selling the reclaimed pyrolysis oil, recovered carbon black, and steel wire can generate substantial profits. A 15-ton tire pyrolysis project is expected to generate monthly profits exceeding US$60,000.

15 ton tire pyrolysis plant profit analysis

15 ton tire pyrolysis plant profit analysis

Besides that, Sweden offers various incentives for companies investing in green technologies, including grants, subsidies, and favorable loan conditions. By tapping into these resources, businesses can mitigate initial investment costs associated with establishing pyrolysis plants.

Additionally, the Swiss government is actively promoting circular economy practices, which emphasize resource efficiency and waste reduction. This supportive regulatory environment creates a favorable landscape for the growth of the tire recycling industry.

Future Prospects of Tire Recycling Pyrolysis Business in Sweden

The future of the waste tire recycling and pyrolysis business in Sweden looks promising. With advancements in technology and growing market demand, companies that invest now can secure a competitive edge. As more businesses recognize the benefits of recycling waste rubber tires, the industry will likely see increased collaboration between manufacturers, waste management firms, and environmental agencies.

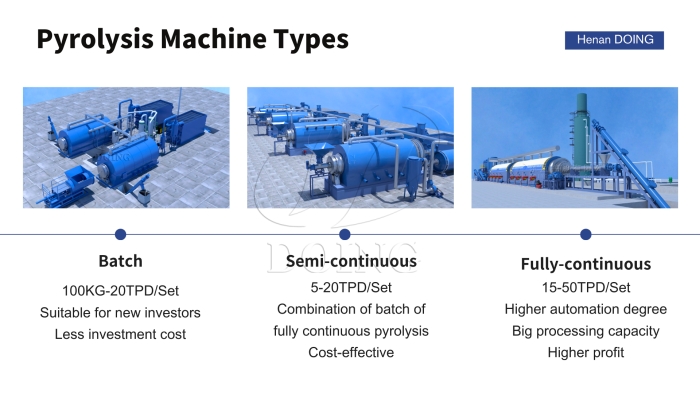

For companies interested in entering this burgeoning market, now is the time to take action. Whether you're an automotive manufacturer looking for sustainable materials or a waste management company seeking innovative solutions, DOING advanced rubber tire recycling pyrolysis machines can meet your needs, from batch type to fully continuous type, from small scale to large industrial scale.

Different types of tire recycling pyrolysis machines for sale

Different types of tire recycling pyrolysis machines for sale

Are you ready to explore the opportunities in the waste tire recycling pyrolysis business? Contact Henan Doing Company today to learn more about our pyrolysis technology and how we can help you set up a sustainable and profitable waste rubber tire pyrolysis plant project in Sweden!

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.