Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

Product

Project Case

-

DOING® Group|100 TPD Continuous Tire Pyrolysis Plants Installed for Repeat Client in China

-

Customized 1 Ton/Day Continuous Plastic Pyrolysis System Delivered for Korean Client

-

DOING DY-15 Waste Tire Pyrolysis Machine Project Successfully Installed in Kenya

-

DOING 45,000 Tons/Year Waste Plastic Pyrolysis Project in Vietnam Successfully Commissioned

-

DOING Tire & Plastic Pyrolysis Distillation Plant Successfully Installed in Fiji

-

DOING 50TPD Continuous Oil Sludge Pyrolysis Production Line Successfully Installed in China

-

DOING Installed 15-Ton Tank Bottom Sludge Pyrolysis Equipment for Colombian Repeat Client

-

DOING 30TPD Mazut Oil Distillation Plant Successfully Installed in Kazakhstan

-

-

DOING Three 15-ton Batch Tire Pyrolysis Units in Myanmar On-site Installation Experience

Safety measures for waste tire/plastic to oil pyrolysis plant

2016-07-12 / Continuous Pyrolysis plant / Leave Message / Chat Online

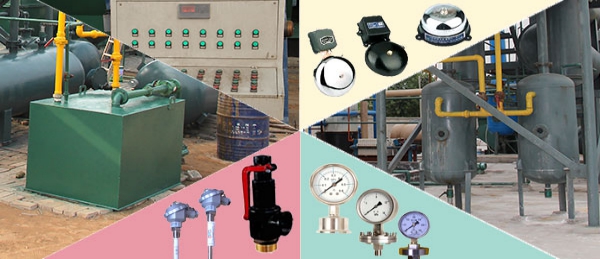

Waste tire/plastic to oil pyrolysis plant safety component

2. We have safety valves, pressure value, thermometers, alarming and other safety devices for waste tire/plastic pyrolysis plant. Once the pressure of the system reach the already set pressure value, alarming will ring, if there is no one besides, pressure valve will open automatically so that waste tire/plastic to oil pyrolysis plant can run safely.

3.Oil-water device. Gas pipe goes under the surface of water, which can prevent the gas reflux to the reactor and avoid blast to ensure waste tire/plastic to oil pyrolysis plant safe running .

4.Water seal device is same with oil-water device for waste tire/plastic to oil pyrolysis plant safe working.

5.Vaccum system. vacuum system is the unique device of our waste tire/plastic to oil pyroysis plant, which can ensure the whole plant operate under a negative pressure, and escape the hazard of high pressure in the inner system.

6.X-ray test. Just now testing the material is the first step, after welding, we will use the X-ray test for testing welding crack line. If there is little leak, we will do again, you know it is very dangerous if there is any little leak during the welding, inside is oil gas, outside is fire, so test the welding is also very important for waste tire/plastic to oil pyrolysis plant.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.