Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

News

-

DOING News

-

Industry News

Product

Project Case

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

-

50TPD fully continuous waste tyre pyrolysis plant installed in Russia

What is the return on investment in a plastic pyrolysis plant?

2023-11-30 / Industry News / Leave Message / Chat Online

A plastic pyrolysis plant is a technology that converts waste plastic into valuable products such as fuel oil, carbon black, and syn-gas. The return on investment in a plastic pyrolysis plant is influenced by several key factors:

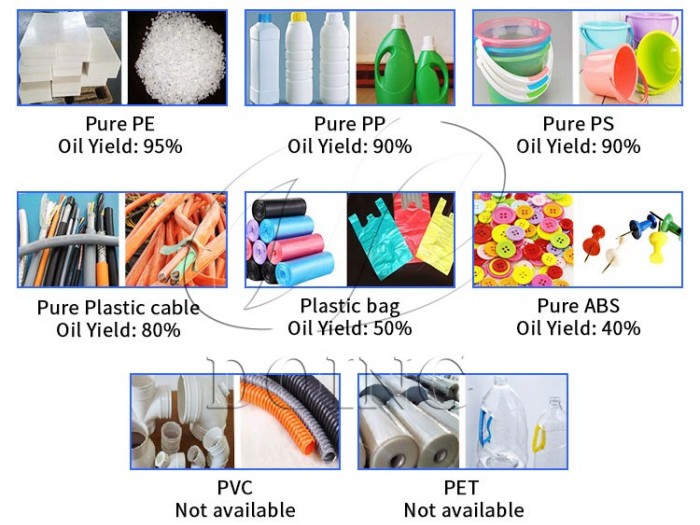

1. Waste plastic Availability: The availability of waste plastic is crucial for the success of a plastic pyrolysis plant. Areas with abundant sources of plastic waste, such as industrial zones or densely populated regions, provide a steady supply of raw materials, ensuring a continuous operation of the plant and maximizing the return on investment. Of course, the purer the plastic, the higher oil output, the higher the return on investment.

Oil output of watse plastics

Oil output of watse plastics

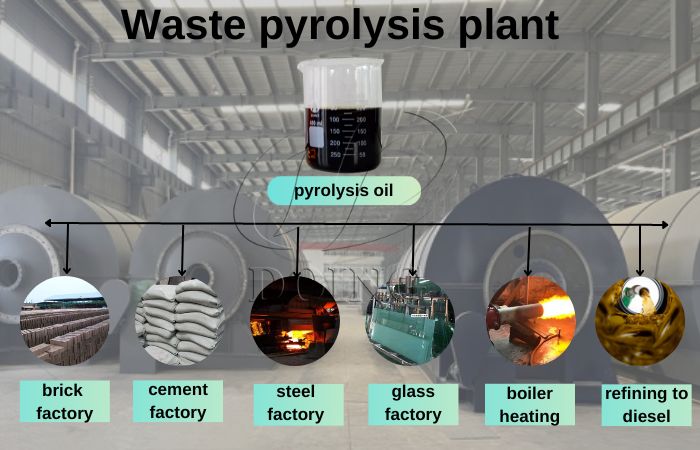

2. End Product Value: The market value of the end products, particularly fuel oil and carbon black, significantly impacts the return on investment in a plastic pyrolysis plant. The fuel oil can be used as alternative fuels in some industries, such as cement factories, steel factories, glass factories, and in heavy oil generators, etc.; the carbon black can be used as heating fuels or be further refined to make new rubber products, like tires, shoes, and used as paints.

Applications of obtained fuel oil

Applications of obtained fuel oil

3. Operating Costs: Managing operating costs is crucial for achieving a favorable return on investment in a plastic pyrolysis plant. Key cost factors include equipment, labor, electricity, maintenance, etc. Employing efficient automation systems, optimizing energy consumption, and implementing preventive maintenance practices can help minimize operational expenses. While considering these factors, DOING plastic pyrolysis plants is a good choice.

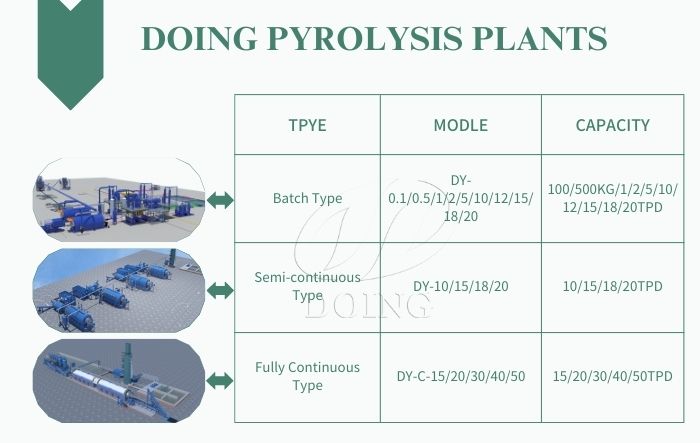

1) DOING has our own manufacturing factory, so we can provide our customers with reasonable prices. We have plastic pyrolysis plants with various types and capacities from 100/500KG per batch to 50+ TPD. With different configurations, the cost will be different. Of course, the better configuration, the higher the price, the better the performance;

Different types and capacities of DOING plastic pyrolysis plant

Different types and capacities of DOING plastic pyrolysis plant

2) DOING plastic pyrolysis plant adopts the best materials and latest technology, such as the automatic PLC control system, which can enhance operation efficiency while ensuring the long service life of machine to save labor cost and maintenance cost;

3) DOING plastic pyrolysis plant can make full use of the by-product-syn gas, which can be used as a supplementary fuel for the plant's heating system, reducing energy costs and increasing overall efficiency; and our plastic pyrolysis plant adopts circulated water, saving water consumption;

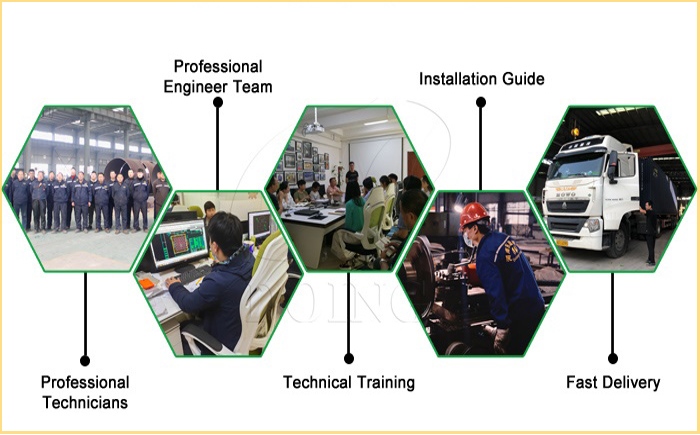

Comprehensive services provided by DOING

Comprehensive services provided by DOING

4) DOING will provide professional installation and operation guidance for our customers, which can help our customers reduce unnecessary operation cost waste as much as possible; and we also provide the one-year guarantee services;

4. Government Incentives: Many governments around the world provide incentives and policies to promote waste management and environmental sustainability. These incentives can include tax credits, grants, subsidies, or favorable regulations. Understanding and utilizing such incentives can significantly enhance the return on investment in a plastic pyrolysis plant.

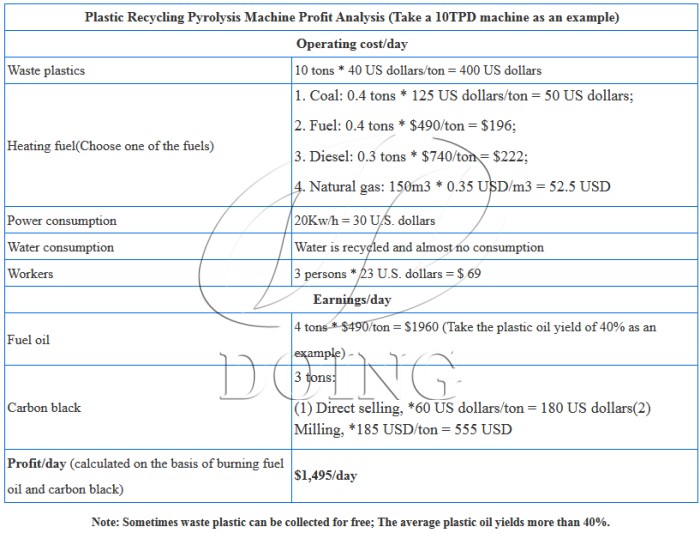

All in all, the return on investment in a plastic pyrolysis machine is considerable. The following is one return analysis of DOING plastic pyrolysis plant based on the market survey and customer feedback:

Return analysis of DOING plastic pyrolysis plant

Return analysis of DOING plastic pyrolysis plant

For more details of the return on investment in a plastic pyrolysis plant or any question, just feel free to leave a message or contact us directly!

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.