News

News

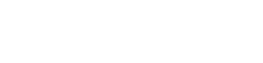

There are mainly two ways for waste plastic recycling, and they are plastic oil recovery and plastic material recovery. Since plastic material recovery is limited to some certain plastics, plastic oil recovery through pyrolysis is a more commonly and popular way for waste plastic recycling, which can be realized by waste plastic pyrolysis plant.

DOING company plastic recycling plant

DOING company plastic recycling plant

Plastic material recovery is mainly through pelleting. Waste plastic should be sorted, cleaned, shredded and pelletized before returning to the production channel at the mixing or manufacturing stage. Only a few plastic is suitable for pelleting, so this way cannot effectively recycle waste plastic.

By contrast, recycling plastic into fuel oil through waste plastic pyrolysis plant will be a better solution of waste plastic recovery and it is also the one with the best economical benefit.

As we know, plastics are usually made up of hydro-carbon polymers. In other words, plastic is made from crude oil extracted from under the ground. Therefore, through processes of heating, pyrolysis, cooling, etc., waste plastic pyrolysis plant can decompose plastic polymers into smaller carbon chains, namely fuel oil.

The application of fuel oil

The application of fuel oil

The obtained fuel oil has wide uses and great values. The fuel oil we get by recycling waste plastics has a high calorific value and is a good fuel for boiler heating, cement plants, steel plants or heavy oil generators, etc. With today's rising oil prices, you can sell fuel directly at a better market price or use fuel oil as a substitute for heavy fuel oil. And you can also further refine the plastic pyrolysis fuel oil into diesel used for industrial heating, vehicles and generators, etc. through distillation plant.

DOING waste pyrolysis plant can efficiently recycle waste plastic into fuel oil, and there is no need to do the selection and cleaning work. The whole process is safe and environmentally friendly. For different processing needs of our customers, we can customize different scales batch waste plastic pyrolysis plants or continuous waste plastic pyrolysis plants! Please don't hesitate to send us your inquiry if you are interested!

Contact DOING experts and learrn how we can service your needs.