DOING New-tech tyre/plastic oil distillation machine is mainly composed of 4 reactors: Respectively for hydration& impurities precipitation, etherification &neutralization, distillation and de-colorization, cooling system, vacuum system, filtering system, boiler heating system as well as de-dusting System.

Chat Online Leave A Message

| Technical parameter of New way waste oil recycling to diesel machine | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

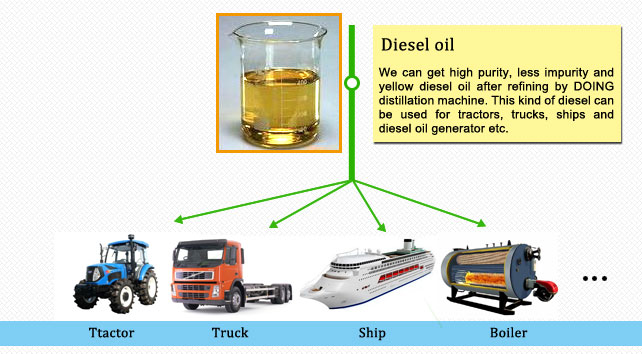

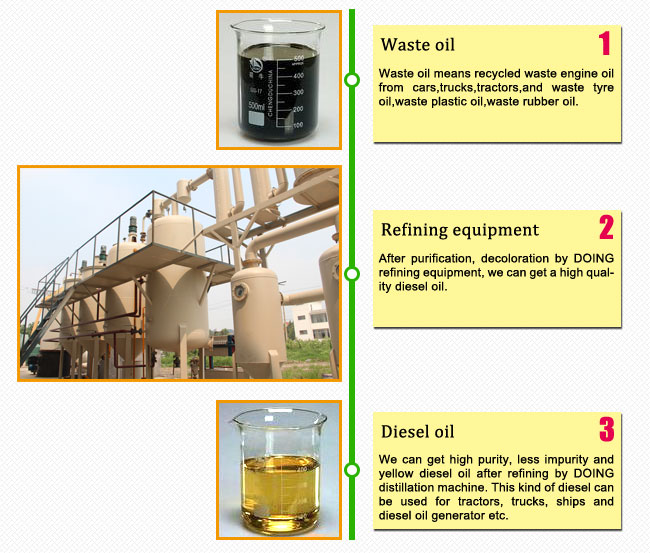

| Raw material | Waste engine oil, tire oil, plastic oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |