High technology environmental waste tire oil pyrolysis plant to fuel oil

High technology environmental waste tire oil pyrolysis plant to fuel oil

Waste tire is often called “black pollution”, because it not only easily causes fire, but also pollutes the environment. However, it is also a kind of valuable renewable resources for human beings. Through the use of waste tire oil pyrolysis plant to fuel oil manufactured by Doing company. We can get three kinds of final products: 45%-52% tyre fuel oil, 30% carbon black, 12%- 15% steel wire and 10% gas . They all have a wide range of applications. For example, the tire fuel oil can be used as industrial fuel materials for burning, or further refined to diesel or gasoline. The carbon black can be used for construction bricks with clay or used as fuel. The steel wire can be re-sale or reprocessing. There is also a little combustible gas producing in the process, the gas can be recycled to heat the reactor as fuel, which will save energy for the whole working process.

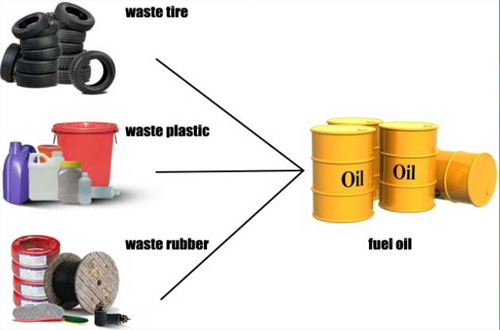

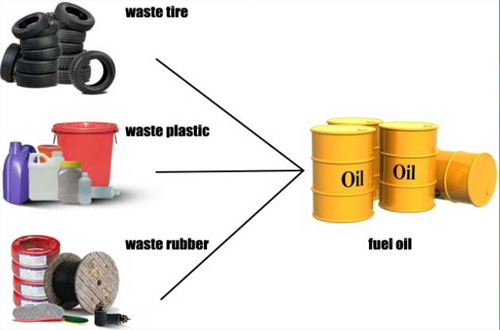

High technology environmental waste tire oil pyrolysis plant to fuel oil raw material

The raw material of high technology environmental waste tire oil pyrolysis plant to fuel oil

1.Waste tire/tyre

2.Waste plastic

3.Waste rubber

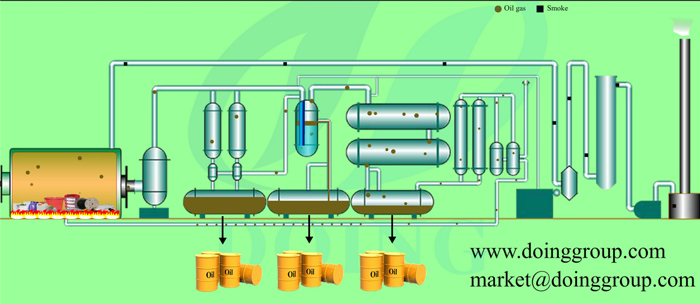

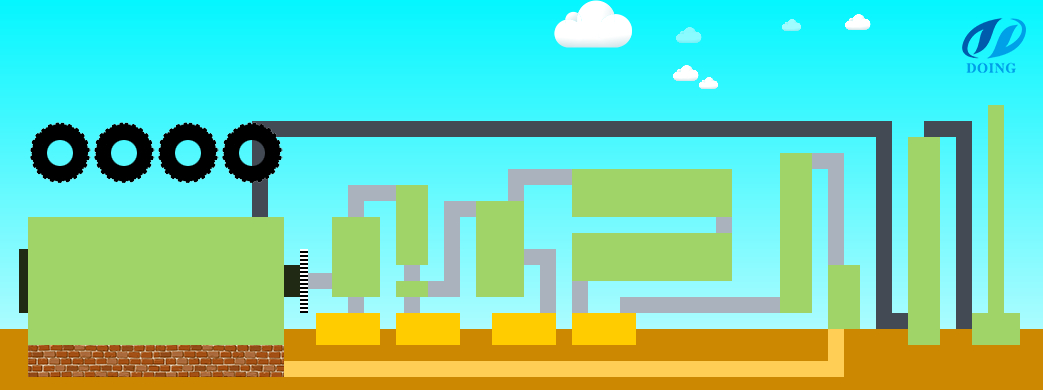

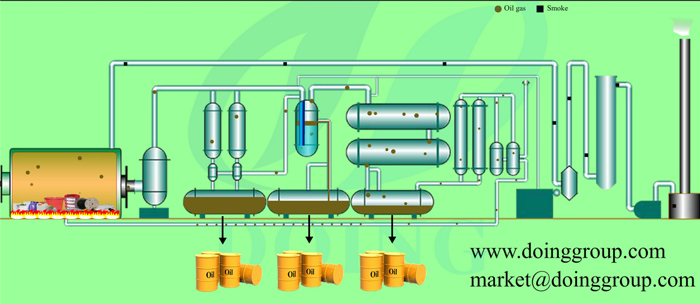

High technology environmental waste tire oil pyrolysis plant to fuel oil working principle

High technology environmental waste tire oil pyrolysis plant to fuel oil is proessing waste tires

1. Firstly, the raw material was put into furnace with auto feeder,then seal the feed inlet system.

2. Secondly, burned the fuel material (coal, or wood, or natural gas, oil ) in the combustion system .The reactor will slowly heat, when the temperature reach around 150 degree Celsius, it will produce oil gas .

3.Oil gas will be processed by our technology ,then gone to cooling system to cold liquid oil. The gas which can not be liquid under normal pressure ,which will be designed to back to combustion system to instead the fuel material to burn the reactor .which can save energy very much.

4. After finished oil produce ,the temperature of reactor will be down ,in same time ,carbon black will be discharged automatically.

5. Lastly, when the temperature fall to 100 degree Celsius, worker could opened the door of reactor to discharge of steel wire .

Then can start to another batch working.

High technology environmental waste tire oil pyrolysis plant to fuel oil main features

High technology environmental waste tire oil pyrolysis plant to fuel oi feature

1.We can get tyre oil,carbon black,and steel from waste rubber tyres and plastics.

2. High oil output rate 45%-52%, the rubber up to 60%.

3. Rapid condenser, we have 5 condensers, the cooling area up to 53 square meters, the area larger, the more oil u can get.

4. Large capacity: 6tons / 8tons / 10tons / 12tons / 20tons.

5. Safety device, we have automatic alarm bells with pressure gauge, If pressure gauge more than the pressure, bells will ring.

6. Environmental protection, no pollution, no smell.

7. 6—8 years life, 1 years warranty

High technology environmental waste tire oil pyrolysis plant to fuel oil technical data

|

Technical parameter of waste tire oil pyrolysis plant to fuel oil |

|

No. |

Items |

Contents |

|

1 |

Equipment type |

DY-1-6 |

DY-1-8 |

DY-1-10 |

|

2 |

Raw material |

Waste tire |

Waste tire |

Waste tire |

|

3 |

Structural form |

Horizontal rotation |

Horizontal rotation |

Horizontal rotation |

|

4 |

24-hour Capacity |

6 ton |

8 ton |

10 ton |

|

5 |

Oil yield |

2.7-3.3ton |

3.6 -4.4ton |

4.5 -5.5ton |

|

6 |

Operating pressure |

Normal |

Normal |

Normal |

|

7 |

Material of pyrolysis Reactor |

Q245R |

Q245R |

Q245R |

|

8 |

Thickness of pyrolysis Reactor |

16mm |

16mm |

16mm |

|

9 |

Rotate speed of pyrolysis Reactor |

0.4turn/minute |

0.4turn/minute |

0.4turn/minute |

|

10 |

Total power |

19KW |

19KW |

19KW |

|

11 |

Mode of cooling |

Water cooling |

Water cooling |

Water cooling |

|

12 |

Cooling area of condenser |

100sqm |

100sqm |

100sqm |

|

13 |

Kind of transmission |

Internal gear drive |

Internal gear drive |

Internal gear drive |

|

14 |

Noise dB(A) |

≤85 |

≤85 |

≤85 |

|

15 |

Size of Reactor(D×L) |

2200×6000 |

2200×6600 |

2600×6600 |

|

16 |

Working form |

Intermittent operation |

Intermittent operation |

Intermittent operation |

|

17 |

Delivery time |

20days |

20days |

20days |

|

18 |

Weight |

27T |

30T |

35T |

|

Prepared by customer about waste tire oil pyrolysis plant to fuel oil |

|

No. |

Item |

Consumption |

|

1 |

Coal(for choice) |

500kg/day |

|

2 |

Wood(for choice) |

800kg/day |

|

3 |

Natural gas(for choice) |

100-150kg/day |

|

4 |

Oil(for choice) |

300-350kg/day |

|

5 |

Electricity |

244kwh/day |

|

6 |

Water(recycled) |

60㎥ /month |

|

7 |

Total power |

19kw |

|

8 |

Land area |

35m*15m |

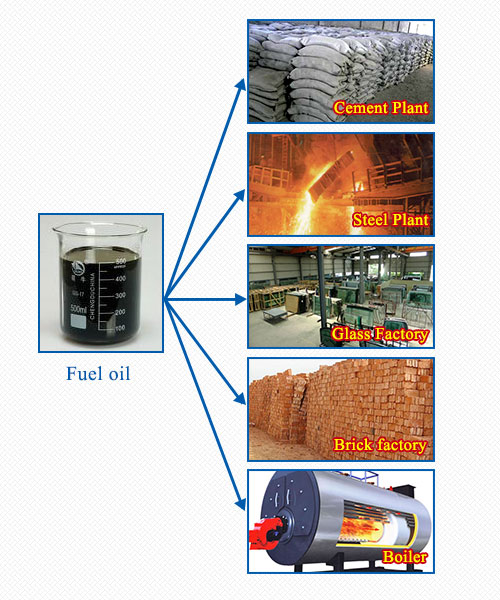

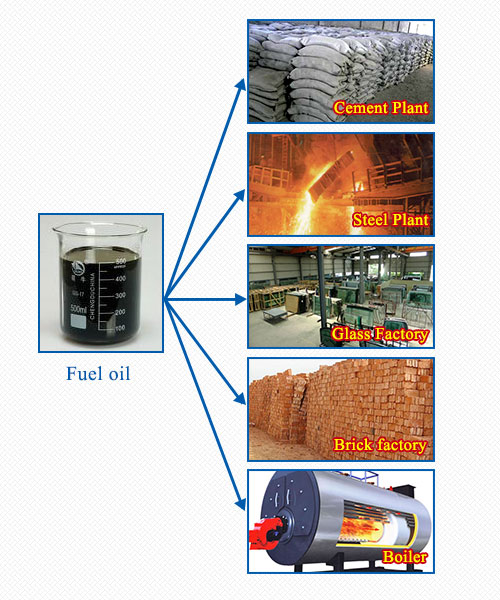

High technology environmental waste tire oil pyrolysis plant to fuel oil final product application

1.Fuel Oil (45% to 52%)

The main application of oil products produced by our waste tire oil pyrolysis plant to fuel oil machine is the fuel oil that is wide used for industrial and commercial purposes. Such as power plant factory,glass factory,cement factory,ceramic fatory.

Steel Wire (12% to 15%)waste tire oil pyrolysis plant to fuel oil machine is steel wire, the quantity of steel wire is about 10% to 15% according to tyre quality. It is very easy to sell steel wire scrape in local market.

Carbon Black (30%)

The second product of waste tire oil pyrolysis plant to fuel oil is carbon black. The quantity of carbon black is about 30% to 35% according to tyre quality. Carbon black can application to electric cable jacketing,black nylon bag,rubber additive

Exhaust gas (About 10%)

We get about 10% pyrolytic gases during pyrolysis process. The main component of this gases are methane (CH4), so we can not condense and store this gases. We use this gases to heat the reactor and we can use exceed gases for other heating application.

The keys of waste tire oil pyrolysis plant to fuel oil are reactor and cooling system

Reactor directly decides the machine's safety and service life. It is made by welded steel plate. So the quality of welding will have a direct impact on safety and service life. Therefore, we use automatic welding machine, X-rays detection and heating treatment which will not only guarantee the quality of welding but also greatly improve working efficiency.

Waste tire oil pyrolysis plant to fuel oil cooling systems decides oil output. There are two steps for cooling. Cooling pipe is the first step. The second is condenser. Its inner have 61 pipes in one condenser. The total cooling area is 100㎡. This will guarantee you a high oil yield. The reasonable design has a direct relationship with the oil output.