waste plastic pyrolysis to fuel oil

waste plastic pyrolysis to fuel oil

waste plastic pyrolysis to fuel oil

waste plastic pyrolysis to fuel oil

waste plastic pyrolysis to fuel oil

1.Whole tyre feed, no need to break, which reduces cost.

Adopt multilevel cooling circulation to get more fuel oil.

2. Discharge process through pulse dust removal processing, no dust emissions.

3. Easy operation, high efficiency and 2-3 people to operate.

Chat Online

Leave A Message

waste plastic pyrolysis to fuel oil feature

waste plastic pyrolysis to fuel oil machine

1.Whole tyre feed, no need to break, which reduces cost. waste plastic pyrolysis to fuel oil machine technical data

Technical parameter of waste plastic pyrolysis to fuel oil machine

No.

Items

Contents

1

Equipment type

DY-1-6

DY-1-8

DY-1-10

2

Raw material

Waste plastic

Waste plastic

Waste plastic

3

Structural form

Horizontal rotation

Horizontal rotation

Horizontal rotation

4

24-hour Capacity

6 ton

8 ton

10 ton

5

Oil yield

2.7-3.3ton

3.6 -4.4ton

4.5 -5.5ton

6

Operating pressure

Normal

Normal

Normal

7

Material of pyrolysis Reactor

Q245R

Q245R

Q245R

8

Thickness of pyrolysis Reactor

16mm

16mm

16mm

9

Rotate speed of pyrolysis Reactor

0.4turn/minute

0.4turn/minute

0.4turn/minute

10

Total power

19KW

19KW

19KW

11

Mode of cooling

Water cooling

Water cooling

Water cooling

12

Cooling area of condenser

100sqm

100sqm

100sqm

13

Kind of transmission

Internal gear drive

Internal gear drive

Internal gear drive

14

Noise dB(A)

≤85

≤85

≤85

15

Size of Reactor(D×L)

2200×6000

2200×6600

2600×6600

16

Working form

Intermittent operation

Intermittent operation

Intermittent operation

17

Delivery time

20days

20days

20days

18

Weight

27T

30T

35T

Prepared by customer about waste plastic pyrolysis to fuel oil machine

No.

Item

Consumption

1

Coal(for choice)

500kg/day

2

Wood(for choice)

800kg/day

3

Natural gas(for choice)

100-150kg/day

4

Oil(for choice)

300-350kg/day

5

Electricity

244kwh/day

6

Water(recycled)

60㎥ /month

7

Total power

19kw

8

Land area

35m*15m

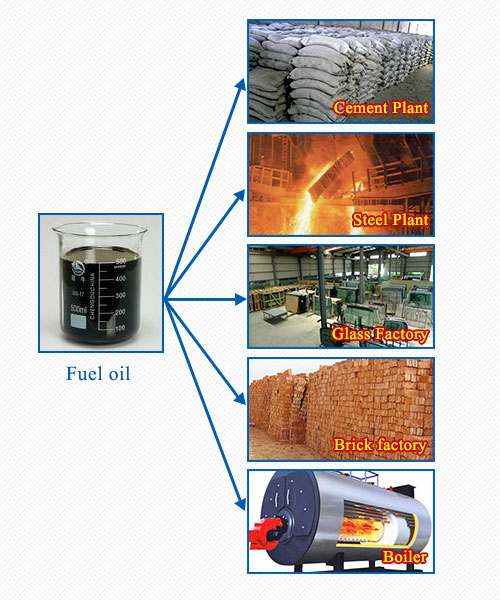

waste plastic pyrolysis to fuel oil machine final applicationfuel oil from waste tyre are used in below industries

Leave A Message About waste plastic pyrolysis to fuel oil

Title

Name

country

Email *

Tel

Inquiry

Send Message