Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

Video

-

DOING Waste Thermal Pyrolysis Equipment Feed-stocks Processing Demonstration

-

Semi-continuous and fully automatic pyrolysis equipment differences introduction video

-

DOING Advanced Continuous Pyrolysis Technology For Waste Recycling Display Video

-

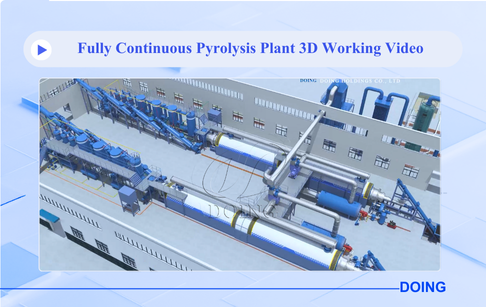

PLC control fully continuous pyrolysis technology 3D working video

-

14Ton waste oil recycling machine in Indonesia operation site

-

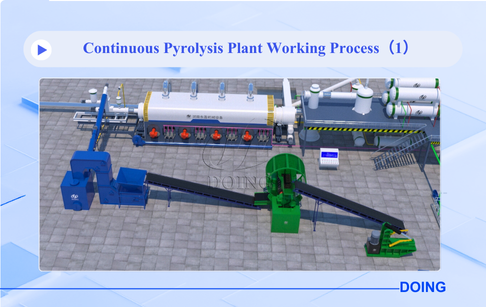

Fully continuous tire pyrolysis plant working process 1: waste tire pre-treatment

-

Semi-continuous tire pyrolysis machine process flow 3D video

-

Waste Oil Sludge Thermal Decomposition Units(TDU) Running Site Live Video

-

50TPD fully continuous tyre pyrolysis plant in India display video

-

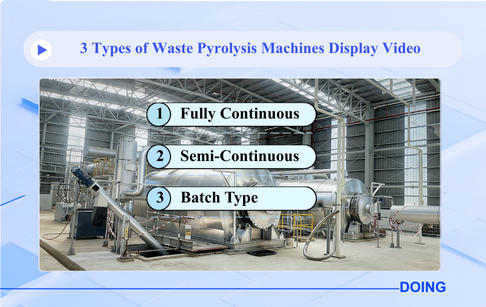

Three types of DOING waste tire pyrolysis plants real shot display video

Product

Project Case

-

DOING® Group|100 TPD Continuous Tire Pyrolysis Plants Installed for Repeat Client in China

-

Customized 1 Ton/Day Continuous Plastic Pyrolysis System Delivered for Korean Client

-

DOING DY-15 Waste Tire Pyrolysis Machine Project Successfully Installed in Kenya

-

DOING 45,000 Tons/Year Waste Plastic Pyrolysis Project in Vietnam Successfully Commissioned

-

DOING Tire & Plastic Pyrolysis Distillation Plant Successfully Installed in Fiji

-

DOING 50TPD Continuous Oil Sludge Pyrolysis Production Line Successfully Installed in China

-

DOING Installed 15-Ton Tank Bottom Sludge Pyrolysis Equipment for Colombian Repeat Client

-

DOING 30TPD Mazut Oil Distillation Plant Successfully Installed in Kazakhstan

-

-

DOING Three 15-ton Batch Tire Pyrolysis Units in Myanmar On-site Installation Experience

DOING Waste Thermal Pyrolysis Equipment Feed-stocks Processing Demonstration

2025-09-15 / Video / Get Price / Chat Online

Welcome to Henan Doing Company's video channel! As a professional manufacturer of thermal pyrolysis equipment, DOING Company is committed to providing global customers with efficient and environmentally friendly waste conversion solutions. Suitable for oil refineries and recycling companies, it is energy-saving, environmentally friendly, and offers a quick return on investment.

This video focuses on the core advantage of our pyrolysis equipment—flexible processing of various industrial raw materials, helping you achieve efficient recycling from waste.

DOIN pyrolysis equipment can process raw materials including, but not limited to:

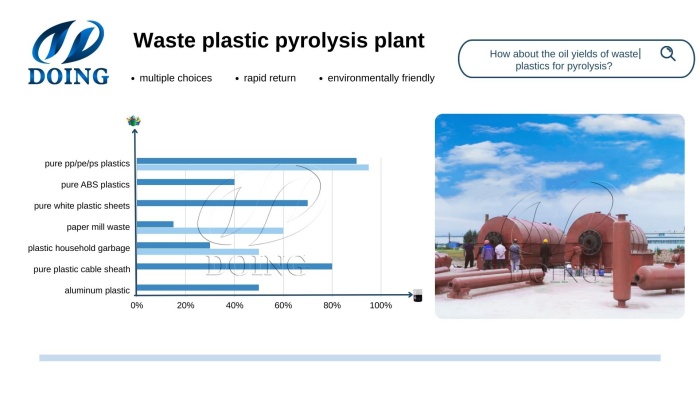

1. Waste Plastics

Applicable Types: Mixed plastics such as PP, PE, PS, and ABS

Processing Capacity: 5-50 tons per day (customizable)

Outputs: Pyrolysis oil, carbon black, combustible gas

Equipment Advantages: Special anti-coking design ensures uniform pyrolysis during the plastic melting stage.

Waste plastic feedstocks for thermal pyrolysis equipment

Waste plastic feedstocks for thermal pyrolysis equipment

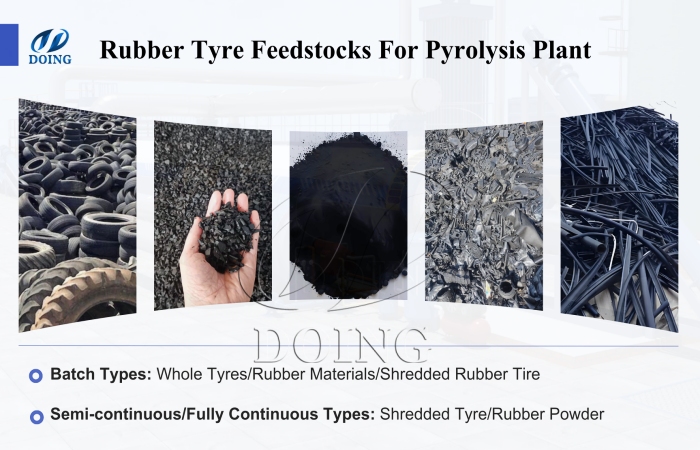

2. Waste Rubber Tire Raw Materials

Applicable Types: Passenger car tires, rubber scraps, rubber shealth, truck tires, construction machinery tires

Processing Capacity: Whole tires/rubber blocks can be processed.

Outputs: Pyrolysis oil, steel wire, carbon black

Equipment Advantages: Can be equipped with tire cutters, shredders, and tire steel wire separation systems to improve resource recovery rates.

Waste rubber tyre feedstocks for thermal pyrolysis equipment

Waste rubber tyre feedstocks for thermal pyrolysis equipment

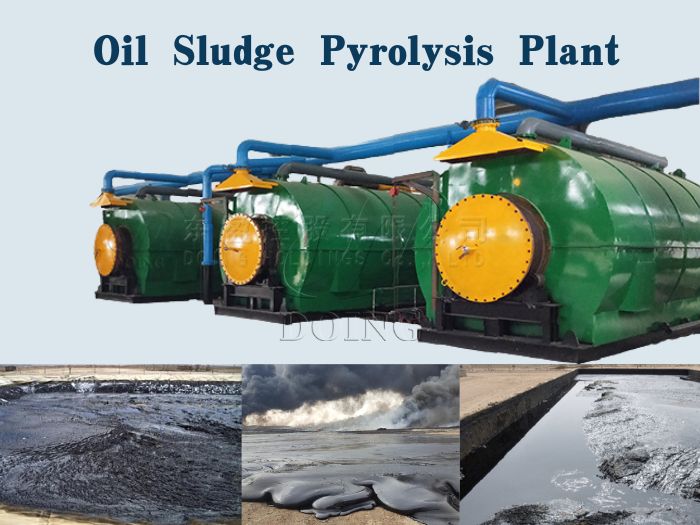

3. Oil Sludge and Oil contaminated

Applicable Types: Oilfield oil sludge mud/pit, refinery oil sludge, industrial oil sludge, oil refinery catalyst residues, OBDC (Oil-Based Drill Cuttings), coal tar residue, Oil shale,etc.

Processing Capacity: Oil sludge raw materials with a moisture content ≤30%

Outputs: Regenerated base oil, fuel oil

Equipment Advantages: High pyrolysis efficiency, high oil quality, enabling environmentally friendly treatment of oil-containing contaminants.

Waste oil sludge feedstocks for thermal pyrolysis equipment

Waste oil sludge feedstocks for thermal pyrolysis equipment

4. Biomass Raw Materials

Applicable Types: Rice husks, sawdust, palm shells, straw, coconut shell, wood, etc.

Processing Capacity: Biomass with a moisture content ≤15% (if not, before biomass pyrolysis process, the raw material need to be dehydrated)

Output Products: Biochar, wood vinegar, combustible gas

Equipment Advantages: Low-temperature pyrolysis technology, preserving biochar activity

5. Other Special Raw Materials

Organic Waste Materials / Wind Blower Blades / E-waste PCB Boards / Medical plastic waste / Aluminum-plastic composite materials, etc.

After watching the video, please contact us for customized waste pyrolysis solutions, free equipment selection reports, and quotations. Engineers and business managers at Henan Doing Company will combine our decades of experience in the pyrolysis industry to assist you in successfully implementing your thermal pyrolysis project!

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.