Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

Video

-

DOING Waste Thermal Pyrolysis Equipment Feed-stocks Processing Demonstration

-

Semi-continuous and fully automatic pyrolysis equipment differences introduction video

-

DOING Advanced Continuous Pyrolysis Technology For Waste Recycling Display Video

-

PLC control fully continuous pyrolysis technology 3D working video

-

14Ton waste oil recycling machine in Indonesia operation site

-

Fully continuous tire pyrolysis plant working process 1: waste tire pre-treatment

-

Semi-continuous tire pyrolysis machine process flow 3D video

-

Waste Oil Sludge Thermal Decomposition Units(TDU) Running Site Live Video

-

50TPD fully continuous tyre pyrolysis plant in India display video

-

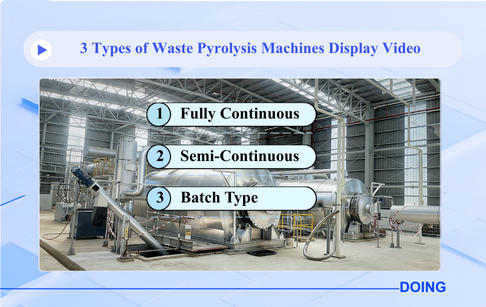

Three types of DOING waste tire pyrolysis plants real shot display video

Product

Project Case

-

DOING® Group|100 TPD Continuous Tire Pyrolysis Plants Installed for Repeat Client in China

-

Customized 1 Ton/Day Continuous Plastic Pyrolysis System Delivered for Korean Client

-

DOING DY-15 Waste Tire Pyrolysis Machine Project Successfully Installed in Kenya

-

DOING 45,000 Tons/Year Waste Plastic Pyrolysis Project in Vietnam Successfully Commissioned

-

DOING Tire & Plastic Pyrolysis Distillation Plant Successfully Installed in Fiji

-

DOING 50TPD Continuous Oil Sludge Pyrolysis Production Line Successfully Installed in China

-

DOING Installed 15-Ton Tank Bottom Sludge Pyrolysis Equipment for Colombian Repeat Client

-

DOING 30TPD Mazut Oil Distillation Plant Successfully Installed in Kazakhstan

-

-

DOING Three 15-ton Batch Tire Pyrolysis Units in Myanmar On-site Installation Experience

Semi-continuous and fully automatic pyrolysis equipment differences introduction video

2025-11-27 / Video / Get Price / Chat Online

Semi-continuous and fully automatic pyrolysis equipment are improved versions of batch pyrolysis machine. They process raw materials such as waste rubber powder, plastic granules, or oily sludge. They use a sealed feed auger and a sealed slag discharge auger, eliminating the need for furnace cooling and enabling continuous high-temperature slag discharge. So, what are the differences between semi-continuous and fully automatic pyrolysis equipment?

By watching this video, you can see the differences between semi-continuous and fully automatic equipment in terms of operation methods, applicable scenarios, and efficiency.

Semi-continuous Pyrolysis Equipment: Material is continuously input. Its operation involves three separate steps: feeding, pyrolysis, and slag discharge. No furnace cooling is required before slag discharge; slag is discharged directly at high temperature. It can process three furnaces of raw material in two days.

Fully Automatic Pyrolysis Machine: Material is continuously input and output at a fixed rate. Its operation involves simultaneous feeding, pyrolysis, and slag discharge. No shutdown is required, and it can operate continuously for 45-60 days.

Semi-continuous Pyrolysis Equipment: Suitable for scenarios with limited raw material, limited initial investment, or a focus on short-term profits, such as medium-sized waste recycling plants with a daily processing capacity of 5-20 tons/unit.

Fully Automatic Pyrolysis Machine: Suitable for scenarios with stable supply, sufficient funds, and a need for long-term economic benefits, such as large-scale waste recycling plants with a daily processing capacity of 15-50 tons/unit or more.

Differences of semi-continuous and fully automtic pyrolysis plants

Differences of semi-continuous and fully automtic pyrolysis plants

Semi-continuous Pyrolysis Equipment: Offers greater operational flexibility and lower investment, but its equipment utilization rate and efficiency are slightly lower than fully automatic equipment.

Fully Automatic Pyrolysis Machine: Higher investment, but high operating efficiency, high equipment utilization, and lower energy input, suitable for large-scale continuous production.

If you have specific technical details regarding semi-continuous and fully automatic pyrolysis equipment, and how well they match your waste treatment pyrolysis needs, please contact us. Our project managers and engineering team will customize the most cost-effective pyrolysis solution for you.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.