The Market Background of Aluminum Plastic Separator equipment

Aluminum plastic separator machine can bring a huge business opportunities.With the rapid development of modern industrial technology, plastic technology and products with each passing day, more and more plastic products have been widely applied to pe

2015

09/25

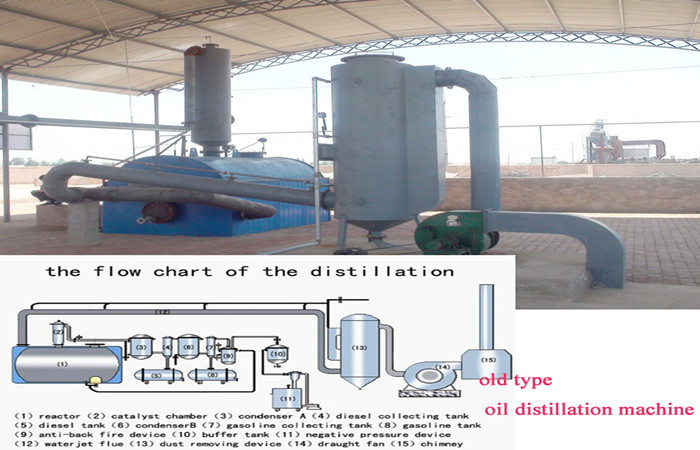

The comparison of new-tech distillation and old type one

Our new-tech oil distillation machine adopts indirect boiler heating system, there are spring-like conduction oil pipes inside the vertical distillation reactor(material -stainless steel), so that the crude oil inside can be fully distilled and has high oil yield of 85%. Meanwhile, indirect heating can greatly prolong the reactor life. In the operation of new-tech distillation machine, distillation, de-color and de-odor are three separated process to ensure the quality of the final diesel.The raw material for new-tech distillation machine include tyre oil, plastic oil and waste engine oil.

2015

09/05

How to recycle plastic waste with pyrolysis machine?

With the increasing of plastic products consumption, waste plastic is also growing. At present in the world, plastic waste are mainly as plastic film, plastic yarn and fabric, foam, plastic packaging and containers, daily plastic products, plastic bags, agricultural film, cars plastic and so on. Without proper processing, it will damage environment and harm to people’s health.

2015

09/05

The Classification of the Scrap Copper Granulator Machine

The so-called dry-type scarp copper granulator machine refers to the machine that do not add water during the processing. This type scarp copper granulator machine mainly used airflow sorting machine, or air shaker or electrostatic separation and other more environmentally friendly sorting methods. The main process is: smash - airflow separation - (electrostatic separation) - dust. (Electrostatic separation rarely in today's copper-meter machine used.)

2015

09/05

One recovered energy---fuel oil got from waste tyre

The most noticeable problem associated with large tyre piles is the fire hazard they present. Once a tyre pile catches fire, it is very hard, if not impossible, to extinguish. In some instances, tyre piles have been burning for several months with the black fumes being visible for many miles. Diseases such as encephalitis and dengue fever have also been reported around scrap tyre piles, particularly in areas with warmer climates which are an ideal breeding ground for disease-carrying mosquitoes. So it is important and urgent to manage the pollution and problems caused by waste tyres.

2015

08/28

Waste tire and plastic oil production line of China Doing Company

For the first line, its raw material will be scrap tires, plastics or other rubbers. After pyrolysis processing tires, the finally products are fuel oil, carbon black and steel wire. If your raw material is plastic, then you can get fuel oil and carbon black finally. The fuel oil is a kind of very good heating fuel which is widely used in cement factory, steel factory, boiler factory, brick factory, glass factory and so on. Except being sold as heating fuel, the oil also can be collected for further refining.

2015

08/28

What is carbon black briquette machine?

Carbon black briquette machine is mainly used for briquetting some powdery material which is difficult for molding. It has characteristics of big molding pressure, adjustable engine revolution and spiral feeding device. Briquette machine, also named b

2015

08/28

Pyrolysis plant in Romania

Romania customer visited us in Dec, 2012, who stayed China for studying waste tires and plastic pyrolysis equipment for more than 20days. Because it has very strict rule in importing waste tire and plastic pyrolysis equipment in his country. Not only machine quality is very important, but also the machine should be friendly to environment without any pollution. Therefore, Romania customer visited nearly all suppliers in China to compare the machine. Finally he chose us as his supplier because of our professional manufacture and strict testing on our equipment. Customer decided to cooperate with us after visited our factory. And he sent us the deposit soon after signed contract. Except Romania, we also exported our waste tire and plastic pyrolysis equipment to many other countries, such as Mexico, Haiti, Guatemala, Italy, Turkey, Poland, Bangladesh, India, Malaysia, and Thailand etc. We, Henan Doing Mechanical Equipment Co.,Ltd always improve our waste tire and plastic pyrolysis equipment and promote our technology. Customers success is Doings success. We will always supply you the best scheme, best equipment and best service. If you are interest in our waste tire and plastic pyrolysis equipment, welcome to contact us and get more useful information.

2015

08/22