Product

Project Case

-

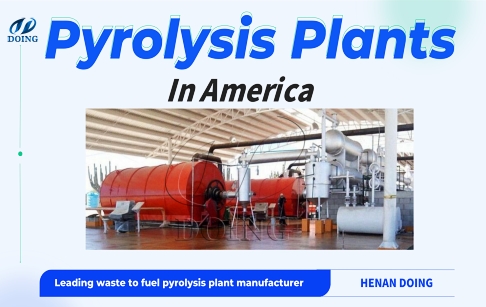

DOING 15 TPD semi-continuous tire pyrolysis equipment installed in Indonesia

-

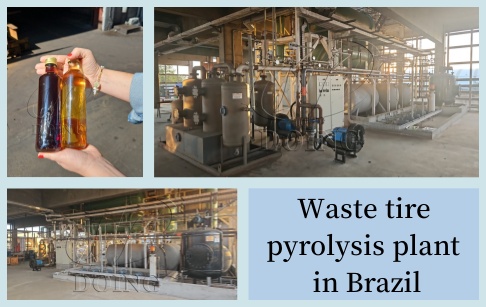

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

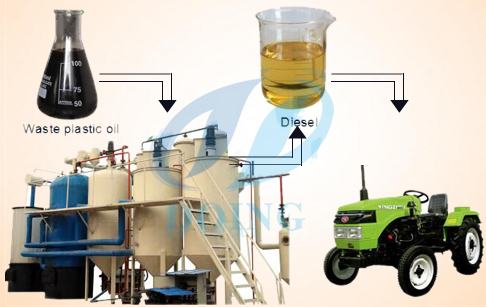

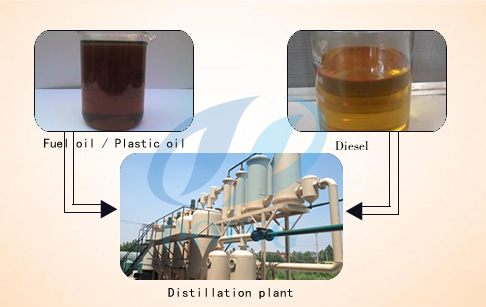

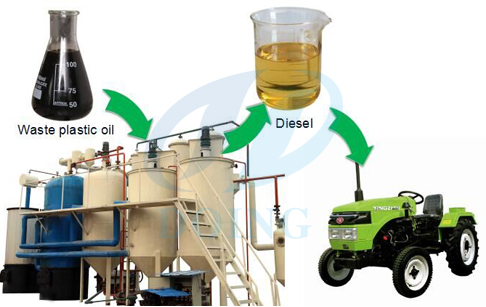

Plastic oil to diesel process machine

Waste plastic pyrolysis plant has supplied a new solution on disposal of waste plastic. Waste plastic pyrolysis plant ca...

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail: market@doingmachinery.com

E-mail: market@doingmachinery.com

- Features:

- Technical Data:

- Application:

Plastic products has been used widely, and waste plastic can be seen everywhere. It has seriously affected our environment on two aspects, such as visual pollution and potential hazards. Visual pollution means that aesthetic perception on living city affected by scrap plastic in everywhere. Potential hazards mainly refers to degradation-resistant of waste plastic affecting on absorbing of nutrients and water by crop, reducing the production; and otherwise, animals will be die if eats it unconscious. Recycling and utilization of waste plastic is increasingly becoming an important aspect for environmental protection. Waste plastic pyrolysis plant has supplied a new solution on disposal of waste plastic.

Plastic oil to diesel process machine

Plastic oil to diesel process machine successful installation in Mexico

Plastic oil to diesel process machine successful installation in Mexico

- Features:

- Technical Data:

- Application:

| Technical parameter of plastic oil to diesel process machine | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | motor oil, waste tire crude oil, plastic crude oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

- Features:

- Technical Data:

- Application:

Diesel from plastic oil to diesel process machine

Diesel oil application

Previous: Used motor oil recycling dispose equipment

Next: Waste oil to diesel

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.