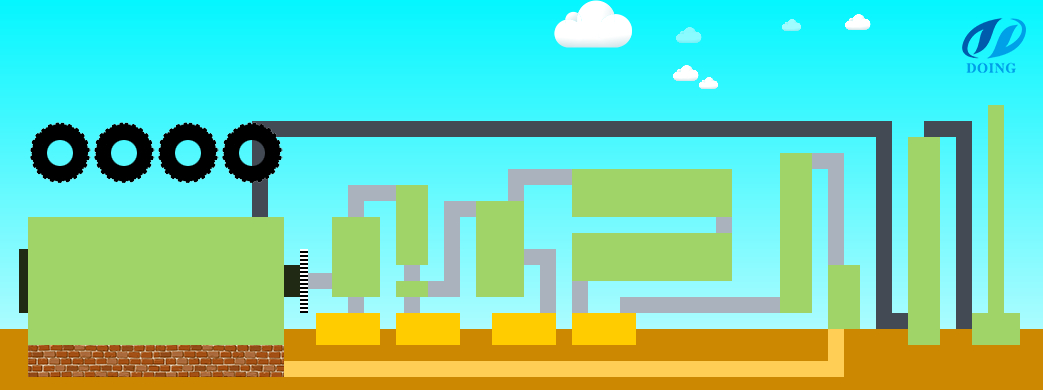

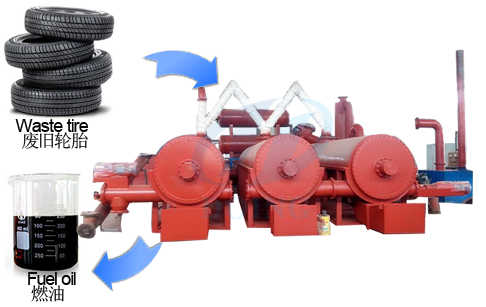

High technology fully continuous waste tire pyrolysis plant

Fully continuous waste tire pyrolysis plant

Fully continuous waste tire pyrolysis plant

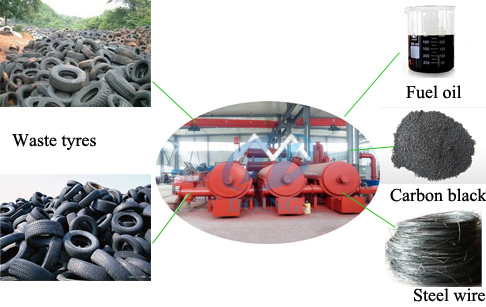

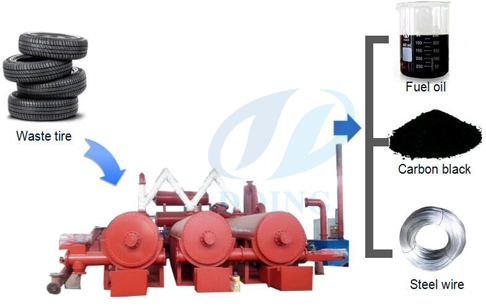

Waste tire is often called “black pollution”, because it not only easily causes fire, but also pollutes the environment. However, it is also a kind of valuable renewable resources for human beings. Through the use of fully continuous waste tire pyrolysis plant manufactured by Doing company. We can get three kinds of final products: 45%-52% tyre fuel oil, 30% carbon black, 12%- 15% steel wire and 10% gas . They all have a wide range of applications. For example, the tire fuel oil can be used as industrial fuel materials for burning, or further refined to diesel or gasoline. The carbon black can be used for construction bricks with clay or used as fuel. The steel wire can be re-sale or reprocessing. There is also a little combustible gas producing in the process, the gas can be recycled to heat the reactor as fuel, which will save energy for the whole working process.

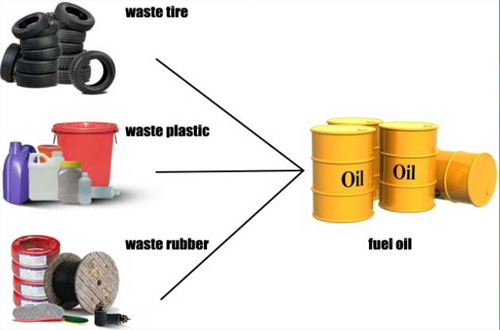

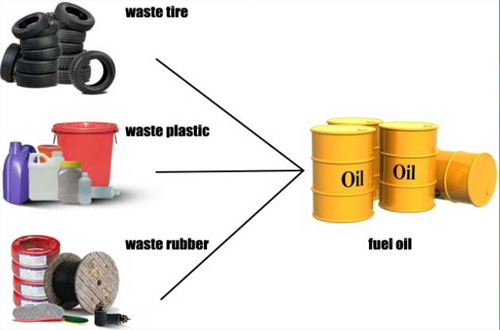

High technology fully continuous waste tire pyrolysis plant raw material

The raw material of high technology fully continuous waste tire pyrolysis plant

1.Waste tire/tyre

2.Waste plastic

3.Waste rubber

High technology fully continuous waste tire pyrolysis plant technical data

|

No. |

Item |

Specifications |

|

1 |

Model |

DY-C-10 |

DY-C-20 |

DY-C-30 |

DY-C-50 |

DY-C-60 |

DY-C-80 |

DY-C-100 |

|

2 |

Cpacity |

10T/D |

20T/D |

30T/D |

50T/D |

60T/D |

80T/D |

100T/D |

|

3 |

Power |

35Kw |

50Kw |

65Kw |

80Kw |

90Kw |

105Kw |

120Kw |

|

4 |

Working type |

Continuous |

|

5 |

Reactor deisgn |

Mutiple reactors (The quantity and size depends on the raw material condition) |

|

6 |

Rotating |

Internal rotating |

|

7 |

Cooling system |

Recycled waster cooling |

|

8 |

Reactor material |

Q245R/Q345R boiler plate |

|

9 |

Heating method |

Indireact hot air heating |

|

10 |

Heating fuel |

Fuel oil/gas |

|

11 |

Feedstock |

Waste tire/plastic/rubber |

|

12 |

Output |

Fuel oil, carbon black |

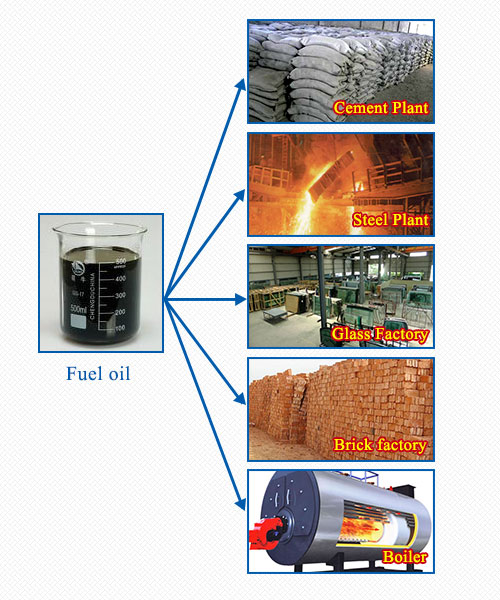

High technology fully continuous waste tire pyrolysis plant final product application

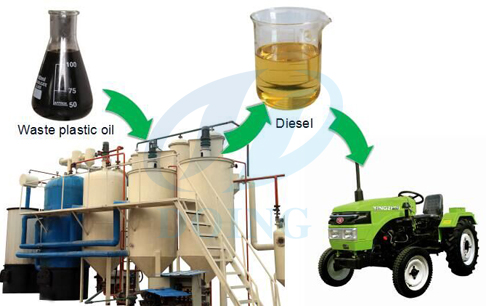

1.Fuel Oil (45% to 52%)

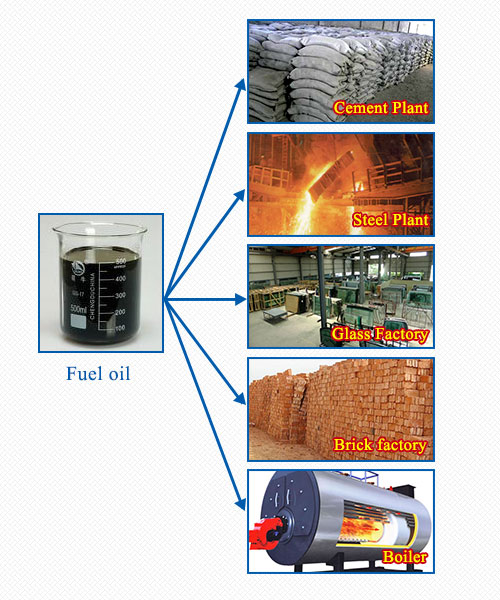

The main application of oil products produced by our fully continuous waste tire pyrolysis plant is the fuel oil that is wide used for industrial and commercial purposes. Such as power plant factory,glass factory,cement factory,ceramic fatory.

Steel Wire (12% to 15%) fully continuous waste tire pyrolysis plant is steel wire, the quantity of steel wire is about 10% to 15% according to tyre quality. It is very easy to sell steel wire scrape in local market.

Carbon Black (30%)

The second product of fully continuous waste tire pyrolysis plant to fuel oil is carbon black. The quantity of carbon black is about 30% to 35% according to tyre quality. Carbon black can application to electric cable jacketing,black nylon bag,rubber additive

Exhaust gas (About 10%)

We get about 10% pyrolytic gases during pyrolysis process. The main component of this gases are methane (CH4), so we can not condense and store this gases. We use this gases to heat the reactor and we can use exceed gases for other heating application.