Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

News

-

DOING News

-

Industry News

Product

Project Case

-

DOING Three 15-ton Batch Tire Pyrolysis Units in Myanmar On-site Installation Experience

-

India 50TPD Fully continuous rubber pyrolysis machine installed

-

DOING 15 TPD semi-continuous tire pyrolysis equipment installed in Indonesia

-

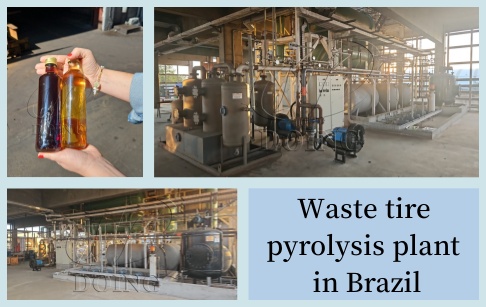

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

What is the waste tyre management strategy in South Africa?

2025-06-10 / Industry News / Leave Message / Chat Online

South Africa's waste management strategy is guided by national policies and legislation aimed at reducing waste generation, promoting recycling, and ensuring environmentally sound disposal.

In South Africa, tyre manufacturers and importers are required to ensure proper recycling or disposal of waste tyres.

The South African government encourages waste tyre recycling and even provides rebates to tyre recycling companies for proper and environmentally sound processing of waste tyres.

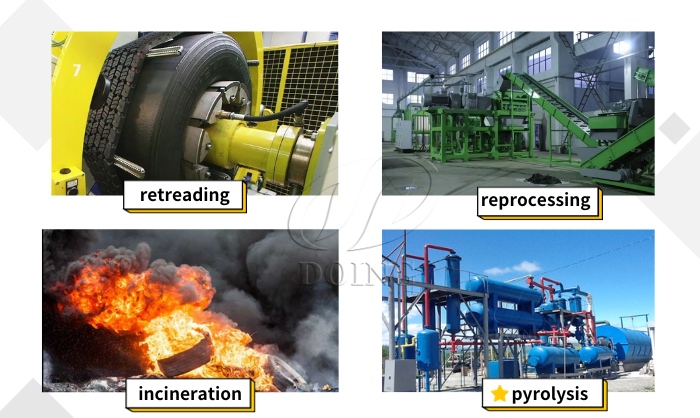

There are roughly four different methods for waste tyre recycling in South Africa:

Use of Scrap tyres: Scrap tyres can be repurposed as port fenders and ship fenders, slope protection levees, road traffic wall screens, signposts, marine aquaculture reefs, and amusement facilities. However, these applications are relatively limited. While this method helps reduce waste tyre stockpiles, it does not fully address the issue of waste tyre recycling and may pose certain environmental risks if not properly managed.

Recycling Scrap tyres into Rubber Powder or Reclaimed Rubber: This method involves high-temperature and high-pressure dynamic desulfurization processes. However, it generates secondary exhaust gas pollution and poses risks of burning and explosions during production. As a result, the production of reclaimed rubber has gradually declined, and some countries have discontinued its production.

Scrap tyre Retreading: This method requires high integrity of the tyres and strict retreading technology standards. Moreover, retreaded tyres may still pose significant safety hazards.

Scrap tyre Pyrolysis to Produce Fuel Oil: With the development of high-value-added economic technologies, "thermal cracking" technology has been continuously refined. Used tyre pyrolysis technology has quietly progressed to the stage of industrial development due to its unique advantages. This offers an optimal solution for waste tyre recycling, eliminating secondary pollution, alleviating energy crises, and achieving resource recycling.

Waste tyre recycling methods

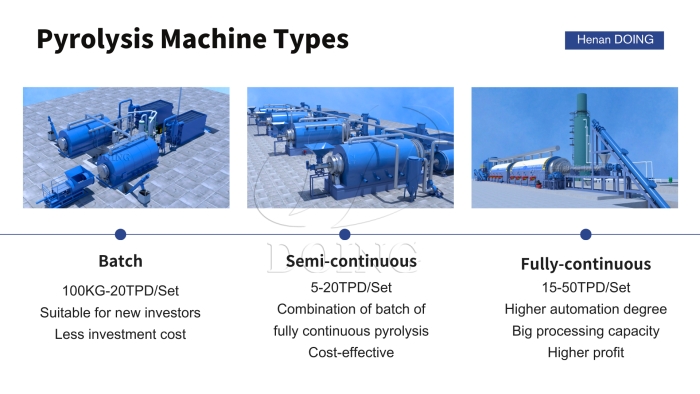

DOING provides a variety of pyrolysis plant to meet different needs. Batch pyrolysis plant is suitable for small-scale intermittent processing, with simple design and low investment cost. Semi-continuous pyrolysis plant combines the advantages of intermittent and full continuous, and is economical and efficient. Full continuous pyrolysis plant can operate 24 hours a day, with high production efficiency and high safety and environmental protection coefficient.

DOING pyrolysis plants types

DOING rotary automatic pyrolysis plants adopt low-temperature and vacuum pressure cracking technology for used tyres. Through pyrolysis treatment, used tyres are converted into recyclable carbon black and fuel oil, transforming black waste into renewable resources. This technology enables waste tyres to re-enter the production cycle as raw materials, effectively controlling environmental pollution while facilitating resource recycling. It delivers significant social and economic benefits and has become a new economic growth point for industrial recycling. Compared with other tyre treatment methods, tyre pyrolysis plants are highly recommended.

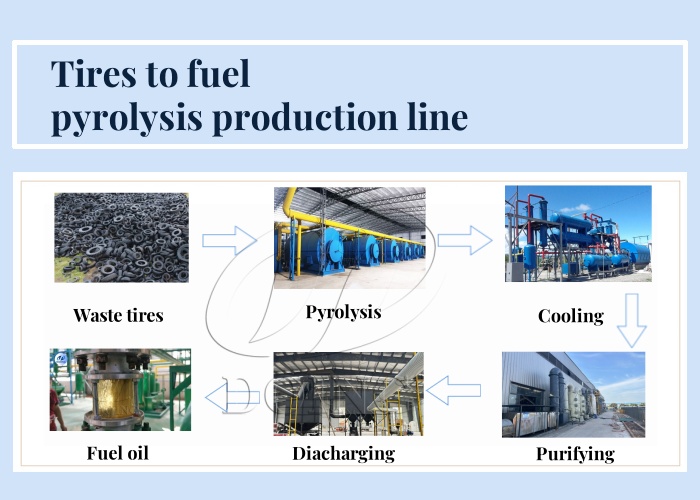

Waste tyre pyrolysis production line

Waste tyre pyrolysis products and products' usages

In conclusion, South Africa's waste tyre management strategy encompasses various methods, among which waste tyre pyrolysis recycling stands out as a promising solution. With the increasing demand for waste tyre recycling, pyrolysis recycling is expected to become one of the mainstream methods for waste tyre treatment. As a professional waste tyre pyrolysis plant manufacturer, DOING Company is committed to providing high-quality pyrolysis equipment and technical support to help more countries and regions address their waste tyre issues.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.