Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

Project Case

-

DOING Three 15-ton Batch Tire Pyrolysis Units in Myanmar On-site Installation Experience

-

India 50TPD Fully continuous rubber pyrolysis machine installed

-

DOING 15 TPD semi-continuous tire pyrolysis equipment installed in Indonesia

-

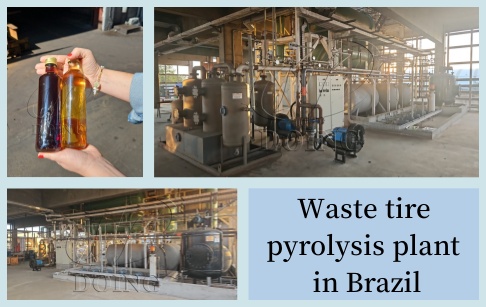

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

Product

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

DOING Three 15-ton Batch Tire Pyrolysis Units in Myanmar On-site Installation Experience

2025-01-30 / In Asia / Leave Message / Chat Online

DOING is pleased to share our project experience of successfully installing three 15-ton batch tire pyrolysis units in Myanmar in January 2025. This project served a client in the mining and lime production industry.

DOING batch tire pyrolysis unit in Myanmar installation site

This Myanmar client, recognizing the enormous potential of abundant waste tire resources to be converted into cost-effective lime kiln fuel, embarked on his tire pyrolysis business. After initial contact and comprehensive evaluation in early 2023, they ultimately selected DOING's pyrolysis technology and equipment, and officially launched the installation project of the three 15-ton batch tire pyrolysis units in in January 2025.

DOING batch tire pyrolysis unit in myanmar delivery

The installation of these batch tire pyrolysis units is a meticulous process, meticulously supervised by our engineers from start to finish. The entire process begins with foundation engineering. Crucially, for the side-discharge system selected by the customer, detailed foundation drawings were provided in advance. This enabled the correct construction of the reinforced concrete supports for the reactor and pre-excavated carbon black discharge pit, ensuring long-term stability and efficient operation.

The subsequent physical installation follows a precise sequence:

Reactor Assembly: The pyrolysis reactor, the core component of the system, is carefully lifted into place. Its base, support wheels, drive system, and critical sealing components are positioned and assembled.

System Integration: The buffer tank is connected to the reactor, ensuring perfect alignment. Subsequently, the oil storage tank is positioned, and the water-box condenser system is lifted into place.

Piping and Auxiliary Equipment: All interconnecting piping is welded and secured. The water seal and dust removal/desulfurization systems are installed, and finally, the carbon black lifting system is installed.

DOING batch tire pyrolysis unit in Myanmar installation site

This structured installation approach, guided by our experienced team, ensures the proper integration of every component, from feedstock to final off-gas treatment. The flexibility of our batch pyrolysis units enables our customers to efficiently process scrap tires, producing high-value fuel oil for their own use, transforming a waste problem into an energy solution while significantly reducing operating costs.

DOING batch tire pyrolysis unit manufaturer

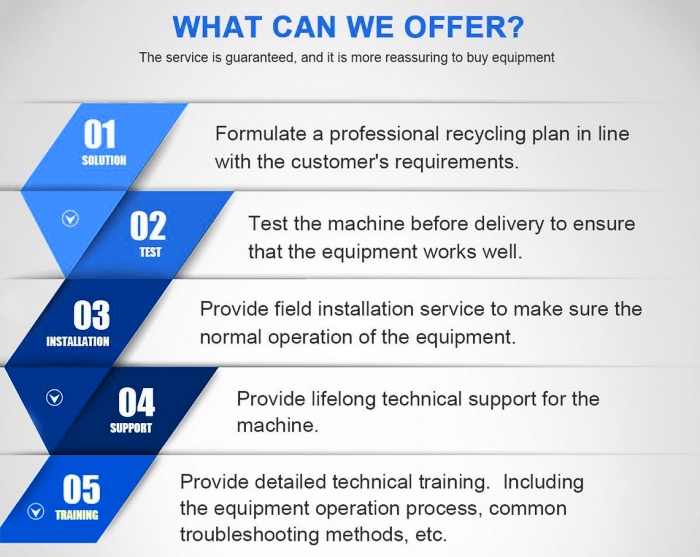

DOING is committed to continuously innovating our pyrolysis technology and improving the quality of our pyrolysis units, ensuring we provide you with a professional and reliable waste recycling solution. If you are considering a waste pyrolysis business, please contact DOING.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.