Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

News

-

DOING News

-

Industry News

Product

Project Case

-

DOING Three 15-ton Batch Tire Pyrolysis Units in Myanmar On-site Installation Experience

-

India 50TPD Fully continuous rubber pyrolysis machine installed

-

DOING 15 TPD semi-continuous tire pyrolysis equipment installed in Indonesia

-

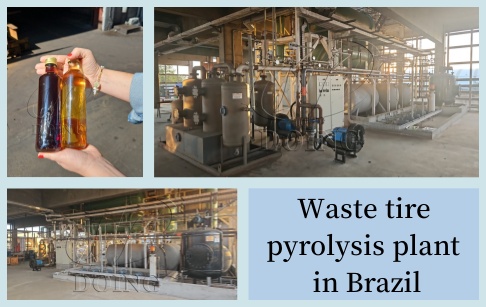

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

What' the tyre oil extraction rate? How to improve it?

2025-05-22 / Industry News / Leave Message / Chat Online

In the rapidly growing field of waste tyre recycling pyrolysis, understanding the tyre oil extraction rate is essential for businesses aiming to maximize profitability and efficiency. The tyre oil extraction rate refers to the efficiency with which oil can be extracted from waste tyres through pyrolysis. Typically, the yield of oil from tyre pyrolysis ranges from about 30% to 55% of the tyre's weight, depending on several factors including the type of tyres, their composition, and the specific conditions used in the pyrolysis process. This passage will introduce you in details.

Factors Affecting Tyre Oil Extraction Rate

Tyre Composition: Different types of tyres have varying compositions, affecting the amount of oil that can be extracted. For example, tyres with a higher proportion of natural and synthetic rubber tend to produce more oil. All kinds of rubber sheets or carpets have an oil extraction rate of 30%; unclassified rubbers, rubber cable sheath and rubber soles have an oil extraction rate of 35%; motorcycle and bicycle tyres have an oil extraction rate of 35%-40%; Large vehicle tyres, such as those from trucks and buses, have an oil extraction rate of 45% - 52%.

Pyrolysis Temperature: The temperature at which pyrolysis occurs significantly impacts the oil yield. Optimal temperatures typically range between 400°C and 500°C. Too low temperatures may result in incomplete conversion, while too high temperatures might promote gas production over oil. The most suitable temperature for tyre pyrolysis is around 280-320°C.

Waste tires pyrolysis machine product applications

Waste tires pyrolysis machine product applications

Heating Rate and Residence Time: Rapid heating rates and appropriate residence times ensure efficient breakdown of tyre materials into oil, char, and gases. Fine-tuning these parameters can enhance oil yields.

Reactor Design: Efficient reactor designs that provide uniform heating and good contact between the tyre material and heat source contribute to better oil extraction rates.

How to Improve Tyre Oil Extraction Rate

Optimize Pyrolysis Conditions: Adjusting the temperature, heating rate, and residence time based on the tyre type and desired product distribution can lead to improved oil yields. DOING provides intelligent PLC control system, This system precisely monitors and adjusts the pyrolysis temperature, pressure, and other parameters in real - time, optimizing the extraction process for maximum oil yield.

Improve Reactor Efficiency: Upgrading to more advanced reactor systems designed for optimal heat transfer and material processing can increase oil extraction rates. DOING waste tyre pyrolysis reactors are made of national standard materials and can be customized with stainless steel for a longer service life.

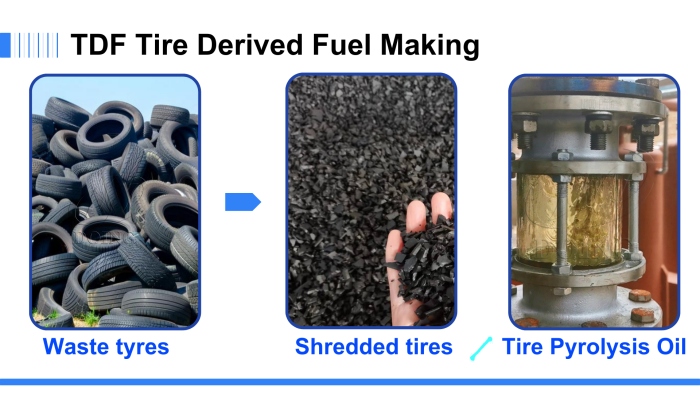

Pre-treatment of Tyres: Shredding tyres into smaller pieces before pyrolysis increases the surface area exposed to heat, potentially leading to higher oil yields. DOING provides you with pretreatment equipment, such as steel wire drawing machines, tyre shredder, tyre baler, tyre steel wire circle cutter, tyre cut-off machine and rubber powder processing equipment.

Tire derived fuel making machine

Tire derived fuel making machine

To improve the tyre oil extraction rate, in addition to choosing the right type of waste tyres, investing in high - quality pyrolysis equipment like DOING is crucial. DOING provides comprehensive after - sales services, including installation, training, and maintenance, ensuring that customers can use the equipment smoothly and efficiently. DOING waste tyre pyrolysis equipment offers a reliable and efficient solution for achieving higher extraction rates and sustainable waste management. If you want to know more details about the pyrolysis oil, Welcome to contact us.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.