Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

News

-

DOING News

-

Industry News

Product

Project Case

-

DOING® Group|100 TPD Continuous Tire Pyrolysis Plants Installed for Repeat Client in China

-

Customized 1 Ton/Day Continuous Plastic Pyrolysis System Delivered for Korean Client

-

DOING DY-15 Waste Tire Pyrolysis Machine Project Successfully Installed in Kenya

-

DOING 45,000 Tons/Year Waste Plastic Pyrolysis Project in Vietnam Successfully Commissioned

-

DOING Tire & Plastic Pyrolysis Distillation Plant Successfully Installed in Fiji

-

DOING 50TPD Continuous Oil Sludge Pyrolysis Production Line Successfully Installed in China

-

DOING Installed 15-Ton Tank Bottom Sludge Pyrolysis Equipment for Colombian Repeat Client

-

DOING 30TPD Mazut Oil Distillation Plant Successfully Installed in Kazakhstan

-

-

DOING Three 15-ton Batch Tire Pyrolysis Units in Myanmar On-site Installation Experience

Shipment of waste tire doubling and tripling machine to Bolivia

2024-11-26 / DOING News / Leave Message / Chat Online

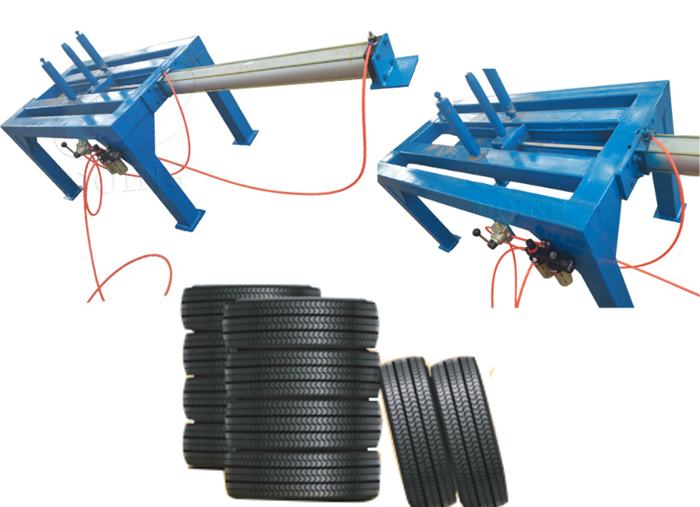

Congratulation! DOING complete the shipment of the waste tire doubling and tripling machine purchased by a Bolivian customer on October 30,2024. It only took ten days from ordering to shipment. Here is a picture of shipment:

Waste tire doubling and tripling machine shipped to Bolivia

Waste tire doubling and tripling machine shipped to Bolivia

Bolivian customer is a waste tire recycler. Because the large number of recycled waste tires and high transportation costs, the customer wants to buy a waste tire doubling and tripling machine to improve the utilization of transportation space and reduce costsreduce the cost. After learned that, DOING sales manager carefully introduced the waste tire packing machine's model, operation, customer cases and the service. Bolivian customer took the order for the waste tire doubling and tripling mahcine finally.

Bolivia waste tire doubling and tripling machine

Bolivia waste tire doubling and tripling machine

Before shipment, DOING and the Bolivian customer had a video call to test the feasibility of the waste tire doubling and tripling machine and check the integrity of the waste tire doubling and tripling machine. The Bolivian customer expressed his satisfaction. The DOING staff packed the waste tire doubling and tripling machine carefully. About 30 days later, the Bolivian customer will receive the waste tire doubling and tripling machine. DOING will provide Bolivian customer with a video guide for waste tire doubling and tripling machine installation, from the display of waste tire doubling and tripling machine accessories to the detailed installation process, for customer reference.

DOING waste tire doubling and tripling machine is equipped with an air compressor, whose control system is intelligent and can automatically adjust the air pressure and flow, reduce manual intervention, reduce the workload of operators, and improve overall work efficiency. It can also provide higher working pressure and flow under the same energy consumption, reducing energy consumption.

Excepe for the waste tire doubling and tripling machine purchased by Bolivian customers, DOING has various tire treating machine, such as waste tire shredder, single-side tire steel wire circle cutter, both-side tire steel wire circle cutter, steel wire pulling machine, waste tire pyrolysis reactor and pyrolysis production line. If you want to treat your waste tire, just feel free to contact us.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.