Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

News

-

DOING News

-

Industry News

Product

Project Case

-

DOING® Group|100 TPD Continuous Tire Pyrolysis Plants Installed for Repeat Client in China

-

Customized 1 Ton/Day Continuous Plastic Pyrolysis System Delivered for Korean Client

-

DOING DY-15 Waste Tire Pyrolysis Machine Project Successfully Installed in Kenya

-

DOING 45,000 Tons/Year Waste Plastic Pyrolysis Project in Vietnam Successfully Commissioned

-

DOING Tire & Plastic Pyrolysis Distillation Plant Successfully Installed in Fiji

-

DOING 50TPD Continuous Oil Sludge Pyrolysis Production Line Successfully Installed in China

-

DOING Installed 15-Ton Tank Bottom Sludge Pyrolysis Equipment for Colombian Repeat Client

-

DOING 30TPD Mazut Oil Distillation Plant Successfully Installed in Kazakhstan

-

-

DOING Three 15-ton Batch Tire Pyrolysis Units in Myanmar On-site Installation Experience

What kind of energy is produced by waste recycling using pyrolysis equipment, how is this energy used?

2026-02-05 / Industry News / Leave Message / Chat Online

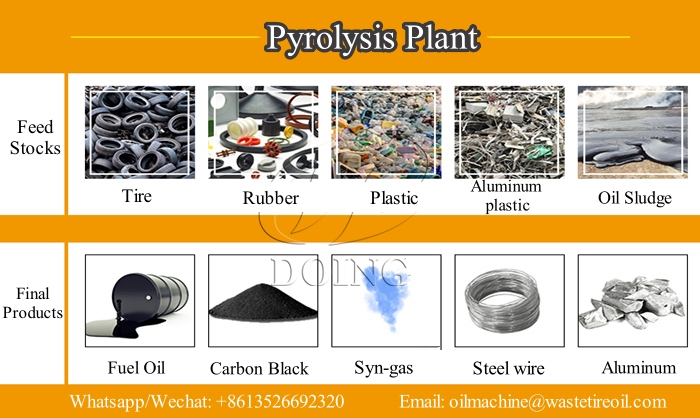

In waste recycling using pyrolysis equipment, the process typically yields three main types of energy products: syngas, pyrolysis oil, and solid residues like carbon black. These outputs vary slightly depending on the input waste— for example, scrap tires might produce more carbon black, while plastics yield higher volumes of oil.

Final products of waste pyrolysis equipment

1. Liquid Energy Products: Pyrolysis Oil

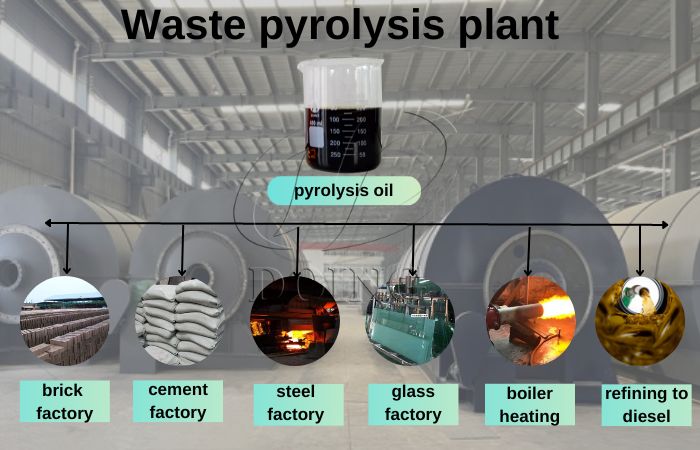

Pyrolysis oil is one of the main energy products from waste pyrolysis recovery. It is formed by the vaporization and condensation of complex organic compounds in waste during the pyrolysis process. This oil has a calorific value (typically 30-40 MJ/kg) similar to heavy fuel oil, thus serving as a substitute for fossil fuels in many applications.

The type and yield of pyrolysis oil depend on the type of input waste. For example, pyrolysis of waste plastics typically produces a high-quality pyrolysis oil with low sulfur content, suitable for clean combustion. Oil from waste tires has a higher viscosity and is rich in aromatic compounds; while oil sludge from oil extraction is easier to pyrolyze and refine due to its inherent hydrocarbon content.

Plastic and tire pyrolysis oil

Uses of pyrolysis oil:

Industrial fuel: Typically burned in boilers or kilns to provide heat for manufacturing processes such as cement production or metal smelting. This provides a cost-effective alternative to traditional fuels, reducing dependence on primary petroleum.

Power generation: Pyrolysis oil can be blended with traditional fuels to fuel diesel engines or turbines in small heavy oil power plants, generating electricity for local grids or off-grid communities.

Further refining: Through distillation and catalytic treatment, pyrolysis oil can be upgraded into diesel fuel for use in large machinery, ships, generators, etc.

Uses of waste pyrolysis oil

2. Solid Energy Products: Solid Products

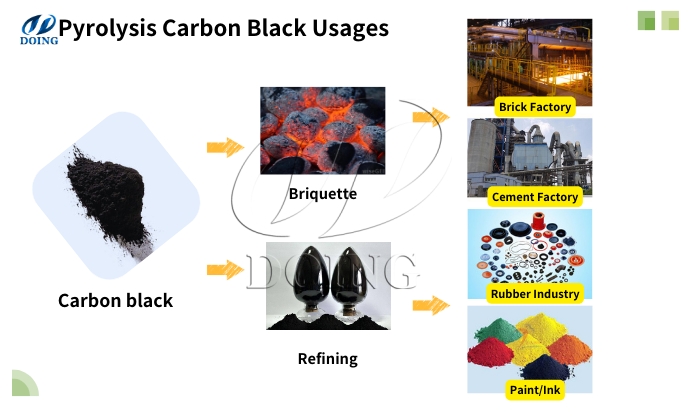

Solid residues from pyrolysis, such as carbon black, account for 20% to 40% of the total output, depending on the type of waste. These residues retain a high carbon content, giving them excellent fuel properties, and can also be used for non-energy purposes.

For waste tires and plastics, the solid product is primarily carbon black, while sludge typically produces slag or inert residues after hydrocarbon removal.

Main Applications:

Bulching and Combustion: Carbon black from pyrolysis can be directly briquetted and burned as solid fuel, or it can be mixed with fuel from coal-fired power plants to produce steam for power generation. Its calorific value (approximately 25-30 MJ/kg) is comparable to coke, providing heat energy for industrial heating systems.

Besides energy applications, carbon black is widely used as a reinforcing agent in rubber products such as tires and hoses to improve their durability. It can also be processed for use as a black pigment in inks, coatings, and plastics. Slag from sludge pyrolysis is typically used as filler in building materials (such as bricks or roadbeds) or, after treatment, safely landfilled.

Applications of pyrolysis carbon black

3. Gaseous Energy Products: Pyrolytic Syngas

Syngas is the gaseous product of pyrolysis, consisting mainly of hydrogen (H₂), methane (CH₄), carbon monoxide (CO), and some carbon dioxide. It makes up 10-15% of the total output and is produced as vapors that don't condense into oil. The gas composition varies by feedstock—for example, plastic waste generates syngas rich in hydrogen, while tires produce more CO-heavy mixes.

A key advantage of syngas in pyrolysis systems lies in its energy self-sufficiency. While an initial heat input is required to begin the pyrolysis process, the syngas produced after the process starts can be collected, purified, and then recycled back to the pyrolysis reactor for combustion to sustain the reaction.

Common Applications:

Self-heating of Pyrolysis Equipment: Syngas can be recycled during pyrolysis to provide the necessary heat to the reactor. This closed-loop approach improves energy efficiency, reduces the use of external energy sources, and to some extent reduces fuel costs associated with pyrolysis.

Power Generation and Heating: Purified syngas can be used as fuel for gas engines, turbines, or boilers for power generation or heating. However, pyrolysis equipment generally does not have the capability to store syngas. If you wish to store syngas for power generation in other systems, you will need to equip yourself with this equipment.

DOING pyrolysis equipment syngas recycling system

The Value of Waste Pyrolysis for Energy Recovery

Waste pyrolysis can convert non-recyclable materials into usable energy forms, solving key waste management challenges.

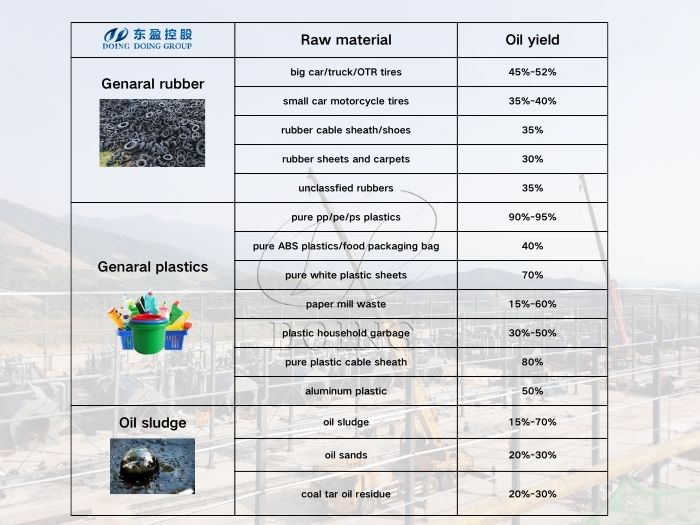

High Energy Recovery Rate: Pyrolysis can recover 70-80% of the energy from waste, far superior to incineration and landfill disposal, avoiding energy waste.

Raw material pyrolysis oil yield

Environmental Benefits: Waste pyrolysis reduces landfill space and greenhouse gas emissions, while also reducing secondary pollutants such as dioxins produced by waste incineration, significantly reducing pollution to soil, water, and air.

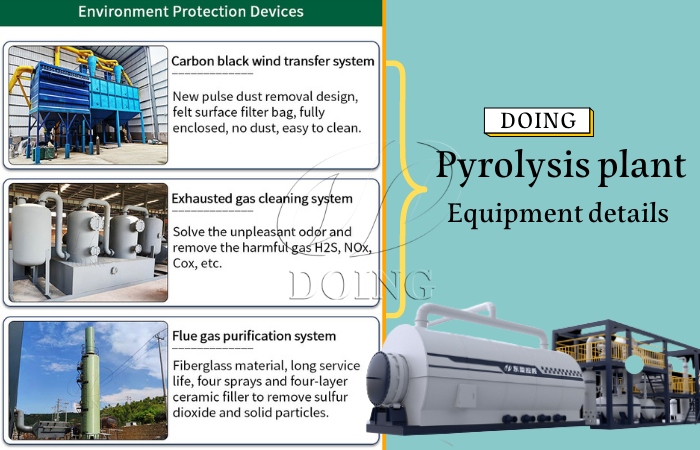

DOING pyrolysis equipment environment protection devices

Economic Benefits: The various products generated by pyrolysis—fuel oil, carbon black—create income streams and reduce the burden of waste management, making it particularly suitable for communities dealing with large quantities of tires, plastics, or industrial sludge, contributing to the goals of sustainable energy and a circular economy.

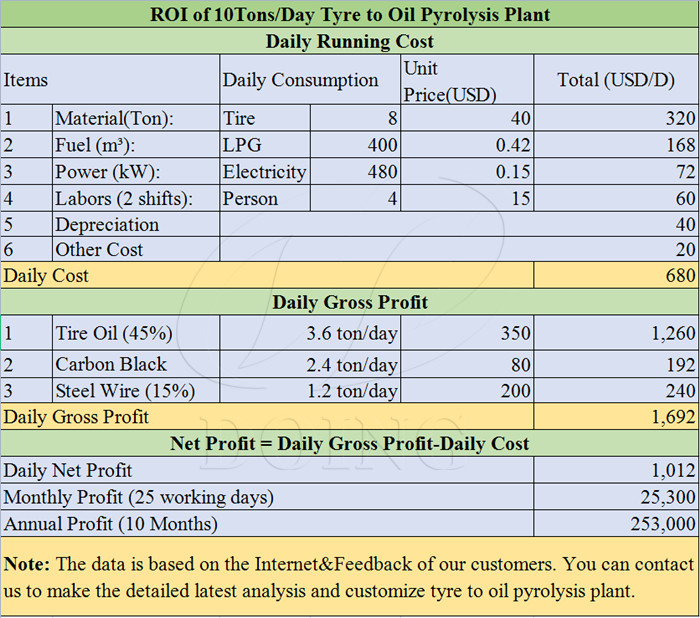

Waste recycling pyrolysis profit analysis

As a Chinese supplier specializing in waste pyrolysis technology, DOING Company is committed to providing batch, semi-continuous, and fully continuous pyrolysis equipment capable of efficiently processing various solid wastes such as waste tires, waste plastics, oil sludge, and coal tar residue. We offer comprehensive technical solutions to help customers achieve energy and resource recycling from waste. If you would like to learn more about our pyrolysis technology and services, please feel free to contact us.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.