Product

Project Case

-

-

DOING Three 15-ton Batch Tire Pyrolysis Units in Myanmar On-site Installation Experience

-

India 50TPD Fully continuous rubber pyrolysis machine installed

-

DOING 15 TPD semi-continuous tire pyrolysis equipment installed in Indonesia

-

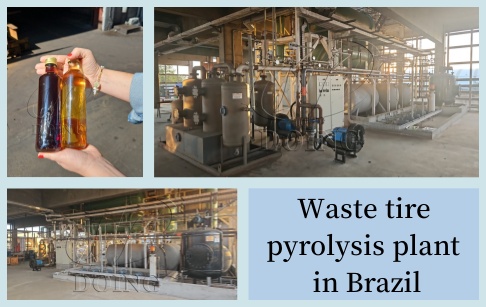

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

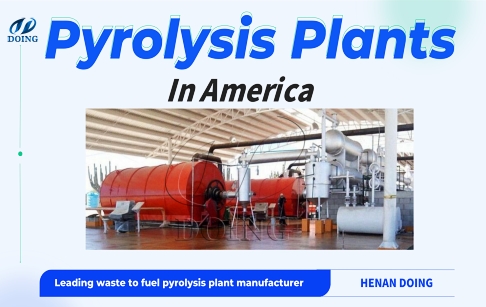

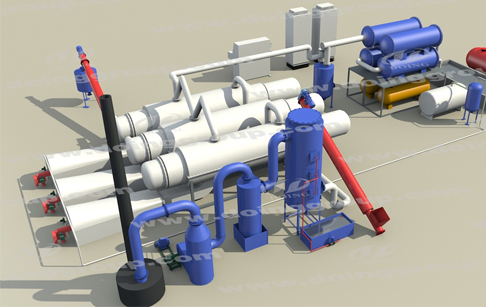

High technology fully continuous waste tire pyrolysis plant

Through the use of fully continuous waste tire pyrolysis plant manufactured by Doing company.The main application of oil...

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail: market@doingmachinery.com

E-mail: market@doingmachinery.com

- Features:

- Technical Data:

- Application:

Fully continuous waste tire pyrolysis plant

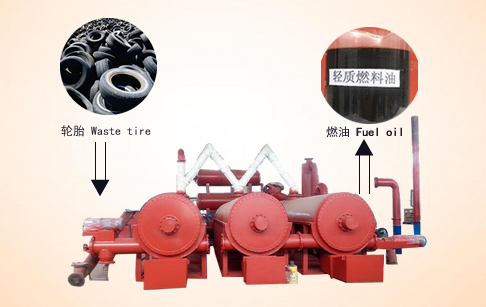

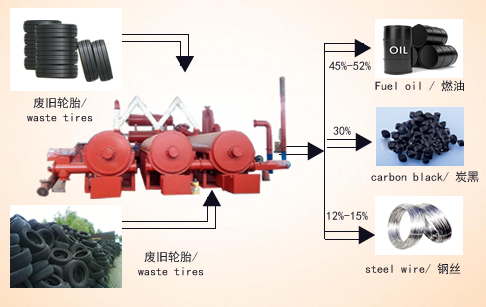

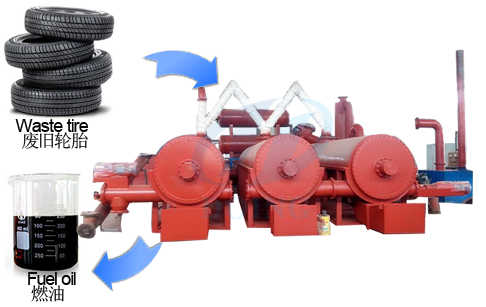

Through the use of fully continuous waste tire pyrolysis plant manufactured by Doing company. We can get three kinds of final products: 45%-52% tyre fuel oil, 30% carbon black, 12%- 15% steel wire and 10% gas . They all have a wide range of applications. For example, the tire fuel oil can be used as industrial fuel materials for burning, or further refined to diesel or gasoline. The carbon black can be used for construction bricks with clay or used as fuel. The steel wire can be re-sale or reprocessing. There is also a little combustible gas producing in the process, the gas can be recycled to heat the reactor as fuel, which will save energy for the whole working process.

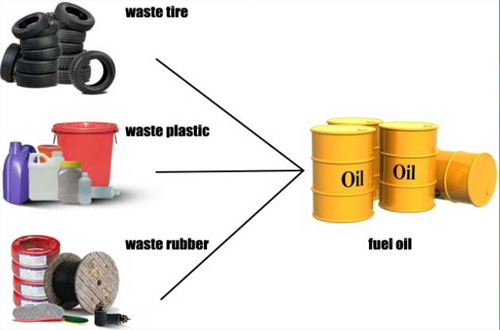

High technology fully continuous waste tire pyrolysis plant raw material

The raw material of high technology fully continuous waste tire pyrolysis plant

1.Waste tire/tyre

2.Waste plastic

3.Waste rubber

High technology fully continuous waste tire pyrolysis plant

High technology fully continuous waste tire pyrolysis plant

The waste tire is shredded into proper tire chips and continuously to be fed into the reactor for the normal pressure low temperature pyrolysis together with the low temperature sulfur transfer catalyst through the hot sealed device.

The pyrolyst oil gas is turned into fuel oil and little combustible gas (recycling use after scrubbing) after fractionation and cooling through oil separator.

High technology fully continuous waste tire pyrolysis plant

The solid output—raw carbon black and steel will be separated by magnetic separator. The raw carbon black will be automatically transferred to the carbon black production system and the industrial grade carbon black will be obtained after a serious of processes like milling etc. or will get other kinds of high-value chemical material. The separated steel could be sold as scrap steel. The combustible gas will be totally used as fuel to the system after scrubbing process.

The heating system adopts residual heat recycling technology, which far saving energy consumption and low down the running cost. The gas produced by the production line will be purified to meet the environmental standard then discharged.

- Features:

- Technical Data:

- Application:

| No. | Item | Specifications | ||||||

| 1 | Model | DY-C-10 | DY-C-20 | DY-C-30 | DY-C-50 | DY-C-60 | DY-C-80 | DY-C-100 |

| 2 | Cpacity | 10T/D | 20T/D | 30T/D | 50T/D | 60T/D | 80T/D | 100T/D |

| 3 | Power | 35Kw | 50Kw | 65Kw | 80Kw | 90Kw | 105Kw | 120Kw |

| 4 | Working type | Continuous | ||||||

| 5 | Reactor deisgn | Mutiple reactors (The quantity and size depends on the raw material condition) | ||||||

| 6 | Rotating | Internal rotating | ||||||

| 7 | Cooling system | Recycled waster cooling | ||||||

| 8 | Reactor material | Q245R/Q345R boiler plate | ||||||

| 9 | Heating method | Indireact hot air heating | ||||||

| 10 | Heating fuel | Fuel oil/gas | ||||||

| 11 | Feedstock | Waste tire/plastic/rubber | ||||||

| 12 | Output | Fuel oil, carbon black | ||||||

- Features:

- Technical Data:

- Application:

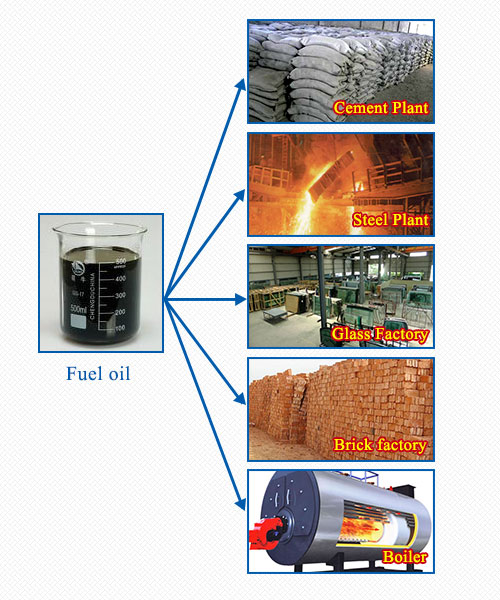

Fuel oil application

Fuel Oil (45% to 52%)

The main application of oil products produced by our fully continuous waste tire pyrolysis plant is the fuel oil that is wide used for industrial and commercial purposes. Such as power plant factory,glass factory,cement factory,ceramic fatory.

Steel Wire (12% to 15%) fully continuous waste tire pyrolysis plant is steel wire, the quantity of steel wire is about 10% to 15% according to tyre quality. It is very easy to sell steel wire scrape in local market.

Carbon Black (30%)

The second product of fully continuous waste tire pyrolysis plant to fuel oil is carbon black. The quantity of carbon black is about 30% to 35% according to tyre quality. Carbon black can application to electric cable jacketing,black nylon bag,rubber additive

Exhaust gas (About 10%)

We get about 10% pyrolytic gases during pyrolysis process. The main component of this gases are methane (CH4), so we can not condense and store this gases. We use this gases to heat the reactor and we can use exceed gases for other heating application.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.