Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

Product

Project Case

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

-

50TPD fully continuous waste tyre pyrolysis plant installed in Russia

-

50TPD continuous waste rubber tire pyrolysis machine put into operation in India!

-

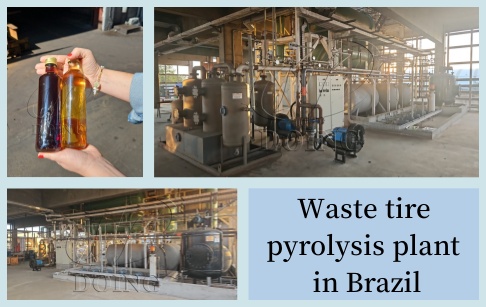

50 TPD fully continuous pyrolysis plant project installed in Brazil

-

-

What are the steps of waste tire pyrolysis to oil?

2023-07-18 / Continuous Pyrolysis plant / Leave Message / Chat Online

Now the waste tire pyrolysis industry is getting more attention all over the world. Because the waste tire will be converted into liquid oil by pyrolysis equipment, this fuel oil can be used as a kind of good petroleum alternative fuel and has a good market. I am writing about the steps to the waste tire to oil pyrolysis process to better understand with you.

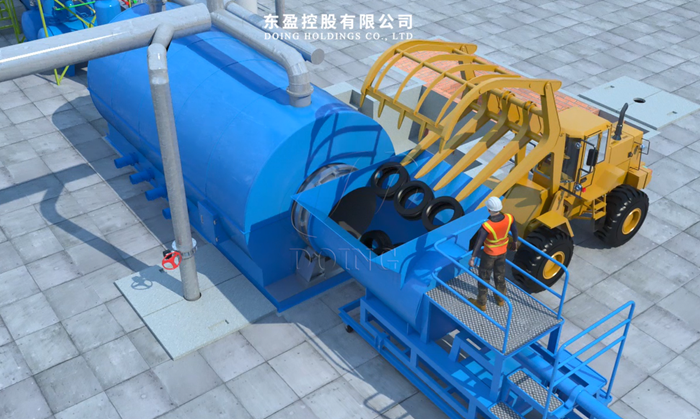

The first step, we need to feed the raw material into the reactor of waste tire pyrolysis equipment. The feeding methods you can choose are manual forklift, auto feeders with a grabbing machine or conveyor. The automatic feeding system is more efficient and time-saving. Taking our 12 TPD batch tire pyrolysis equipment as an example, it will take 1.5-2 hours to fill it with automatic feeding system, but manual feeding will take 4-5 hours.

The feeding step of waste tire pyrolysis process

The feeding step of waste tire pyrolysis process

Note: The batch type equipment processes the whole tire, while the semi-continuous and continuous type equipment needs to process the tire into rubber powder first.

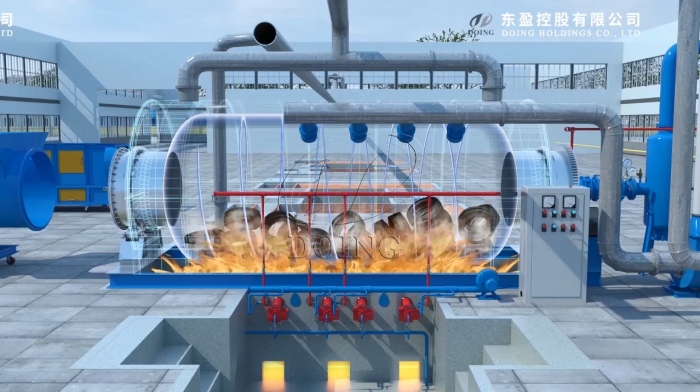

The second step, starting to heat the reactor, then the waste tire will be heated under high temperature and oxygen-free conditions. When the temperature rises to a certain degree, the oil gas and carbon black will come out.

Heating the pyrolysis reactor

Heating the pyrolysis reactor

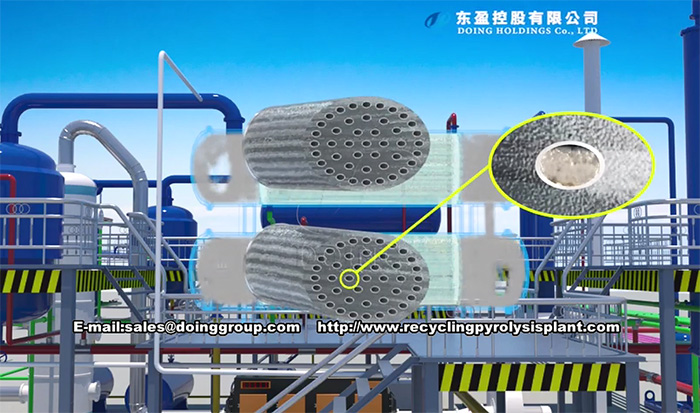

The third step is the cooling part. We have two types of cooling devices, which are a water tank and condensers with many pipes inside, and they each have their own characteristics. Their similarity is that they both use circulating cooling water, achieving zero discharge of waste water and almost no water consumption. And they completely ensure the oil yield, and help our customers make more profits.

DOING tubular condenser of pyrolysis equipment

DOING tubular condenser of pyrolysis equipment

The forth step is the last step, collecting the end products of waste tire pyrolysis. The fuel oil is collected in the oil tank after cooling; the carbon black in the batch tire to oil machine needs to be discharged after the reactor is cooled, and the carbon black in the semi-continuous and continuous tire to oil machine can be directly discharged; the combustible gas is transported to the reactor for use as fuel after oil-gas separation; the non-combustible gas is treated by the desulfurization tower and the deodorization system rear discharge.

The fuel oil of waste tire pyrolysis

The fuel oil of waste tire pyrolysis

The above are the steps of waste tire pyrolysis to oil. Different types of pyrolysis equipment have different processing techniques. For specific steps, please refer to our related videos.

Henan Doing Group is a leader in waste tire pyrolysis equipment in China. If you are interested in our machine, please feel free to contact us. Our waste tire pyrolysis equipment has high oil yield and high efficiency, which will make your project more efficient and profitable, and our sales&engineers team will provide the best service for you, including answering questions, solution design, installation guidance, after-sales service, etc..

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.