Product

Project Case

-

DOING 15 TPD semi-continuous tire pyrolysis equipment installed in Indonesia

-

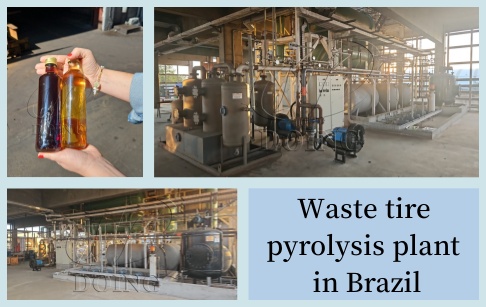

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

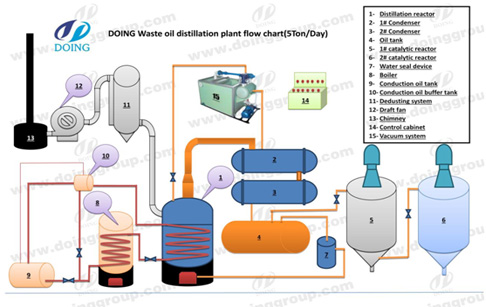

Crude oil refining process plant

Crude oil refining process plant use the theory of distillation, a green technology. The whole refining process includ...

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail: market@doingmachinery.com

E-mail: market@doingmachinery.com

- Features:

- Technical Data:

- Application:

Crude oil refining process plant

Crude oil refining process plant

Crude oil refining process plant working process

Crude oil refining process plant

- Features:

- Technical Data:

- Application:

| Technical parameter of vacuum distillation of crude oil plant | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | motor oil, waste tire crude oil, plastic crude oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

- Features:

- Technical Data:

- Application:

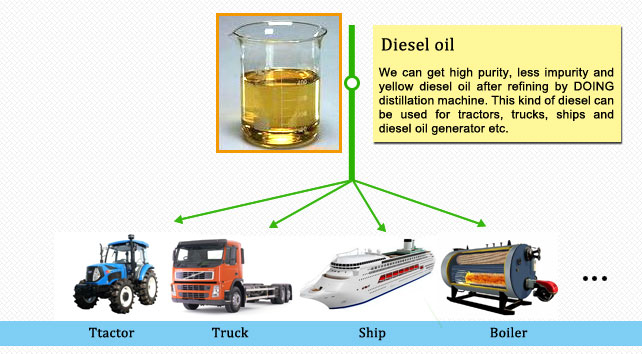

Products of crude oil refining plant include 85% diesel, 10% asphalt, 5% water and other impurities.

Diesel application

Previous: Nothing

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.