Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

Video

-

DOING Waste Thermal Pyrolysis Equipment Feed-stocks Processing Demonstration

-

Semi-continuous and fully automatic pyrolysis equipment differences introduction video

-

DOING Advanced Continuous Pyrolysis Technology For Waste Recycling Display Video

-

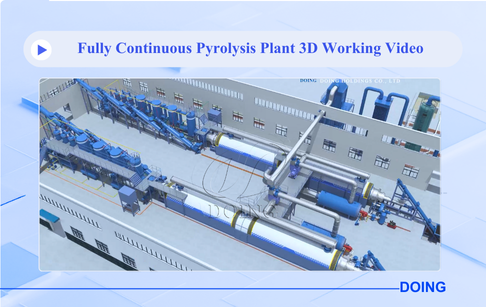

PLC control fully continuous pyrolysis technology 3D working video

-

14Ton waste oil recycling machine in Indonesia operation site

-

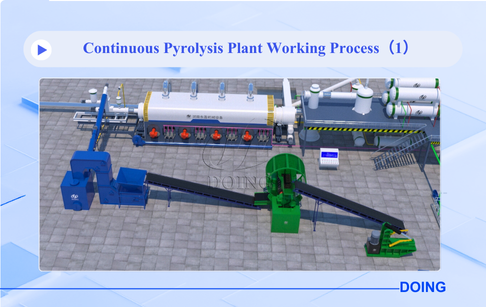

Fully continuous tire pyrolysis plant working process 1: waste tire pre-treatment

-

Semi-continuous tire pyrolysis machine process flow 3D video

-

Waste Oil Sludge Thermal Decomposition Units(TDU) Running Site Live Video

-

50TPD fully continuous tyre pyrolysis plant in India display video

-

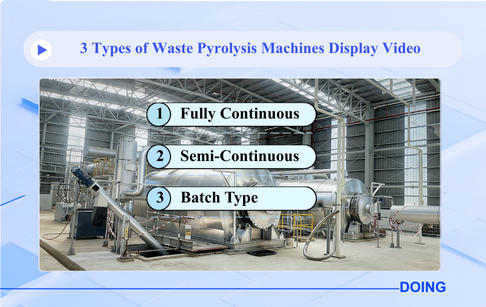

Three types of DOING waste tire pyrolysis plants real shot display video

Product

Project Case

-

DOING® Group|100 TPD Continuous Tire Pyrolysis Plants Installed for Repeat Client in China

-

Customized 1 Ton/Day Continuous Plastic Pyrolysis System Delivered for Korean Client

-

DOING DY-15 Waste Tire Pyrolysis Machine Project Successfully Installed in Kenya

-

DOING 45,000 Tons/Year Waste Plastic Pyrolysis Project in Vietnam Successfully Commissioned

-

DOING Tire & Plastic Pyrolysis Distillation Plant Successfully Installed in Fiji

-

DOING 50TPD Continuous Oil Sludge Pyrolysis Production Line Successfully Installed in China

-

DOING Installed 15-Ton Tank Bottom Sludge Pyrolysis Equipment for Colombian Repeat Client

-

DOING 30TPD Mazut Oil Distillation Plant Successfully Installed in Kazakhstan

-

-

DOING Three 15-ton Batch Tire Pyrolysis Units in Myanmar On-site Installation Experience

50TPD fully continuous waste tire pyrolysis plant in China operation video

2024-02-11 / Video / Get Price / Chat Online

This video mainly shows you the operation situation of DY-50TPD fully continuous waste rubber tire pyrolysis plant in China manufactured by Henan Doing Company. This pyrolysis project can process 50ton waste rubber tires into fuel oil and carbon black. Compared with other waste rubber tire treatment methods like landfill or buring, this tire recycling pyrolysis project is more environmentally friendly. At the same time, it can create more benefits.

To meet different requirements of customers, we can customize the fully continuous waste tire pyrolysis plant with the processing capacity from 15TPD to 50TPD. If you have bigger capacity or industrial scale waste rubber tyre recycling requirements, you can also contact us for detailed solutions.

The fully continuous waste tire pyrolysis plant has the features of high oil yield, high automation degree, environmental protection, high stability, energy saving, etc. Please don’t hesitate to contact us to learn more about it and get the free quote!

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.