Waste tire

As people are more and more concerning about the health and environmental, the disposal of various types of wastes, such as waste plastic, waste tyre, waste rubber, medical waste, municipal solid waste and other wastes, becomes more and more urgent problem all over the world and is the current topic. Many people want to recycle tires.

Continuous automatic recycling tyre oil plant

The investment of continuous automatic recycling tyre oil plant for the waste car and truck tire becomes one of the most profitable and promising industry .Doing continuous automatic recycling tyre oil plant is famous for their fully automatic with low labour cost,fully pyrolysis for high oil output,big capacity.

Continuous automatic recycling tyre oil plant

Continuous automatic tyre oil plant is a significant improvement based on the existing intermittent tyre oil plant at home and abroad, continous automatictyre oil plant fully realize the automatic operation ,continous automatic tyre oil plant Reactor than the intermittent pyrolysis plant can prolong life 5-6 year.

Continuous automatic recycling tyre oil plant

Continuous automatic recycling tyre oil plant raw material

1.Waste tire/tyre

2.Waste plastic

3.Waste rubber

Continuous automatic recycling tyre oil plant raw material

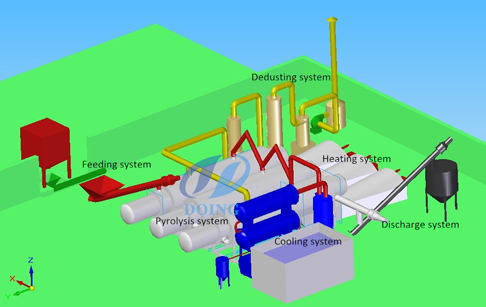

Continuous automatic recycling tyre oil plant working process

To keep continuous feeding and discharge system, it requires the waste tires should be in small size. So before continuous pyrolysis process, the waste tires should be shredded into small pieces. And to avoid the steel wire mix with carbon black after pyrolysis process which is difficult to separate, it’s better to remove the steel wire from waste tires at first. As for detailed process, please check as below:

Continuous automatic recycling tyre oil plant

1. Collect waste tires: All kinds of waste tires are available, from small car tires to big OTR tires.

2. Remove steel wire: Use a steel wire pulling machine to pull out the steel wire from waste tires. The steel wire pulling machine is operated automatically, which only need one work for operation.

3. Shred tires: Use a specialized tire shredder to process big whole tires into 3-5cm small pieces for easy feeding. The tire shredder is a single and fully automatic shredding system, which can be directly connected to the feeding system of the continuous pyrolysis plant, which no need any transfer process.

4. Continuous pyrolysis process: Shredded tires go into the continuous waste tyre pyrolysis plant, will firstly go through a mutiple pyrolysis reactor system to be pyrolyzed into oil gas. And oil gas will be cooling down to liquid oil through the cooling system. The residues (carbon black) will be pushed by continuous feeding tires to the carbon black dischrge system for discharge.

Continuous automatic recycling tyre oil plant advantage

1.Feeding in every seond and minute

2.Automatic ejiecting wastes residue

3.Fuel product day and night

4.Safe operation ,save manpower

5.Production efficiency.improve efficiency

6.Durable ,prolong life

Continuous automatic tyre oil plant picture show

Picture show of continuous automatic recycling tyre oil plant