Product

Product

Continuous scrap tire pyrolysis production line

Continuous scrap tire pyrolysis production line

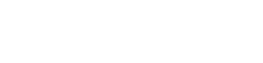

DOING latest continuous scrap tire pyrolysis production line is to convert waste tire/plastic to fuel oil, carbon black and steel through continuous waste tyre pyrolysis plant, instead of many other suppliers provide batch system to treat with waste tires and plastics.

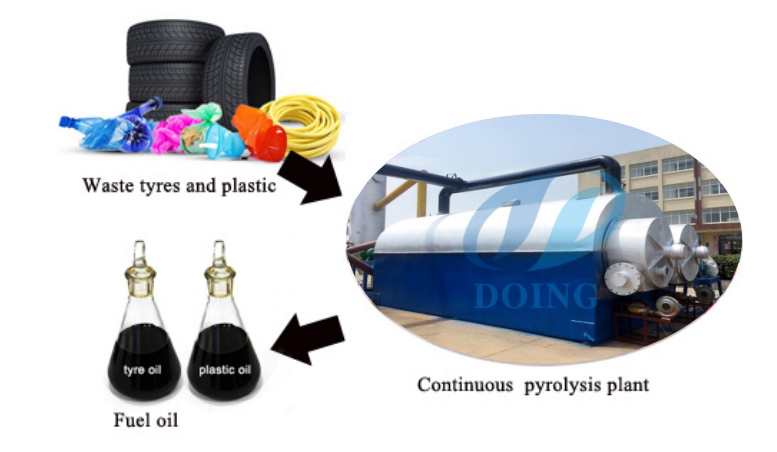

Continuous scrap tire pyrolysis production line 3D picture

Continuous scrap tire pyrolysis production line 3D picture

Doing’s continuous scrap tire pyrolysis production line is working under safety and environmental protection and will convert the waste tires to 45-52% fuel oil, 30-35% carbon black, 12-15% steel and 10% combustible gas All those outputs are able to be upgraded by further processing.

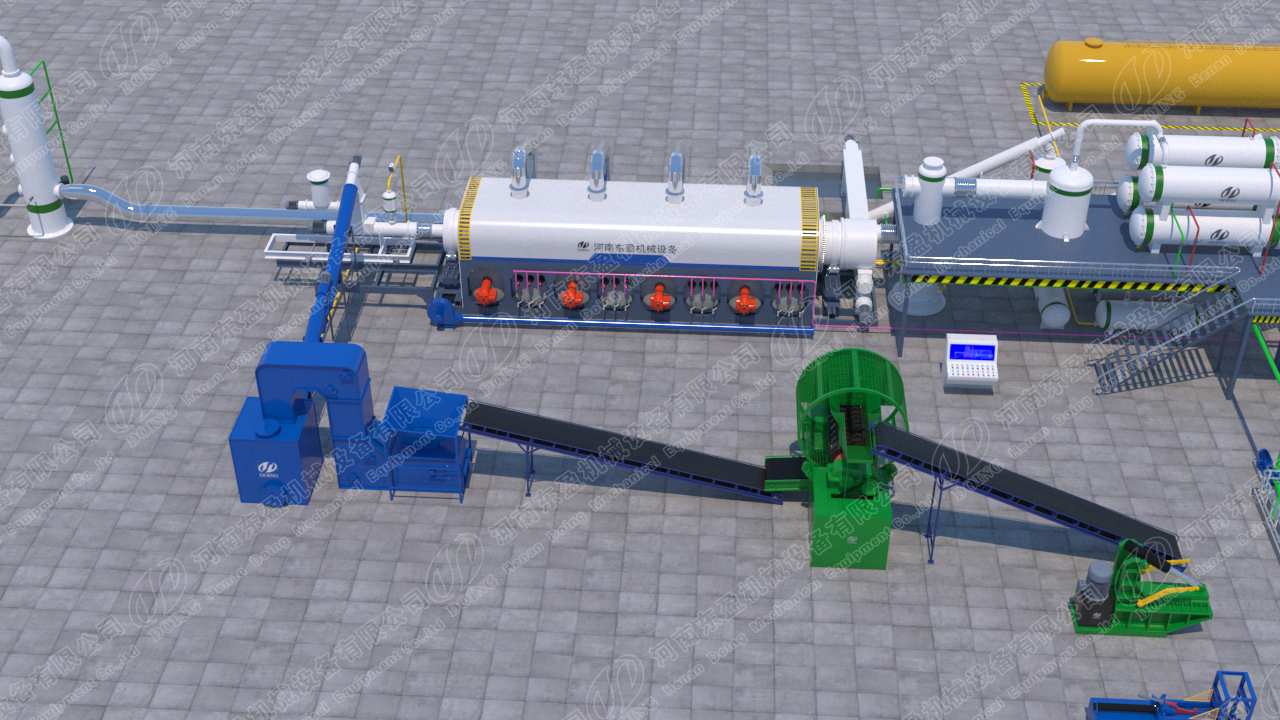

Continuous scrap tire pyrolysis production line pyrolysis process

Continuous scrap tire pyrolysis production line pyrolysis process

Continuous scrap tire pyrolysis production line pyrolysis process

1. The scrap tire is shredded into proper tire chips and continuously to be fed into the reactor for the normal pressure low temperature pyrolysis together with the low temperature sulfur transfer catalyst through the hot sealed device.

2. The pyrolyst oil gas is turned into fuel oil and little combustible gas (recycling use after scrubbing) after fractionation and cooling through oil separator.

3. The solid output—raw carbon black and steel will be separated by magnetic separator. The raw carbon black will be automatically transferred to the carbon black production system and the industrial grade carbon black will be obtained after a serious of processes like milling etc. or will get other kinds of high-value chemical material. The separated steel could be sold as scrap steel.

4. The combustible gas will be totally used as fuel to the system after scrubbing process. The heating system adopts residual heat recycling technology, which far saving energy consumption and low down the running cost. The gas produced by the production line will be purified to meet the environmental standard then discharged.

Continuous scrap tire pyrolysis production line advantages

Continuous scrap tire pyrolysis production line advantage

Continuous scrap tire pyrolysis production line advantage

Safety:

1.Reactorwithautoweldingtoguaranteethequalityofweldingseamandavoidcracking

2.Professionalheatingtreatmentandx-raydetectionchamberforweldingseam.

3.Vacuumsystemtopreventoilgasbebacktoreactorcausingaccident.

4.withtemperaturemeter,pressuremeterandsafetyvalve.

Environmentfriendly:

1.Dedustingsystemtopreventgasanddustfromcoalburning

2.Theexhaustgaswillberecycledforheatingreactor,nogaspollution

3.Wellsealingoneveryjunctionpartstopreventgasleak,nosmelly

Longerlife:

1.useQ245Rspecialsteelplate,thickness16mm.weldingseamwithautoweldingandwillgetheatingtreatmentandx-raydetectiontoextendthelifeofreactortothemostextend.

2.Thelifewillbe6-8years

Energysaving:

1.Wellsealingforheatingsystem,nogasleakandsavingfuel

Contact DOING experts and learrn how we can service your needs.