Product

Product

Waste plastic pyrolysis plant is a new method to recycle plastic safely and environmentally. By using the waste plastic pyrolysis plant, we can get fuel oil from the plastic waste, and we can also get the carbon black and combustible gas, all of which have a wide range of applications.

Waste plastic pyrolysis plant and end products

Waste plastic pyrolysis plant and end products

According to the demands of different customers, DOING provide different capacity of waste plastic pyrolysis plant for customers, including 1T, 5T, 10T, 12T, 15T. Among them, 12T and 15T are our best-selling models.

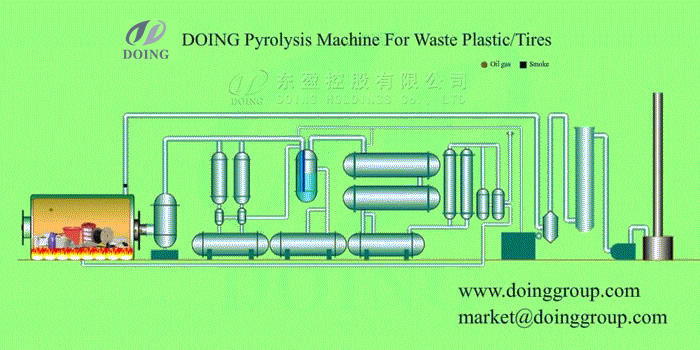

How Does the Waste Plastic Pyrolysis Plant Work?

The pyrolysis process of waste plastic pyrolysis plant

The pyrolysis process of waste plastic pyrolysis plant

1. Before put the waste plastic into the pyrolysis reactor, you need make sure that the water content can reach the standard. Otherwise, you should dry it first.

2. Heat the pyrolysis reactor with fuel, coal, or Natural gas. When the temperature reaches a certain degree, the oil gas will be produced. The most appropriate oil produced temperature is about 300 degrees Celsius.

3. The oil gas will flow into the cooling system and be cooled into a liquid oil.The un-combustible gas produced will be processed by the hydroseal, then it can heat the reactor.

4. Last, When the temperature in the reactor drops,carbon black can be discharged.

Contact DOING experts and learrn how we can service your needs.