Product

Project Case

-

-

DOING Three 15-ton Batch Tire Pyrolysis Units in Myanmar On-site Installation Experience

-

India 50TPD Fully continuous rubber pyrolysis machine installed

-

DOING 15 TPD semi-continuous tire pyrolysis equipment installed in Indonesia

-

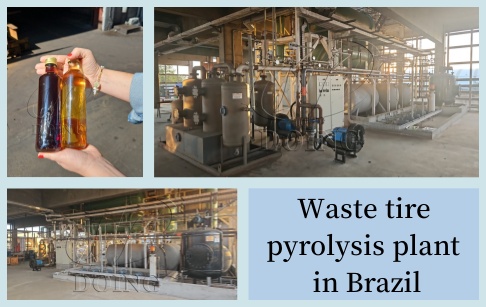

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

FAQ

-

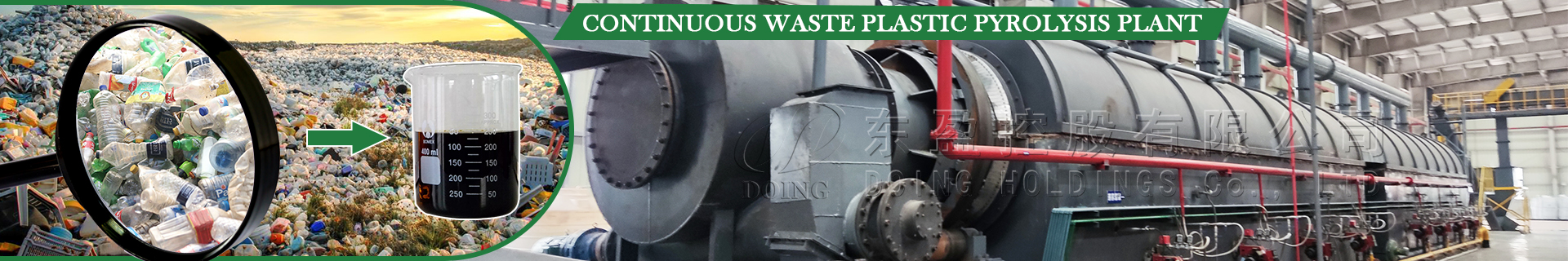

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

Automatic continuous plastic pyrolysis plant

DoingGroup has developed a new type of automatic continuous plastic pyrolysis plant. The automatic continuous plastic py...

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail: market@doingmachinery.com

E-mail: market@doingmachinery.com

- Features:

- Technical Data:

- Application:

Automatic continuous plastic pyrolysis plant

Automatic continuous plastic pyrolysis plant working process

1. The first plastic waste into plastic crusher, crushed waste plastic processing.

2. The broken plastic into the automatic continuous plastic pyrolysis plant.

3.Equipment produced in the reactor carbon black, will be automatically discharged at the end of the device.

Automatic continuous plastic pyrolysis plant

1. Accurately calculate the system to ensure full cracking, high oil yield.

2.Indirect heating, long service life.

3. Continuous feed. Continuous slag discharge, saving time and effort.

4. Automatic, PLC control, save manpower.

5. Pyrolysis reactor with internal rotation device, without the need for regular pause to replace the sealing material.

6. Single handling capacity, small land area.

- Features:

- Technical Data:

- Application:

| No. | Item | Specifications | ||||||

| 1 | Model | DY-C-10 | DY-C-20 | DY-C-30 | DY-C-50 | DY-C-60 | DY-C-80 | DY-C-100 |

| 2 | Cpacity | 10T/D | 20T/D | 30T/D | 50T/D | 60T/D | 80T/D | 100T/D |

| 3 | Power | 35Kw | 50Kw | 65Kw | 80Kw | 90Kw | 105Kw | 120Kw |

| 4 | Working type | Continuous | ||||||

| 5 | Reactor deisgn | Mutiple reactors (The quantity and size depends on the raw material condition) | ||||||

| 6 | Rotating | Internal rotating | ||||||

| 7 | Cooling system | Recycled waster cooling | ||||||

| 8 | Reactor material | Q245R/Q345R boiler plate | ||||||

| 9 | Heating method | Indireact hot air heating | ||||||

| 10 | Heating fuel | Fuel oil/gas | ||||||

| 11 | Feedstock | Waste tire/plastic/rubber | ||||||

| 12 | Output | Fuel oil, carbon black | ||||||

- Features:

- Technical Data:

- Application:

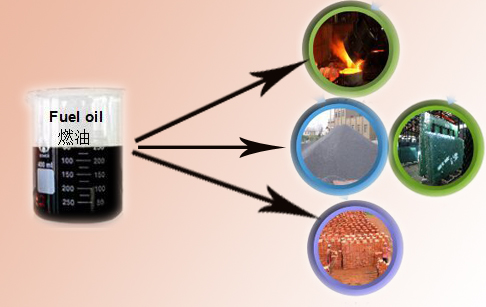

Fuel oil application

Carbon black application

3.Combustible gas will be reused mainly for heating the reactor through recycling.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.